Appendix 1. Cable and Connector Specifications

A1 - 2

Appendix 1-1 Selection of cable

Appendix 1-1-1 Cable wire and assembly

(1) Cable wire

The specifications of the wire used for each cable, and the machining methods are shown in this

section. When manufacturing the detector cable and battery connection cable, use the

recommended wires shown below or equivalent products.

(a) Heat resistant specifications cable

Wire characteristics

Wire type

(special order

part)

Finish

outer

diameter

Sheath

material

No. of

pairs

Configura-

tion

Conductive

resistor

Withstand

voltage

Insulation

resistance

Heat

resistance

temperature

Flexibility

2

(0.5mm

2

)

100 strands/

0.08mm

40.7/km

or less

BD20288

Compound 6-pair

shielded cable

Specification No.

Bangishi-17145

(Note 1)

8.7mm

Heat

resistant

PVC

4

(0.2mm

2

)

40 strands/

0.08mm

103/km

or less

500VAC/

1min

1000M/km

or more

105°C

7010

4

times

or more at

R200

(b) General-purpose heat resistant specifications cable

Wire characteristics

Wire type

(special order

part)

Finish

outer

diameter

Sheath

material

No. of

pairs

Configura-

tion

Conductive

resistor

Withstand

voltage

Insulation

resistance

Heat

resistance

temperature

Flexibility

2

(0.5mm

2

)

100 strands/

0.08mm

40.7/km

or less

BD20032

Compound 6-pair

shielded cable

Specification No.

Bangishi-16903

Revision No. 3

(Note 2)

8.7mm PVC

4

(0.2mm

2

)

40 strands/

0.08mm

103/km

or less

500VAC/

1min

1000M/km

or more

60°C

10010

4

times

or more at

R200

(Note 1) Bando Electric Wire (Contact: 81+48-461-0561 http://www.bew.co.jp)

(Note 2) The Mitsubishi standard cable is the (a) Heat resistant specifications cable. For MDS-C1/CH

series, (b) or equivalent is used as the standard cable.

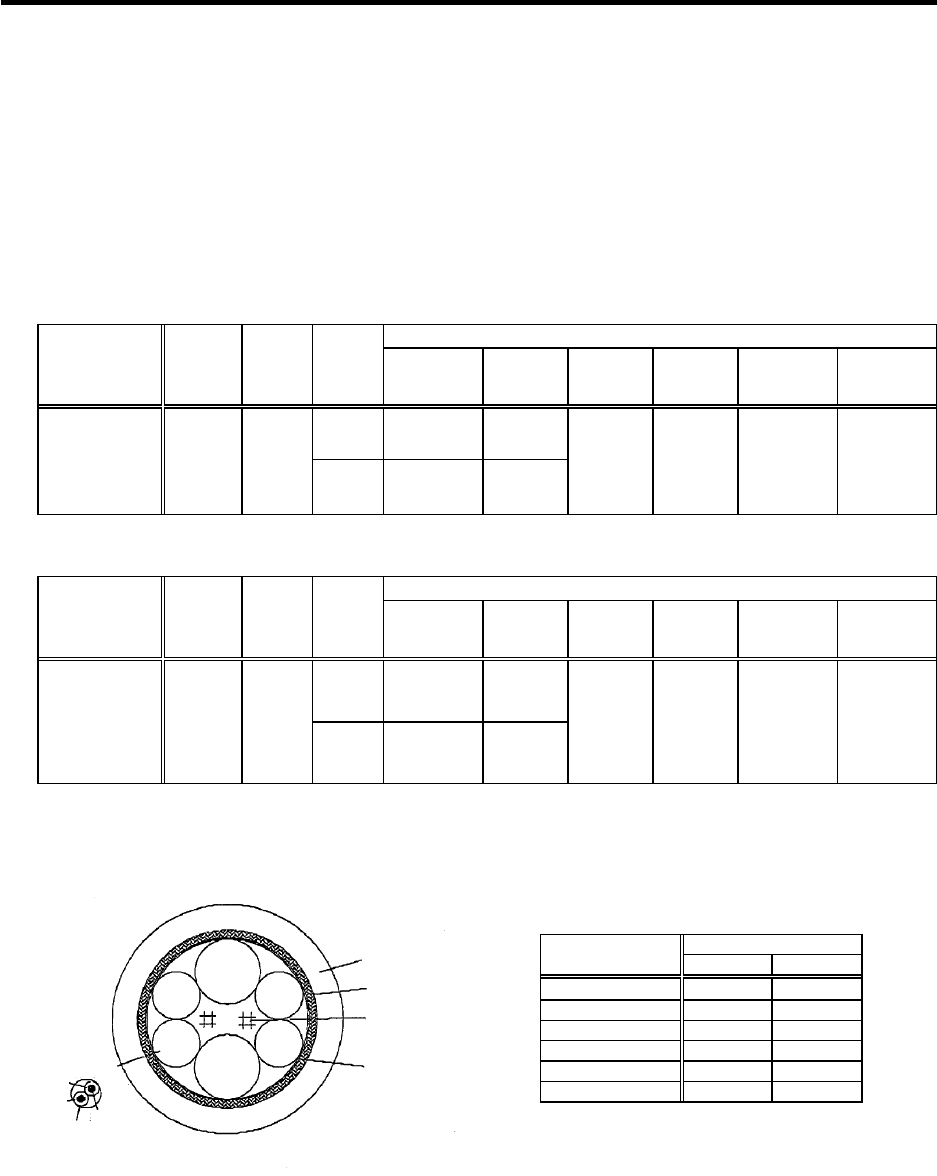

Sheath

Mesh shield

Intervening wire

Tape

A1

A2

B2

B1

B4

B3

Cable core

Conductor

Insulator

L2

L1

Compound 6-pair cable structure drawing

Core identification

Insulator color

Pair No.

L1 L2

A1 (0.5mm

2

)

Red White

A2 (0.5mm

2

)

Black White

B1 (0.2mm

2

)

Brown Orange

B2 (0.2mm

2

)

Blue Green

B3 (0.2mm

2

)

Purple White

B4 (0.2mm

2

)

Yellow White