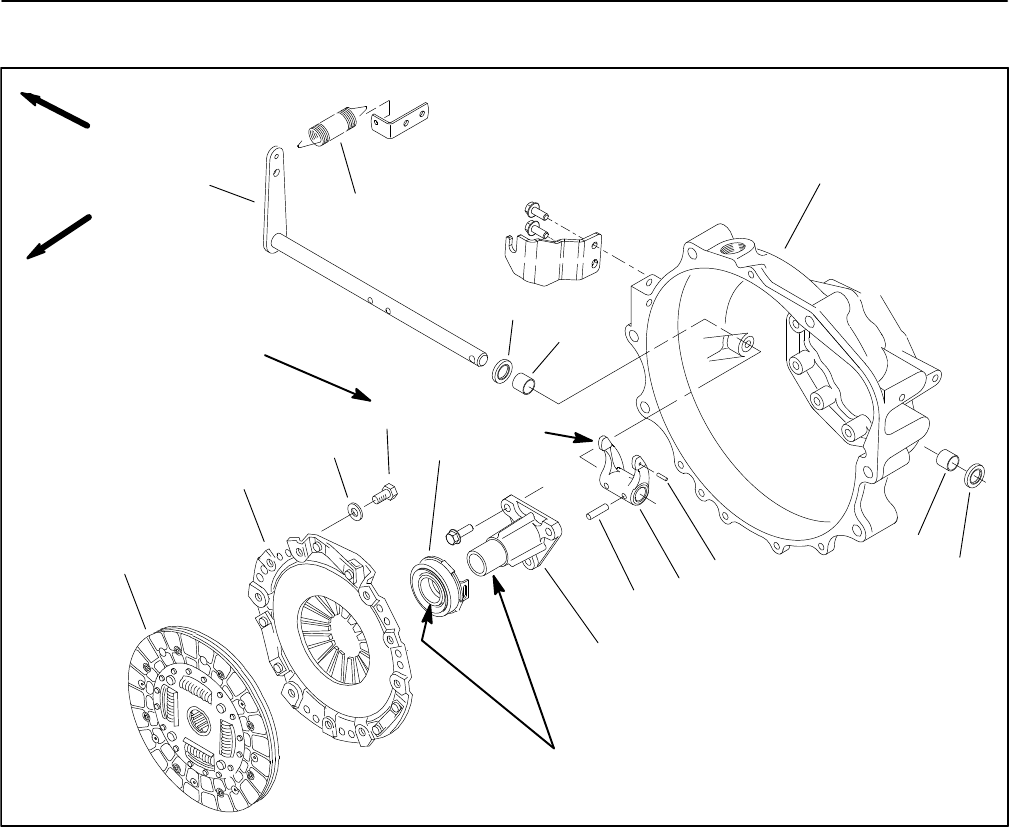

Workman HD SeriesPage 6 − 20Drive Train

Clutch Service

1. Spring pin

2. Throw out bearing

3. Release guide

4. Clutch release fork

5. Clutch release shaft

6. Bushing

7. Spring pin (2)

8. Bell housing

9. Oil seal

10. Cap screw (6)

11. Lock washer (6)

12. Pressure plate

13. Clutch disc

14. Extension spring

Figure 19

FRONT

RIGHT

5

9

6

1

4

3

2

9

6

13

12

11

10

5 to 7 ft−lb

(7 to 9 N−m)

7

8

14

Antiseize

lubricant

Antiseize

lubricant

NOTE: To perform the following clutch service proce-

dures, the transaxle needs to be removed from vehicle

(See Transaxle Removal in this section).

Clutch Release Mechanism (Fig. 19)

1. Inspect main shaft of transaxle for wear or damaged

splines.

2. Remove spring pin, then remove throw out bearing.

Inspect bearing and replace if it is loose on the sleeve,

if it appears burned or is worn. Make sure bearing slides

freely on release guide.

3. Inspect clutch release fork, release shaft and bush-

ings for wear or damage. Inspect extension spring. Re-

place worn or damaged parts. Replace oil seals.

4. During assembly, apply antiseize lubricant to the fol-

lowing:

A. Fill inside groove of throw out bearing and coat re-

mainder of bearing bore.

B. Apply thin coat to outside diameter of release

guide.

C. Apply thin coat to fingers of clutch release fork.

D. Remove any excess lubricant before final assem-

bly.