Workman HD SeriesPage 6 − 54Drive Train

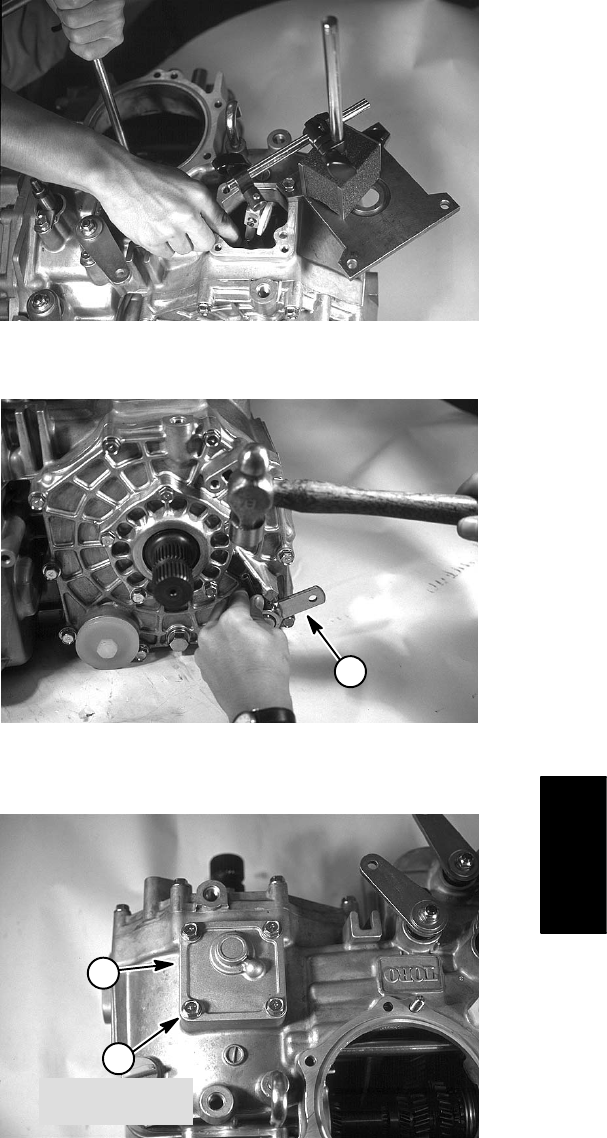

33.Measure backlash of ring gear through window on

transaxle case. Using a dial indicator, check ring gear

backlash in three equally spaced points. Backlash

should be 0.0031 to 0.0071 in. (0.08 to 0.18 mm) and

must not vary more than 0.0019 in. (0.05 mm) at the

points checked. If backlash is not in this range, replace

shim set in end of differential carrier:

A. If less than target range, decrease total thickness

of shim set until correct backlash is achieved.

B. If exceeds the target range, increase total thick-

ness of shim set until correct backlash is achieved.

NOTE: The thickest shim should be installed

against the bearing.

Figure 108

34.Install differential lock arm onto fork shaft. Insert lock

pin into fork shaft and arm. Pay attention to direction of

slit in lock pin.

1

1. Differential lock arm

Figure 109

35.Apply silicone sealant to mating surface of upper

cover. Pay attention to direction of cover and install. Se-

cure with flange head screws. Torque screws from 18.5

to 22 ft−lb (24.5 to 29.5 N−m).

1

2

1. Flange head screw (4) 2. Upper cover

Figure 110

18.5 to 22 ft−lb

(24.5 to 29.5 N−m)

Drive Train