10. Troubleshooting

10 - 16

Alarm No.

53

Excessive error 2:

A difference between the actual and theoretical motor positions during servo OFF exceeded the setting

value.

Cause of occurrence Investigation items Remedy

1

The axis moved during servo OFF.

Check the motor brake operation. Correctly and faulty sections.

2

The NC stopped the follow-up function

during servo OFF.

Check the NC parameters. Set the NC parameters according to the

machine specifications.

Check the OD1 (SV026) setting value.

RAPID

3

The excessive error detection width is

too small.

Is OD2=

60×PGN1

/ 2 satisfied?

Set the standard value according to the

rapid traverse rate and position loop gain.

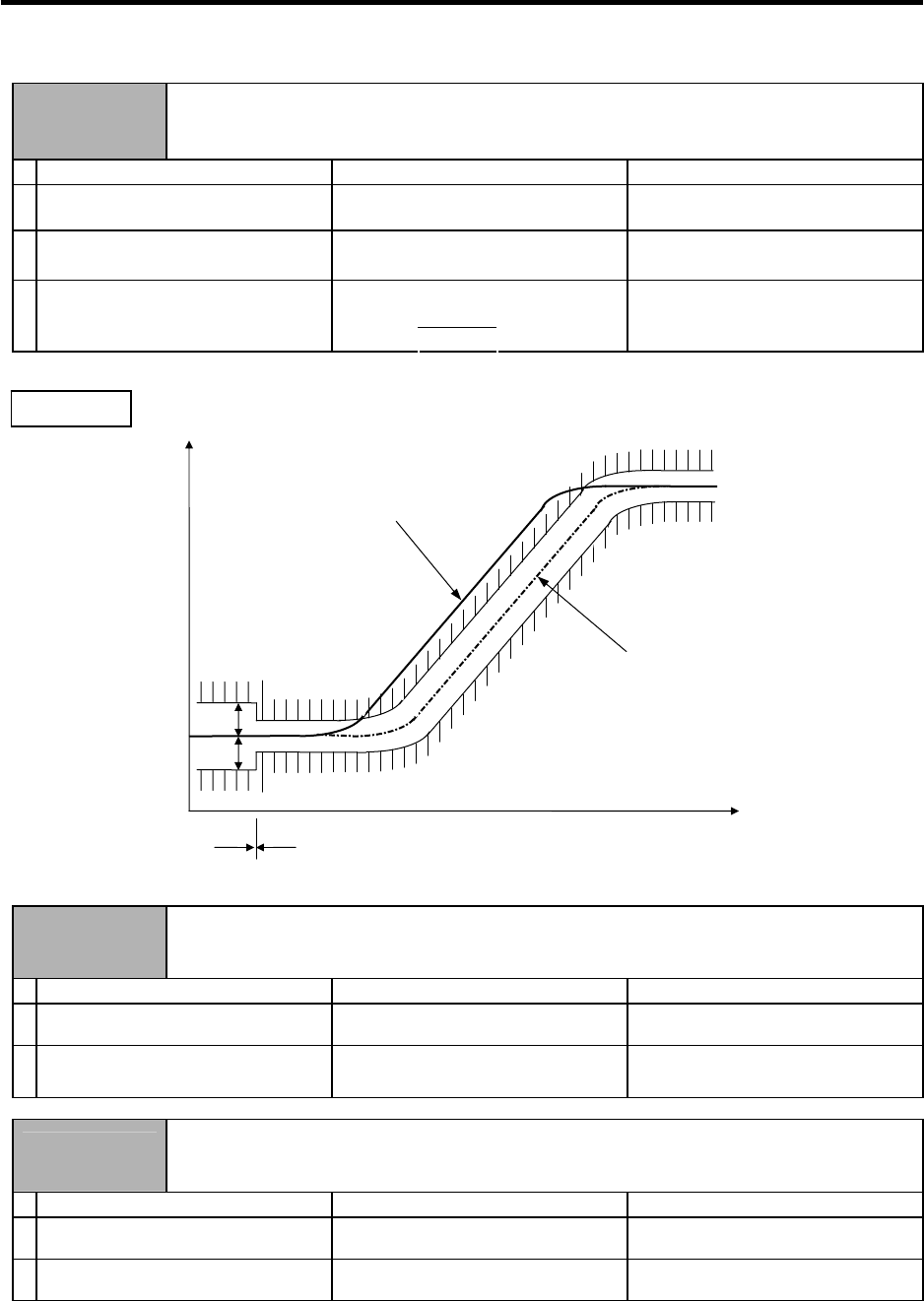

If the actual machine position is separated by the distance set with OD1 from the ideal machine position in

respect to the commanded position, the position will be within the shaded sections shown below.

Supplement

Alarm No.

55

External emergency stop error:

There is no contactor shutoff command, even after 30 seconds has passed since the external emergency

stop was input.

Cause of occurrence Investigation items Remedy

1

An error occurred during main

emergency stop.

Check the emergency stop input and

sequence program.

Improve the emergency stop sequence.

2

Parameters are incorrectly set. Check the PTYP (SV036) external

emergency stop setting.

Set correctly.

Alarm No.

5F

External contactor error:

A contact of the external contactor is welding. Or the contactor fails to be ON during ready ON.

Cause of occurrence Investigation items Remedy

1

The contactor turned ON during READY

OFF.

Check whether the contactor contact is

melted.

Replace the contactor.

2

The contactor turned OFF during ready

ON.

Check whether the contactor control

output connector (CN9) is disconnected.

Correctly connect.

Servo OFF

Servo ON

Time

OD2

OD2

Ideal machine position

Commanded position

OD1

OD1

Position