Workman HD Series Page 6 - 13 Drive Train

Removal (Fig. 7)

1. Park vehicle on a level surface, shut engine off and

remove key from ignition switch.

2. For driveshaft to be serviced, remove wheel, brake

caliper, brake rotor and wheel hub (see Wheel Hub Re-

moval in Chapter 7 - Chassis in this manual).

3. Loosen and remove flange nuts, cap screws and

hardened washers that secure driveshaft to transaxle

shaft (Fig. 8).

4. Slide driveshaft from transaxle shaft and remove

from vehicle.

5. If necessary, loosen and remove flange nut that se-

cures splined shaft to driveshaft. Remove splined shaft

from driveshaft.

NOTE: Spindle nuts are staked (deformed) to the

splined shaft during assembly. Clear away the deformed

area of the nut before removing the nut from the s haft or

damage to the shaft threads will occur.

Installation (Fig. 7)

1. If removed, attach splined shaft to driveshaft:

A. Apply antiseize lubricant to splined shaft and

install into driveshaft.

B. Apply Loctite #271 (or equivalent) to threads of

splined shaft.

C. Install new flange nut onto splined shaft and tight-

en. Torque spindle nut from 170to180ft-lb(231to

244 N- m).

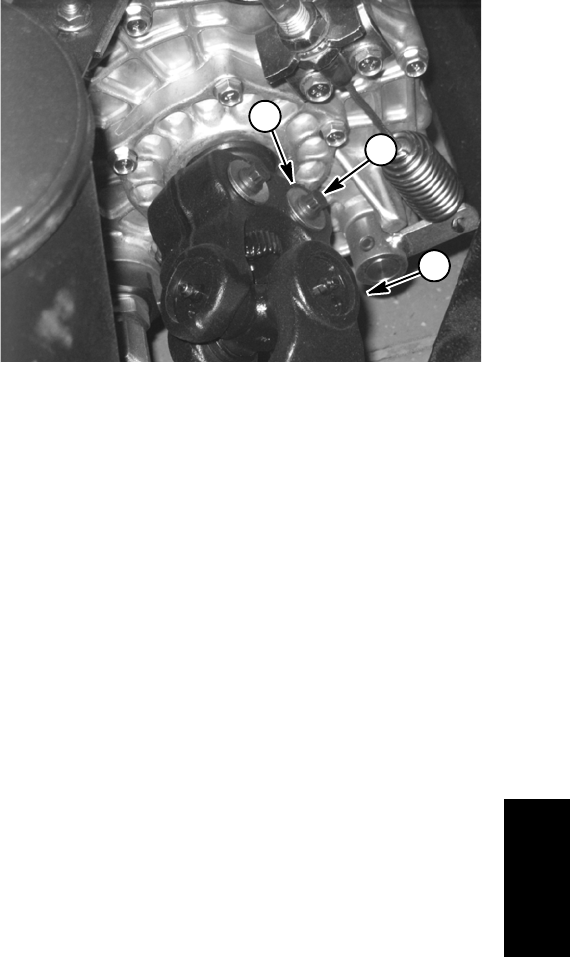

2. Secure driveshaft to transaxle shaft (Fig. 8):

A. Apply antiseize lubricant to transaxle shaft.

B. Slide driveshaft yoke onto transaxle shaft.

C. Align mounting holes in driveshaft with relief in

transaxle shaft.

D. Install cap screws, hardened washers and flange

nuts to secure driveshaft to transaxle shaft. Torque

fasteners from 40 to 45 ft- lb (55 to 61 N- m).

3. Install wheel hub, brake rotor, brake caliper and

wheel (see Wheel Hub Installation in the Service and

Repairs section of Chapter 7 - Chassis). Make sure that

wheel lug nuts are properly torqued from 80 to 90 ft- lb

(109 to 122 N- m).

4. Lubricate driveshaft grease fittings.

1. Driveshaft

2. Cap screw

3. Hardened washer

Figure 8

1

2

3

Drive Train