9. Adjustment

9 - 7

9-2-3 Position loop gain

(1) Setting the position loop gain

The position loop gain (SV003 (PGN1)) is a parameter that determines the trackability to the

command position. 33 is set as a standard. Set the same position loop gain value between

interpolation axes.

When PGN1 is raised, the trackability will be raised and the settling time will be shortened, but a speed

loop that has a responsiveness that can track the position loop gain with increased response will be

required. If the speed loop responsiveness is insufficient, several Hz of vibration or overshooting will

occur during acceleration/deceleration. Vibration or overshooting will also occur when VGN1 is

smaller than the standard value during VIA adjustment, but the vibration in the position loop occurs

generally 10Hz or less. (The VIA vibration occurs from 10 to 20Hz.) When the position control includes

machine resonance points (Position control machine resonance points occur at the machine end

parts, etc.) because of insufficient machine rigidity, the machine will vibrate during positioning, etc. In

either case, lower PGN1 and adjust so that vibration does not occur.

If the machine also vibrates due to machine backlash when the motor stops, the vibration can be

suppressed by lowering the PGN1 and smoothly stopping.

If SHG control is used, an equivalently high position loop gain can be maintained while suppressing

these vibrations. To adjust the SHG control, gradually raise the gain from a setting where 1/2 of a

normal control PGN1 where vibration did not occur was set in PGN1. If the PGN1 setting value is

more than 1/2 of the normal control PGN1 when SHG control is used, there is an improvement

effect in position control. (Note that for the settling time the improvement effect is at 1/

2

or more.)

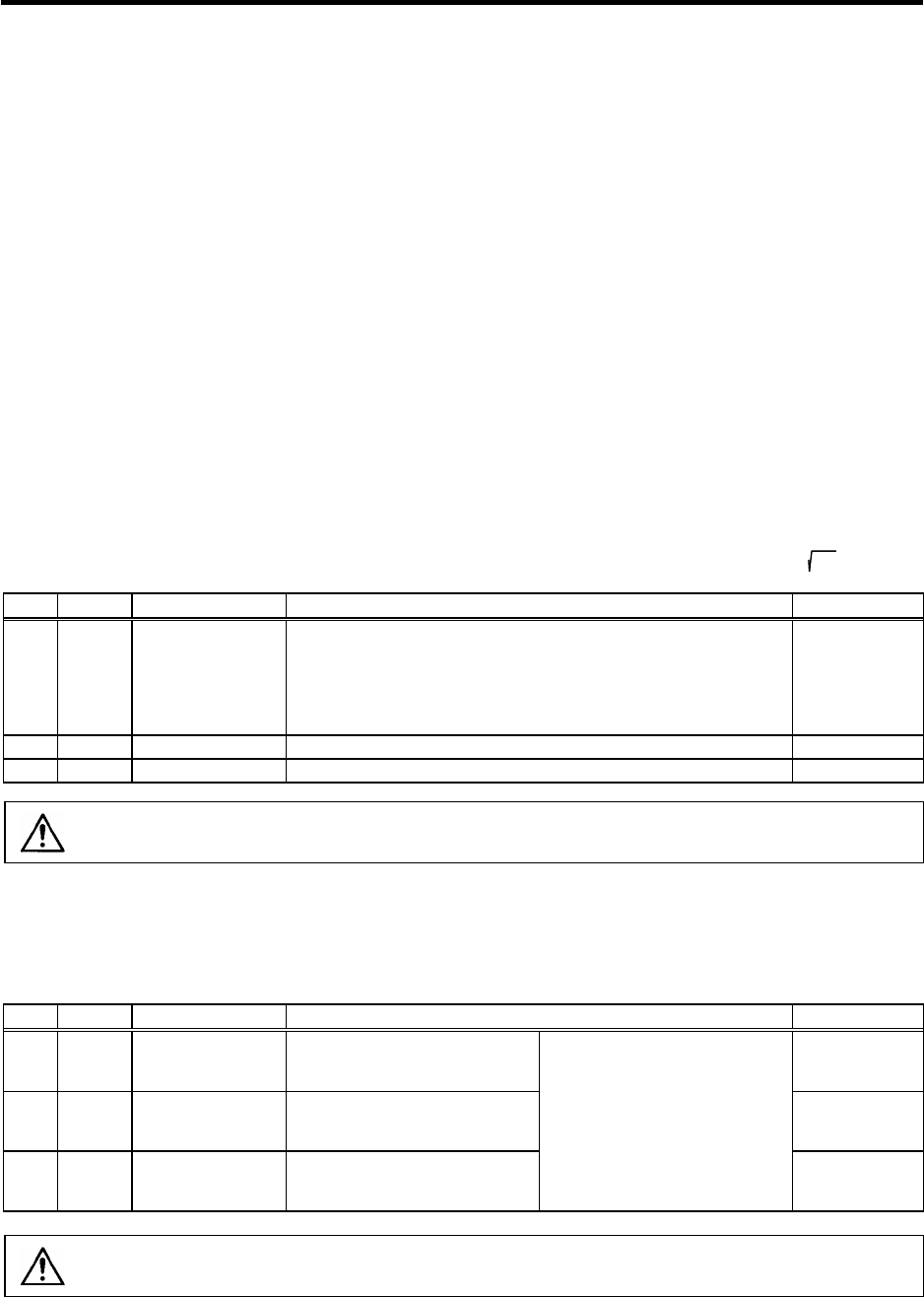

No. Abbrev. Parameter name Explanation Setting range

SV003 PGN1 Position loop gain 1

Set the position loop gain. The standard setting is "33".

The higher the setting value is, the more precisely the command can be

followed and the shorter the positioning time gets, however, note that a

bigger shock is applied to the machine during acceleration/deceleration.

When using the SHG control, also set SV004 (PGN2) and SV057

(SHGC).

1 to 200

(rad/s)

SV004 PGN2 Position loop gain 2 Set 0. (For SHG control) 0 to 999

SV057 SHGC SHG control gain Set 0. (For SHG control) 0 to 1200

CAUTION

Always set the same value for the position loop gain between the interpolation

axes.

(2) Setting the position loop gain for spindle synchronous control

During spindle synchronous control (synchronous tapping control, etc.), there are three sets of

position loop gain parameters besides the normal control.

No. Abbrev. Parameter name Explanation Setting range

SV049 PGN1sp Position loop gain 1

in spindle

synchronous control

Set 15 as a standard. 1 to 200

(rad/s)

SV050 PGN2sp Position loop gain 2

in spindle

synchronous control

Set 0 as a standard.

(For SHG control)

0 to 999

SV058 SHGCsp SHG control gain in

spindle synchronous

control

Set 0 as a standard.

(For SHG control)

Set the same parameter as the

position loop gain for the spindle

synchronous control.

0 to 1200

CAUTION

Always set the same value for the position loop gain between the spindle and

servo synchronous axes.