8. Setup

8 - 13

8-3 List of parameters

No. Abbrev. Parameter name Explanation

Setting

range (Unit)

SV001 PC1* Motor side gear ratio 1 to 32767

SV002 PC2*

Machine side gear

ratio

Set the motor side and machine side gear ratio.

For the rotary axis, set the total deceleration (acceleration) ratio.

Even if the gear ratio is within the setting range, the electronic gears may

overflow and cause initial parameter error (servo alarm No. 37).

1 to 32767

SV003 PGN1 Position loop gain 1

Set the position loop gain. The standard setting is "33".

The higher the setting value is, the more precisely the command can be

followed and the shorter the positioning time gets, however, note that a

bigger shock is applied to the machine during acceleration/deceleration.

When using the SHG control, also set SV004 (PGN2) and SV057 (SHGC).

1 to 200

(rad/s)

SV004 PGN2 Position loop gain 2

When using the SHG control, also set SV003 (PGN1) and SV057 (SHGC).

When not using the SHG control, set to "0".

0 to 999

(rad/s)

SV005 VGN1 Speed loop gain 1

Set the speed loop gain.

Set this according to the load inertia size.

The higher the setting value is, the more accurate the control will be,

however, vibration tends to occur.

If vibration occurs, adjust by lowering by 20 to 30%.

The value should be determined to be 70 to 80% of the value at the time

when the vibration stops.

1 to 999

VGN1

VGN2

VCS VLMT

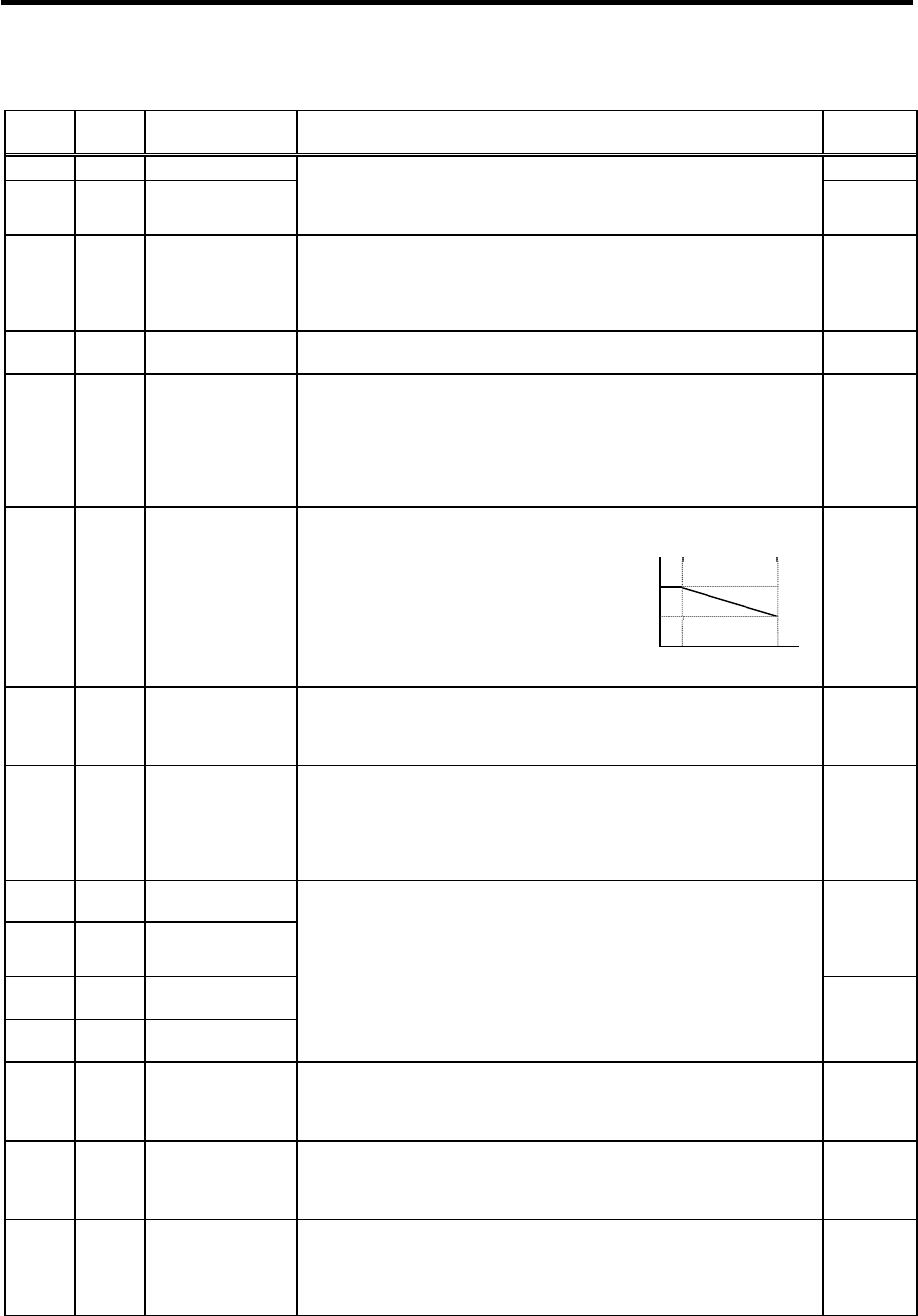

SV006 VGN2 Speed loop gain 2

If the noise is bothersome at high speed

during rapid traverse, etc, lower the speed

loop gain.

As in the right figure, set the speed loop

gain of the speed 1.2 times as fast as the

motor's maximum speed, and use this with

SV029 (VCS).

When not using, set to "0".

0

(Maximum speed*1.2)

-1000 to

1000

SV007 VIL

Speed loop delay

compensation

Set this when the limit cycle occurs in the full-closed loop, or overshooting

occurs in positioning.

When you set this parameter, make sure to set the torque offset (SV032

(TOF)). When not using, set to “0”.

0 to 32767

SV008 VIA

Speed loop lead

compensation

Set the gain of the speed loop integration control.

The standard setting is "1364". During the SHG control, the standard

setting is "1900". Adjust the value by increasing/decreasing it by about 100

at a time.

Raise this value to improve contour tracking precision in high-speed

cutting. Lower this value when the position droop vibrates (10 to 20Hz).

1 to 9999

SV009 IQA

Current loop q axis

lead compensation

SV010 IDA

Current loop d axis

lead compensation

Set the gain of current loop.

As this setting is determined by the motor's electrical characteristics, the

setting is fixed for each type of motor.

Set the standard values for all the parameters depending on each motor

type.

1 to 20480

SV011 IQG

Current loop q axis

gain

SV012 IDG

Current loop d axis

gain

1 to 4096

SV013 ILMT Current limit value

Set the normal current (torque) limit value. (Limit values for both + and -

direction.)

When the value is "500" (a standard setting), the maximum torque is

determined by the specification of the motor.

0 to 999

(Stall

current %)

SV014 ILMTsp

Current limit value in

special control

Set the current (torque) limit value in a special control (initial absolute

position setting, stopper control, etc). (Limit values for both of the + and -

directions.)

Set to "500" when not using.

0 to 999

(Stall

current %)

SV015 FFC

Acceleration rate

feed forward gain

When a relative error in the synchronous control is large, apply this

parameter to the axis that is delaying. The standard setting value is “0”.

For the SHG control, set to "100".

To adjust a relative error in acceleration/deceleration, increase the value by

50 to 100 at a time.

0 to 999

(%)

Parameters with an asterisk * in the abbreviation, such as PC1*, are validated with the NC power is turned ON again.