Workman HD SeriesPage 9 − 40Hydraulic System

Primary Hydraulic System Gear Pump (Workman HD)

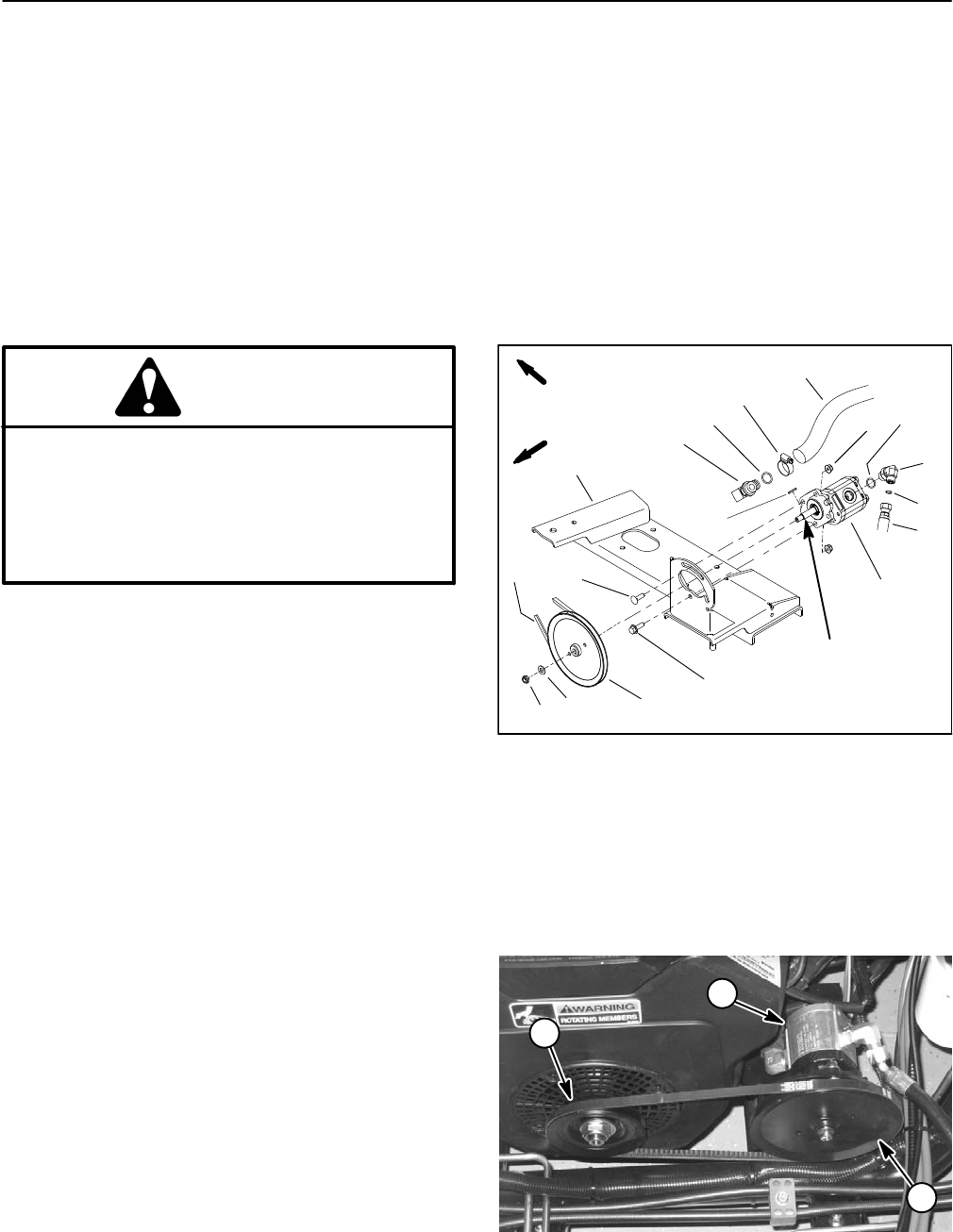

Removal (Fig. 29)

1. Park vehicle on a level surface, raise and support bed

(if installed), shut engine off and engage the parking

brake. Remove key from the ignition switch.

2. Loosen pump drive belt and remove belt from pump

pulley.

3. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of this chapter section.

CAUTION

Before performing any service or repair on hy-

draulic system components, relieve system

pressure to avoid injury from pressurized hy-

draulic oil. Stop the engine, remove key from the

ignition switch, rotate the steering wheel in both

directions, lower the bed onto the bed support

and operate other hydraulic accessories.

4. Disconnect hydraulic hoses from gear pump. Install

caps or plugs in hoses and pump fittings to prevent con-

tamination and leakage of hydraulic oil.

5. Remove gear pump from mount.

6. If hydraulic fittings are to be removed from gear

pump, mark fitting orientation to allow correct assembly.

Remove fittings from pump and discard O−rings.

Installation (Fig. 29)

1. If fittings were removed from gear pump, lubricate

and place new O−rings onto fittings. Install fittings into

pump openings using marks made during the removal

process to properly orientate fittings. Tighten fittings

(see Hydraulic Fitting Installation in the General Infor-

mation section of this chapter).

2. Install gear pump to mount (Fig. 29) using the follow-

ing instructions:

A. Apply antiseize lubricant to gear pump shaft be-

fore installing pulley.

B. Install pump suction hose to fitting on pump, then

fill pump through pressure port of pump, with clean

Dexron III ATF.

C. Install pump pressure hose to fitting on pump (see

Hydraulic Hose and Tube Installation in the General

Information section of this chapter).

3. After installing the pump and connecting hydraulic

hoses, install belt and adjust belt tension (see Opera-

tor’s Manual).

4. Check oil level in transaxle. Add Dexron III ATF if nec-

essary.

5. Start the engine and operate at idle speed until air is

out of hydraulic system.

6. Stop the engine and recheck oil level in transaxle.

Add Dexron III ATF if necessary.

9

6

7

8

1

10

11

3

5

2

12

4

15

16

13

17

14

18

ANTISIEZE

LUBRICANT

1. Drive belt

2. Lock nut

3. Flat washer

4. Pump pulley

5. Flange head screw

6. Carriage screw

7. Mount

8. Suction hose

9. Square key

10. Gear pump

11. Lock nut (2)

12. Pressure hose

13. Hose clamp

14. O−ring

15. Hydraulic fitting

16. O−ring

17. Hydraulic fitting

18. O−ring

Figure 29

FRONT

RIGHT

1. Gear pump

2. Pump pulley

3. Engine pulley

Figure 30

2

1

3