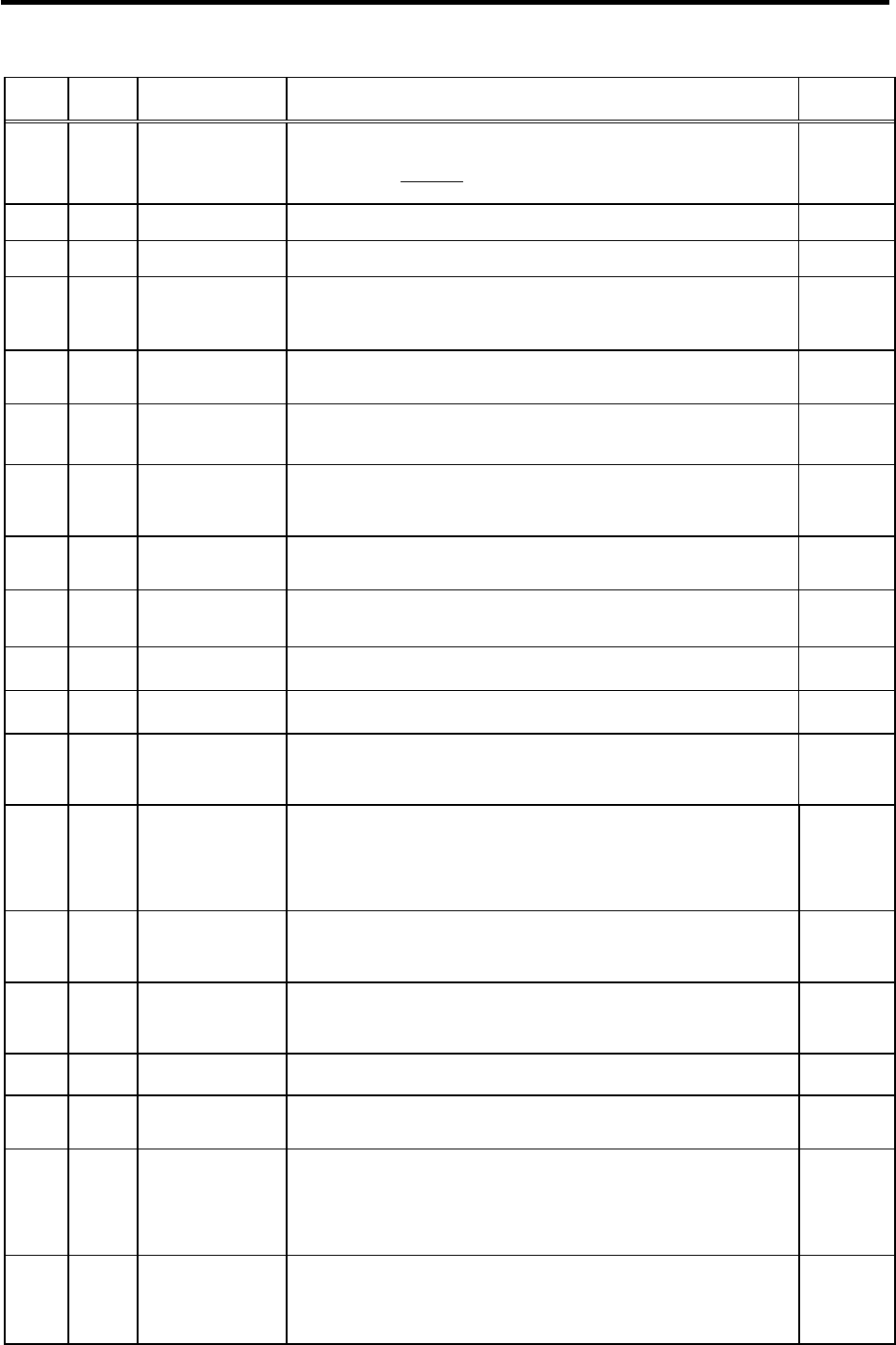

8. Setup

8 - 21

No. Abbrev. Parameter name Explanation

Setting range

(Unit)

Set "the motor inertia + motor axis conversion load inertia" in respect to the

motor inertia.

Jl+Jm Jm : Motor inertia

SV037 JL

Load inertia scale

SV037(JL) =

Jm

*100

Jl : Motor axis conversion load inertia

0 to 5000

(%)

SV038 FHz1

Notch filter

frequency 1

Set the vibration frequency to suppress if machine vibration occurs.

(Valid at 36 or more) When not using, set to "0".

0 to 4500

(Hz)

SV039 LMCD

Lost motion

compensation timing

Set this when the lost motion compensation timing doest not match.

Adjust by increasing the value by 10 at a time.

0 to 2000

(ms)

SV040 LMCT

Lost motion

compensation

non-sensitive band

Set the non-sensitive band of the lost motion compensation in the feed

forward control.

When "0" is set, the actual value that is set is 2m. Adjust by increasing by

1m at a time.

0 to 100

(m)

SV041 LMC2

Lost motion

compensation 2

Set this with SV016 (LMC1) only when you wish to set the lost motion

compensation amount to be different depending on the command directions.

Set to "0" as a standard.

-1 to 200

(Stall

current %)

SV042 OVS2

Overshooting

compensation 2

Set this with SV031 (OVS1) only when you wish to set the overshooting

compensation amount to be different depending on the command directions.

Set to “0” as a standard.

-1 to 100

(Stall

current %)

SV043 OBS1

Disturbance

observer filter

frequency

Set the disturbance observer filter band.

Set to "100" as a standard.

To use the disturbance observer, also set SV037 (JL) and SV044 (OBS2).

When not using, set to "0".

0 to 1000

(rad/s)

SV044 OBS2

Disturbance

observer gain

Set the disturbance observer gain. The standard setting is "100" to "300".

To use the disturbance observer, also set SV037 (JL) and SV043 (OBS1).

When not using, set to "0".

0 to 500

(%)

SV045 TRUB

Current

compensation

(the high order 8 bits)

Set "0" for the low order 8 bits.

Current bias:Use the high order 8 bits.(IB1)

Use this in combination with SV030 and the high order 8bits of SV040.

-32768

To

32767

SV046 FHz2

Notch filter

frequency 2

Set the vibration frequency to suppress if machine vibration occurs.

(Valid at 36 or more) When not using, set to "0".

0 to 4500

(Hz)

SV047 EC

Inductive voltage

compensation gain

Set the inductive voltage compensation gain. Set to "100" as a standard.

If the current FB peak exceeds the current command peak, lower the gain.

0 to 200

(%)

SV048 EMGrt

Vertical axis drop

prevention time

Input a length of time to prevent the vertical axis from dropping by delaying

Ready OFF until the brake works when the emergency stop occurs.

Increase the setting by 100msec at a time and set the value where the axis

does not drop.

0 to 20000

(ms)

SV049 PGN1sp

Position loop gain 1

in spindle

synchronous control

Set the position loop gain during the spindle synchronous control

(synchronous tapping, synchronous control with spindle/C axis).

Set the same value as the value of the spindle parameter, position loop gain

in synchronous control.

When performing the SHG control, set this with SV050 (PGN2sp) and

SV058 (SHGCsp).

1 to 200

(rad/s)

SV050 PGN2sp

Position loop gain 2

in spindle

synchronous control

Set this with SV049 (PGN1sp) and SV058 (SHGCsp) if you wish to perform

the SHG control in the spindle synchronous control (synchronous tapping,

synchronous control with spindle/C axis).

When not performing the SHG control, set to "0".

0 to 999

(rad/s)

SV051 DFBT

Dual feed back

control time constant

Set the control time constant in dual feed back.

When “0” is set, the actual value that is set is 1ms.

The higher the time constant is, the closer it gets to the semi-closed control,

so the limit of the position loop gain is raised.

0 to 9999

(ms)

SV052 DFBN

Dual feedback

control dead zone

Set the dead zone in the dual feedback control.

Set to “0” as a standard.

0 to 9999

(µm)

SV053 OD3

Excessive error

detection width in

special control

Set the excessive error detection width when servo ON in a special control

(initial absolute position setting, stopper control, etc.).

If "0" is set, excessive error detection won’t be performed.

0 to 32767

(mm)

SV054 ORE

Overrun detection

width in closed loop

control

Set the overrun detection width in the full-closed loop control.

If the gap between the motor side detector and the linear scale (machine

side detector) exceeds the value set by this parameter, it is judged to be

overrun and Alarm 43 will be detected.

When “-1” is set, the alarm detection won’t be performed. When “0” is set,

overrun is detected with a 2mm width.

-1 to 32767

(mm)

SV055 EMGx

Max. gate off delay

time after

emergency stop

Set the time from when emergency stop is input to when READY is forcibly

turned OFF.

Normally, set the same value as SV056.

When using vertical axis drop prevention control, the gate off will be delayed

by the time set in SV048 even if SV055 is smaller than SV048.

0 to 20000

(ms)