Workman HD SeriesPage 8 − 18Electrical System

Relay (Five Terminals)

Workman HD series vehicles use a number of relays that

have five (5) terminals:

The start enable relay on Workman HD, HDX and

HDX−D vehicles ensures that the clutch pedal is de-

pressed before the engine starter can be engaged.

The start relay on Workman HD, HDX and HDX−D

vehicles ensures that the hydraulic lift lever is in

neutral before the engine starter solenoid can be en-

ergized.

The fan relay on Workman HDX and HDX−D ve-

hicles powers the engine cooling fan the relay is en-

ergized.

The ECU power relay on Workman HDX vehicles

supplies power to the engine Electronic Control Unit

(ECU), the fuel pump relay, the engine Oxygen (O2)

sensor, and the Electronic Throttle Valve (ETV) re-

lay.

The ETV relay on Workman HDX vehicles provides

power to the engine Electronic Throttle Valve (ETV)

through the engine Electronic Control Unit (ECU).

The fuel pump relay on Workman HDX vehicles al-

lows current to the fuel pump when the relay is ener-

gized.

The differential relay on Workman HDX 4WD and

HDX−D 4WD vehicles are used to make sure that

the front wheel drive differential solenoid is not ener-

gized when the clutch is disengaged or when the

brake is applied.

The kill relay on Workman HD vehicles allows the

engine to run as long as the relay is energized. If the

ignition switch is in the OFF position or the transmis-

sion lockout switches are all open, the relay will not

be energized and the engine will stop running.

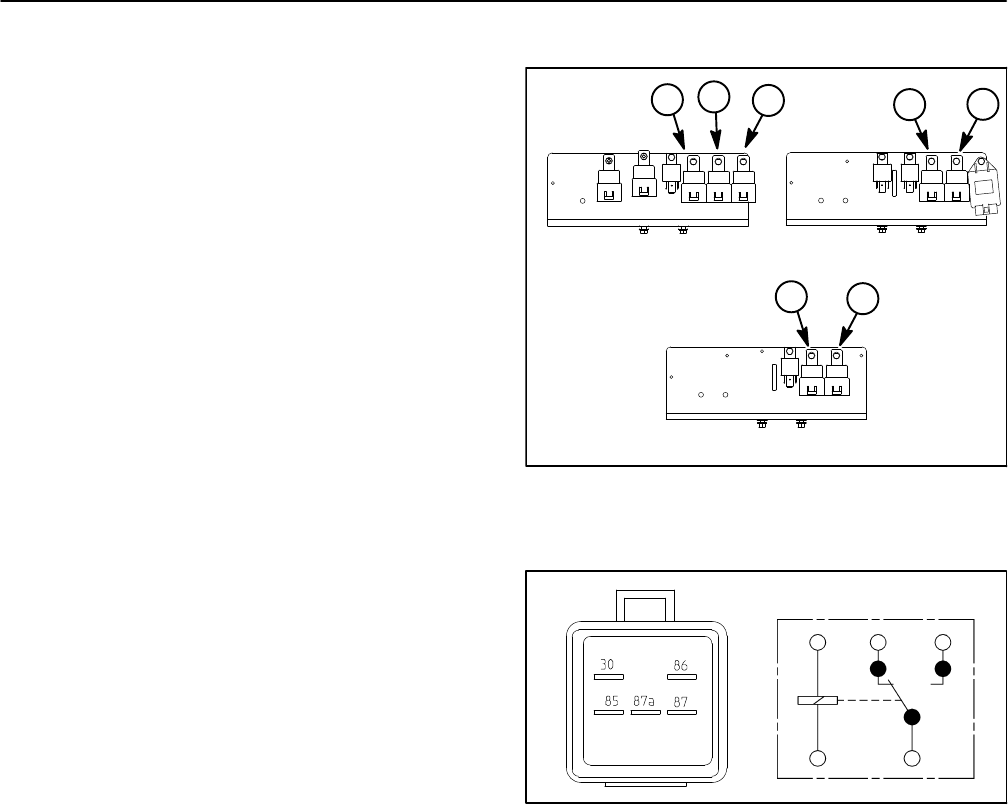

The start enable relay and the differential relay (4WD

vehicles) are located behind the dash panel. The other

relays are attached to the relay bracket under the right

side of the bed near the rear axle (Fig. 22).

Testing

1. Park machine on a level surface and apply parking

brake. If relay is located on relay bracket, raise bed and

install bed support on bed lift cylinder to prevent bed

from lowering. Stop engine and remove key from ignition

switch. If relay is located behind dash panel, remove

hood (see Hood Removal in Chapter 7 − Chassis).

1. Start relay

2. Fan relay

3. Fuel pump relay

4. Kill relay

Figure 22

HDX MODELS

HDX−D MODELS

HD MODELS

1

1

2

1

2

3

4

Figure 23

86

85

87A 87

30

2. Locate relay that is to be tested and disconnect the

wire harness connector from the relay. Remove relay

from machine for easier testing.

NOTE: Prior to taking small resistance readings with a

digital multimeter, short the meter test leads together.

The meter will display a small resistance value (usually

0.5 ohms or less). This resistance is due to the internal

resistance of the meter and test leads. Subtract this val-

ue from from the measured value of the component you

are testing.

3. Using a multimeter (ohms setting), measure coil re-

sistance between terminals 85 and 86 (Fig. 23). Resist-

ance should be between 70 and 90 ohms.