Using the Logic Editor

372 SPU 780 01EMAN May 2002 149

Sweep (Online Only)

Overview The Sweep function is a powerful diagnostic tool that lets you solve logic for a set

number of scans or solve logic continuously with a constant time between scans.

Constant Sweep

Mode

The Constant Sweep mode sets the controller to scan and solve logic and update I/

O continuously, but with a constant time interval between scans.

If the actual scan time is less than the imposed scan time, the controller waits for the

imposed scan time to elapse before performing the next scan. If the actual scan time

is more than the imposed scan time, the controller finishes the scan, then continues

on with the next scan. This lets you slow the scan time to when debugging logic, so

that the controller doesn’t solve logic too quickly for you to catch errors.

Performing a

Constant Sweep

From the networks panel (tree), right click menu:

Single Sweep Single Sweep mode sets the controller to scan and solve logic, and update I/O for a

set number of scans only. When the sweep is finished, the controller stops solving

logic and updating I/O, waits until you manually trigger the sweep.

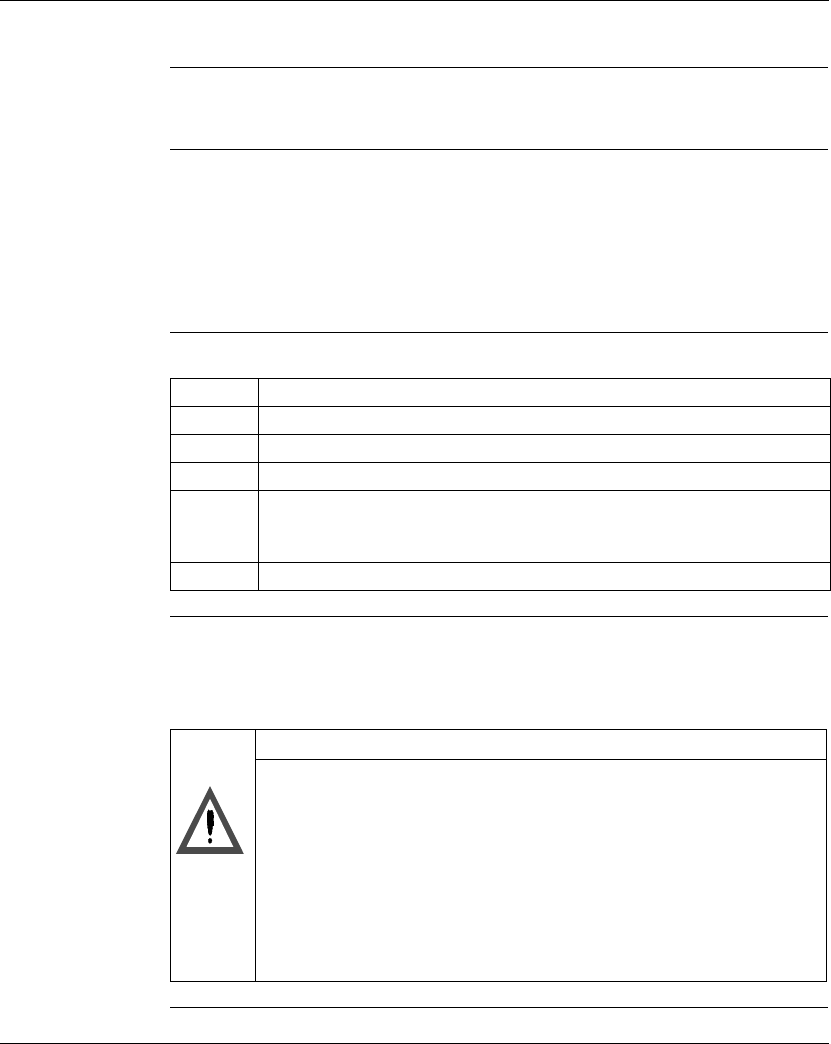

Step Action

1 Select Sweep.

2 In the Sweep Mode area, select the Constant Sweep radio button.

3 Enter the target time (in 10’s of milliseconds) for each scan in the Time box.

4 Enter a 4xxxx register to hold the target time value in the Register (4xxxx) box.

The actual time taken for each scan is placed in the next register, so a total of

two registers are used.

5 Click OK.

WARNING

Ensure hardware not part of critical process.

The Single Sweep function should not be used to debug controls on

machine tools, processes, or material handling systems when they are

active. Once the set number of scans is solved, all outputs are frozen in

their last state. Since no logic solving is occurring, all input information

is ignored. This can result in unsafe, hazardous, and destructive

operation of the machine or process connected to the controller.

Failure to follow this precaution can result in severe injury or

equipment damage.