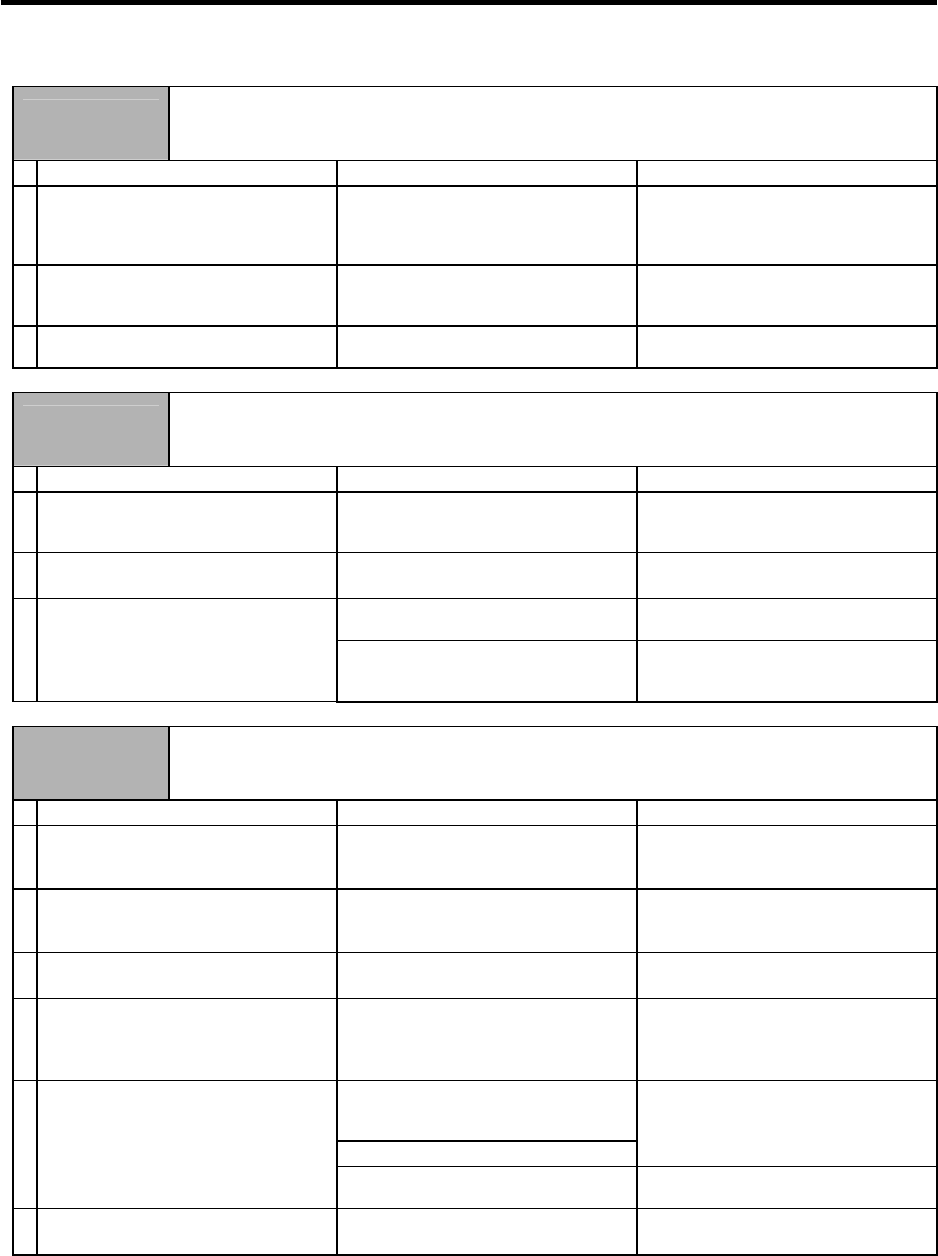

10. Troubleshooting

10 - 14

Alarm No.

45

Fan stop:

A cooling fan built in the drive unit stopped, and the loads on the unit exceeded the specified value.

Cause of occurrence Investigation items Remedy

1

The power is turned ON without assuring

more than 10 seconds for the time from

when the power is turned OFF till when it

is turned ON.

Are more than 10 seconds for the time

from when the power is turned OFF till

when it is turned ON assured?

Leave for more than 10 seconds, and

turn the power ON again.

If the fan is not rotating, check the

investigation item No. 2.

2

The connector connected to a fan is

disconnected.

Is the connector connected to a fan

disconnected?

Correctly connect the connector. If it is

correctly connected, check the

investigation item No. 3.

3

Oil or cutting chips are adhered to the fan. Is oil or cutting chips adhered to the fan?

Is the cable broken?

Improve the use environment and

replace the drive unit.

Alarm No.

46

Motor overheat:

Thermal protection function of the motor or in the detector, has started its operation.

Cause of occurrence Investigation items Remedy

1

The ambient temperature is high.

Is there a source of heat near the motor? Take care when arranging sources of

heat.

Provide means to shield heat.

2

The motor heat dissipation is poor.

Is the motor mounting flange thermally

shielded?

Provide means to dissipate heat from

flange.

Is unbalance torque large? Select the motor so that the unbalance

torque is 60% or less.

3

Motor load is large.

Was the overload alarm (50) forcibly

reset by turning the drive unit power

OFF?

Review the operation pattern.

Alarm No.

50

Overload 1:

Overload detection level became over 100%. The motor or the drive unit is overloaded.

Cause of occurrence Investigation items Remedy

1

Machine resonance is occurring. Is vibration noise heard?

Does the position droop fluctuate even

when the motor is stopped?

Adjust the parameters.

Select the notch filter.

Lower VGN1 (SV005).

2

Hunting is occurring. The axis is swaying or moving even

when the motor is stopped.

Adjust the parameters.

Increase VGN1 (SV005).

Lower VIA (SV008).

3

Motor performance is insufficient.

Review the motor capacity selection. Change the motor capacity.

4

The motor brakes are not released. Check the brake operation.

Check the brake relay.

Check the connector (CN9)

connection.

Correctly any faulty section.

Check the load current with the NC

servo monitor, and investigate the

machine load.

Is the ball screw bent?

Correct any faulty machine section.

5

An excessive force is applied from the

machine.

Is there interference with the positioning

pin?

When using the positioning pin, turn the

servo OFF while stopped.

6

Parameters are incorrectly set.

Are OLT (SV021) and OLL (SV022) set

to the standard values?

Set to the standard values.

(Note) PR resetting is not possible when the overload level is 50% or more. Do not forcibly reset (AR) by turning the unit power

OFF. If AR resetting is used at 50% or higher, the level is set to 80% when the power is turned ON next.