Workman HD SeriesPage 6 − 40Drive Train

5. Assemble differential gears:

A. Apply moly disulfide grease on pinion liners,

holes of pinion gears, side gear liners and hubs of

side gears.

B. Install side gear liners, side gears, pinion liners

and pinion gears.

C. Rotate side gears until holes of pinion gears and

liners align with holes of differential case.

D. Insert pinion shaft. Grease the shaft to aid as-

sembly.

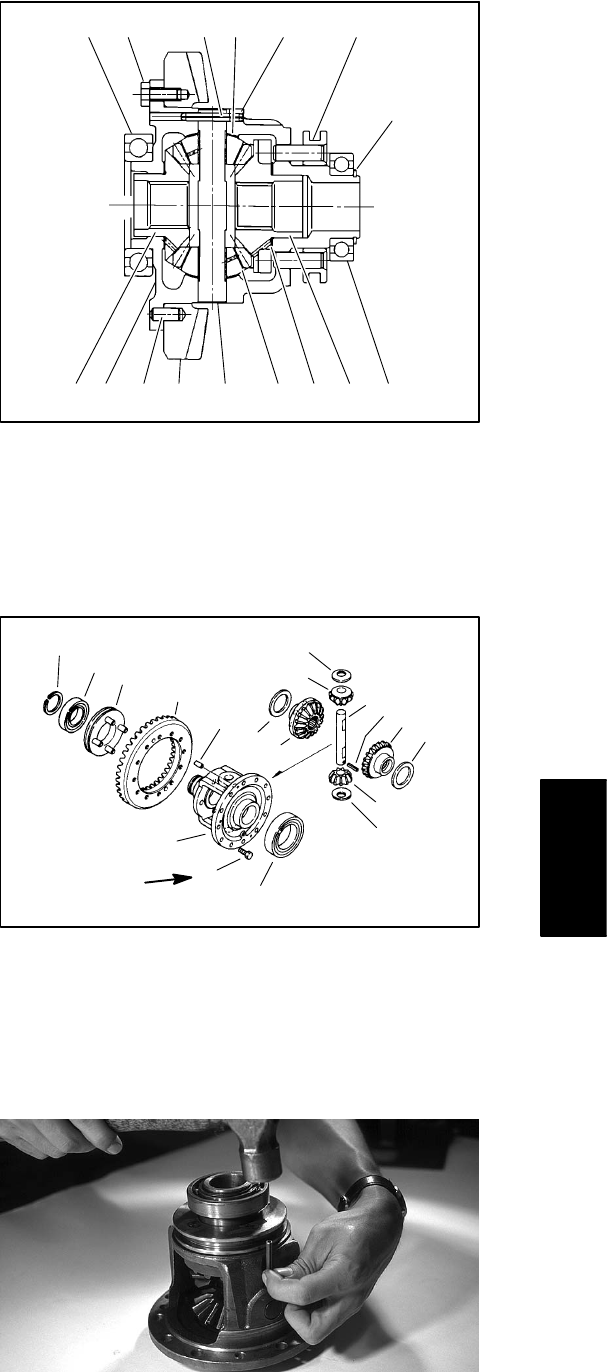

E. Assemble lock pin (Fig. 69). Drive the pin to the

approximate center location of the pinion mate shaft.

Pay attention to direction of slit in lock pin.

F. Check for smooth revolution of pinion gears and

side gears.

G. Completely clean oil from threads in ring gear.

NOTE: Ring gear and countershaft are supplied in

matched sets only.

H. Insert dowel pins onto ring gear.

I. Completely clean oil from threads of cap screws.

NOTE: It is recommended that whenever the ring

gear screws are removed that they be replaced with

new screws.

J. Apply Loctite to threads of cap screws.

K. Clean oil from contact surface of differential case

and ring gear.

L. Drive ring gear onto differential case.

M. Install and tighten cap screws to a torque from

18.5 to 22 ft−lb (24.5 to 29.5 N−m).

N. Use a press to install bearing onto differential

case.

O. Install slider. Put moly disulfide grease onto slid-

ing area of differential case before installing.

P. Use a press to install bearing.

Q. Install snap ring.

1. Bearing

2. Snap ring

3. Bearing

4. Slider

5. Screws

6. Ring gear

7. Dowel pin (2)

8. Lock pin

9. Pinion shaft

10. Pinion (2)

11. Liner (2)

12. L.H. side gear

13. R.H. Side gear

14. Liner (2)

Figure 67

1

15

5 SLIT 11 8 4

2

12 7 6 9 10 14 13 3

1. Bearing

2. Snap ring

3. Bearing

4. Slider

5. Screws

6. Ring gear

7. Dowel pin (2)

8. Lock pin

9. Pinion shaft

10. Pinion (2)

11. Liner (2)

12. L.H. side gear

13. R.H. Side gear

14. Liner (2)

2

3

4

6

7

11

10

14

13

9

8

12

14

10

11

1

5

15

Figure 68

18.5 to 22 ft−lb

(24.5 to 29.5 N−m)

Figure 69

Drive Train