Appendix 2. Selection

A2 - 4

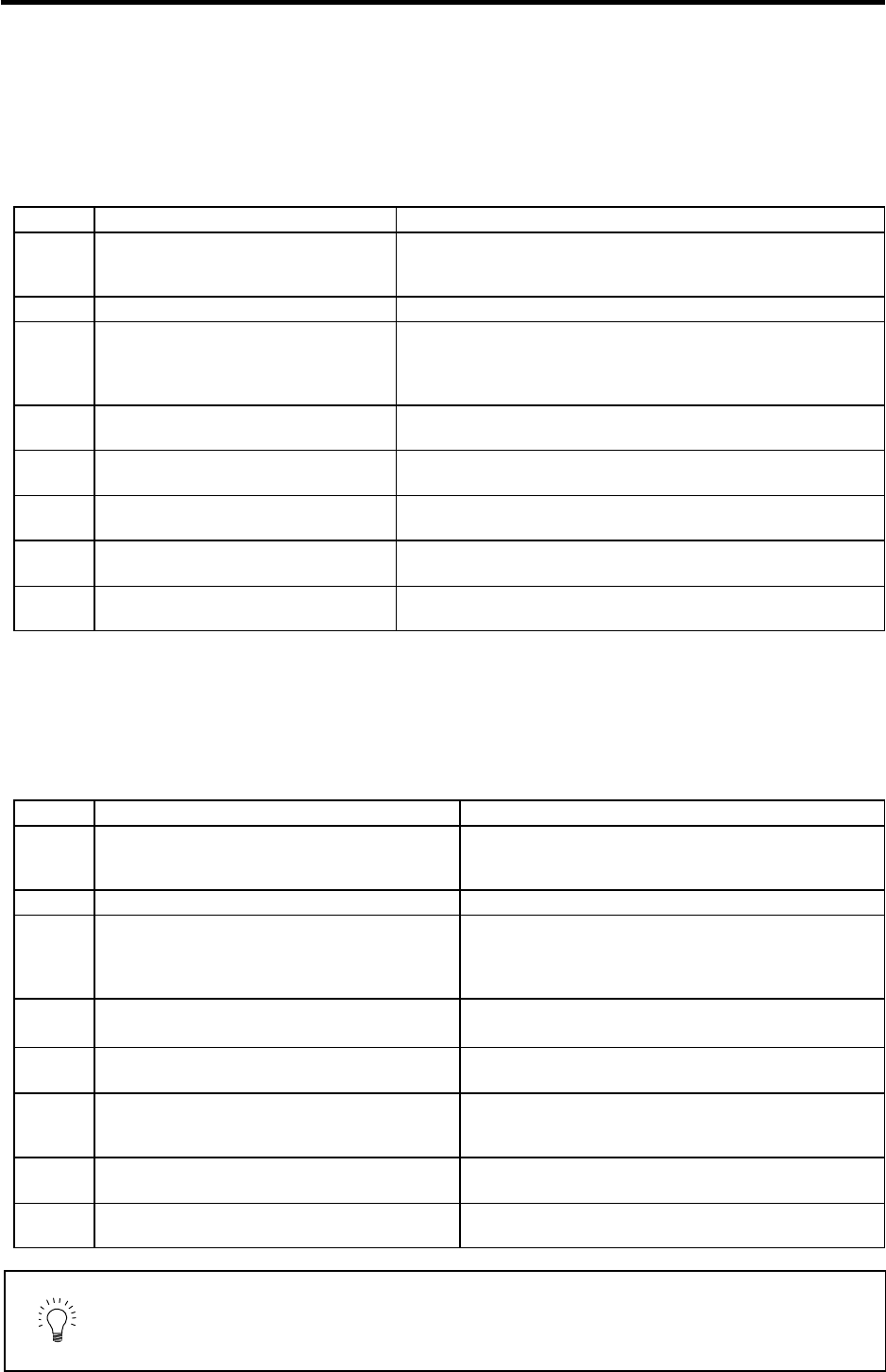

(1) Horizontal axis load torque

When operations <1> to <8> are for a horizontal axis, calculate so that the following torques are

required in each period.

Table 2-1 Load torques of horizontal axes

Period Load torque calculation method Explanation

<1>

(Amount of acceleration torque) +

(Kinetic friction torque)

Normally the acceleration/deceleration time constant is

calculated so that this torque is 80% of the maximum torque of

the motor.

<2> (Kinetic friction torque)

<3>

(Amount of deceleration torque) +

(Kinetic friction torque)

The absolute value of the acceleration torque amount is same

as that of the deceleration torque amount. The signs for the

amount of acceleration torque and amount of deceleration

torque are reversed.

<4> (Static friction torque)

Calculate so that the static friction torque is always required

during a stop.

<5>

(Amount of acceleration torque)

(Kinetic friction torque)

The signs are reversed with period <1> when the kinetic friction

does not change according to movement direction.

<6>

(Kinetic friction torque)

The signs are reversed with period <2> when the kinetic friction

does not change according to movement direction.

<7>

(Amount of deceleration torque)

(Kinetic friction torque)

The signs are reversed with period <3> when the kinetic friction

does not change according to movement direction.

<8>

(Static friction torque)

Calculate so that the static friction torque is always required

during a stop.

(2) Unbalance axis load torque

When operations <1> to <8> are for an unbalance axis, calculate so that the following torques are

required in each period. Note that the forward speed shall be an upward movement.

Table 2-2 Load torques of unbalance axes

Period Load torque calculation method Explanation

<1>

(Amount of acceleration torque) + (Kinetic

friction torque) + (Unbalance torque)

Normally the acceleration/deceleration time constant is

calculated so that this torque is 80% of the maximum

torque of the motor.

<2> (Kinetic friction torque) + (Unbalance torque)

<3>

(Amount of deceleration torque) + (Kinetic

friction torque) + (Unbalance torque)

The absolute value of the acceleration torque amount

is same as that of the deceleration torque amount. The

signs for the amount of acceleration torque and

amount of deceleration torque are reversed.

<4> (Static friction torque) + (Unbalance torque)

The holding torque during a stop becomes fairly large.

(Upward stop)

<5>

(Amount of acceleration torque) (Kinetic

friction torque) + (Unbalance torque)

<6>

(Kinetic friction torque) + (Unbalance torque)

The generated torque may be in the reverse of the

movement direction, depending on the size of the

unbalance torque.

<7>

(Amount of deceleration torque) (Kinetic

friction torque) + (Unbalance torque)

<8>

(Static friction torque) + (Unbalance torque)

The holding torque becomes smaller than the upward

stop. (Downward stop)

POINT

During a stop, the static friction torque may constantly be applied. The static

friction torque and unbalance torque may be applied during an unbalance axis

upward stop, and the torque during a stop may become extremely large.

Therefore, caution is advised.