10. Troubleshooting

10 - 5

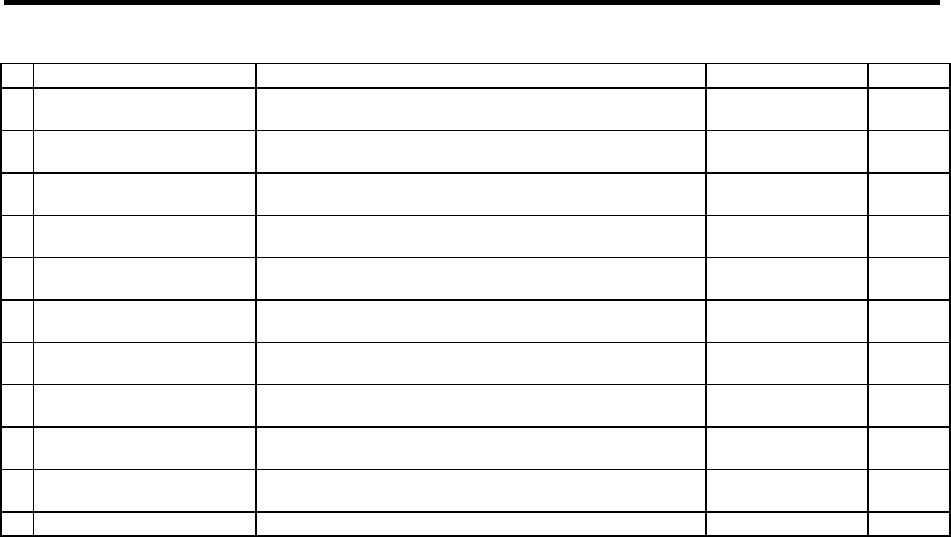

No. Alarm name Alarm details Stopping method Reset

43 Feedback error 2 An excessive difference in feedback was detected between the

sub side detector and the main side detector.

Dynamic brakes

PR

45 Fan stop A cooling fan built in the drive unit stopped, and the loads on the

unit exceeded the specified value.

Deceleration control

NR

46 Motor overheat Thermal protection function of the motor or in the detector, has

started its operation.

Deceleration control

NR

50 Overload 1 Overload detection level became over 100%. The motor or the

drive unit is overloaded.

Deceleration control

NR

51 Overload 2 Current command of more than 95% of the unit's max. current

was being continuously given for longer than 1 second.

Dynamic brakes

NR

52 Excessive error 1 A difference between the actual and theoretical motor positions

during servo ON exceeded the setting value.

Dynamic brakes

NR

53 Excessive error 2 A difference between the actual and theoretical motor positions

during servo OFF exceeded the setting value.

Dynamic brakes

NR

54 Excessive error 3 The anomalous motor current was detected at the detection of

Excessive error 1.

Dynamic brakes

NR

55 External emergency stop error There is no contactor shutoff command, even after 30 seconds

has passed since the external emergency stop was input.

Dynamic brakes

NR

5F External contactor error A contact of the external contactor is welding. Or the contactor

fails to be ON during ready ON.

Deceleration control

NR

88 Watchdog The system does not operate correctly. Dynamic brakes

AR

(Note) Definitions of terms in the table are as follows.

Main side detector: Detector connected to CN2 Sub side detector: Detector connected to CN3

Stopping method Deceleration control : The motor stops with the deceleration control time

constants set with the parameters (SV056).

Dynamic brakes : The dynamic brakes activate simultaneously with the

alarm occurrence to stop the motor.

Initial error : This alarm is detected before ready ON.

Resetting method NR : The alarm can be reset with the NC reset button. The alarm can also be

reset with the PR and AR resetting conditions.

PR : The alarm can be reset by turning the NC power OFF and ON. The alarm

can also be reset with the AR resetting conditions.

If the control axis is removed, the alarm can be reset with the NC reset

button. (Excluding alarms 32 and 37.)

AR : The alarm can be reset by turning the servo drive unit's power OFF and

ON.