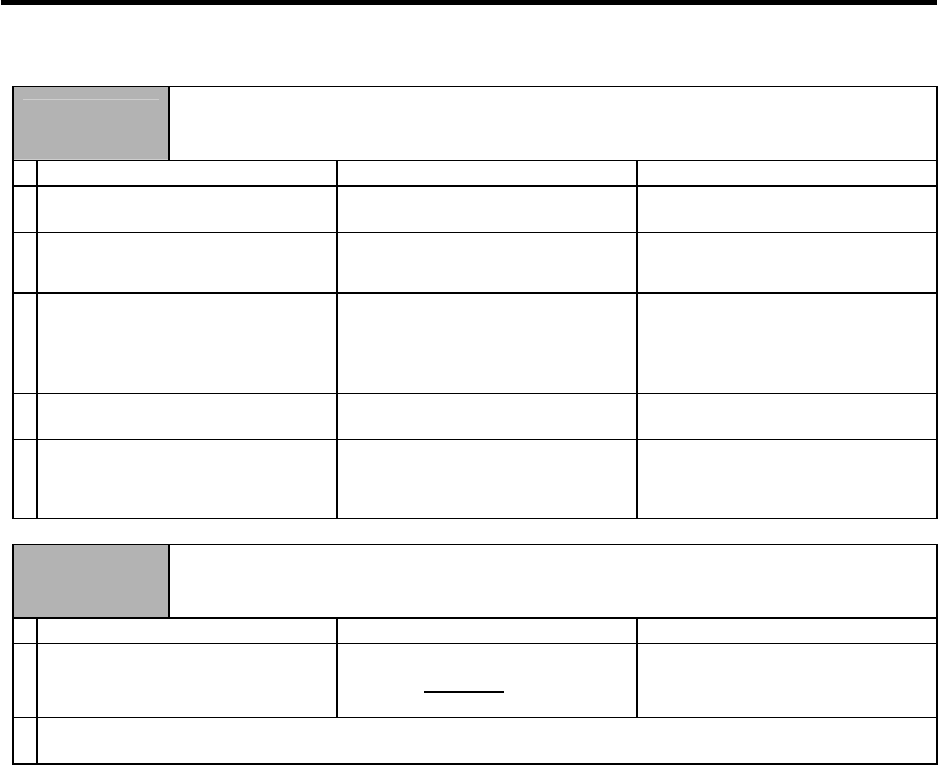

10. Troubleshooting

10 - 15

Alarm No.

51

Overload 2:

Current

command of more than 95% of the unit's max. current was being continuously given for longer

than 1 second.

Cause of occurrence Investigation items Remedy

1

The machine collided.

Check whether the machine collided. Check the cause of the collision.

2

The acceleration/deceleration time

constant is too short.

Is the current value on the NC servo

monitor screen abnormally large during

acceleration or deceleration?

Adjust the acceleration/deceleration

time constant.

3

Motor cable is incorrectly connected. Check the motor's power wire (U, V, W

phases).

The power wire is not connected.

Is the wire connected to another axis'

motor?

Correctly connect.

4

Detector is incorrectly connected.

Is the wire connected to another axis'

detector?

Correctly connect.

5

Detector is faulty.

Move the axis and check the FB signal. Replace the detector.

(When using the absolute position

system, the zero point must be

established again.)

Alarm No.

52

Excessive error 1:

A difference between the actual and theoretical motor positions during servo ON exceeded the setting

value.

Cause of occurrence Investigation items Remedy

Check the OD1 (SV023) setting value.

RAPID

1

The excessive error detection width is

too small.

Is OD1=

60PGN1

/ 2 satisfied?

Set the standard value according to the

rapid traverse rate and position loop gain.

2

Carry out the items for alarm No. 51.