Maintenance

6-6

AWG710 Service Manual

Interior Inspection. To access the inside of the waveform generator for inspection

and cleaning, refer to the Removal and Installation Procedures in this section.

Inspect the internal portions of the generator for damage and wear, using

Table 6–3 as a guide. Defects found should be repaired immediately.

CAUTION. To prevent damage from electrical arcing, ensure that circuit boards

and components are dry before applying power to the waveform generator.

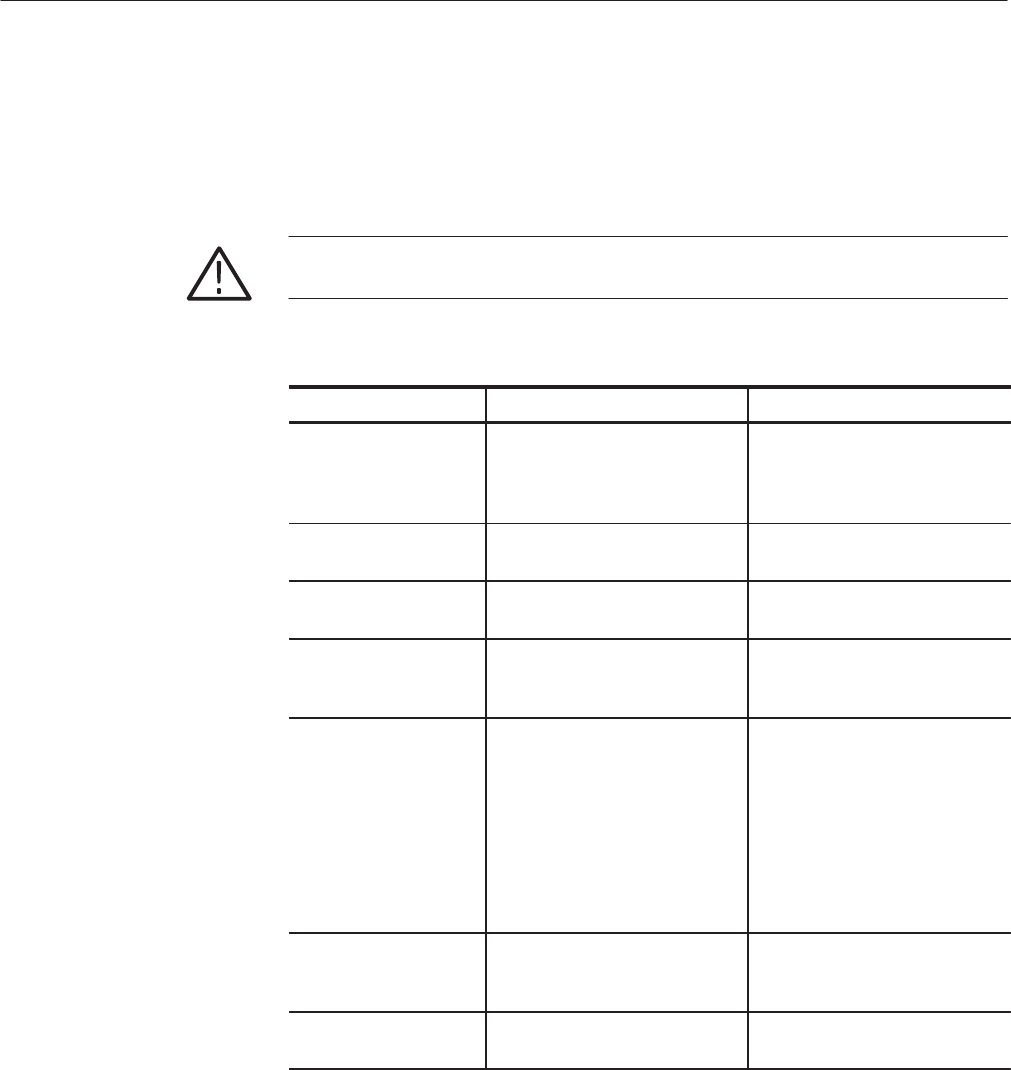

Table 6-3: Internal inspection check list

Item Inspect for Repair action

Circuit boards Loose, broken, or corroded

solder connections. Burned

circuit boards. Burned, broken, or

cracked circuitĆrun plating.

Remove failed module and

replace with a new module.

Resistors Burned, cracked, broken, blisĆ

tered condition.

Remove failed module and

replace with a new module.

Solder connections Cold solder or rosin joints. Re-solder joint and clean with

ethyl alcohol.

Capacitors Damaged or leaking cases.

Corroded solder on leads or

terminals.

Remove damaged module and

replace with a new module from

the factory.

Semiconductors Loosely inserted in sockets.

Distorted pins.

Firmly seat loose semiconducĆ

tors. Remove devices that have

distorted pins. Carefully straightĆ

en pins (as required to fit the

socket), using longĆnose pliers,

and reinsert firmly. Ensure that

straightening action does not

crack pins, causing them to

break off.

Wiring and cables Loose plugs or connectors.

Burned, broken, or frayed wiring.

Firmly seat connectors. Repair or

replace modules with defective

wires or cables.

Chassis Dents, deformations, and damĆ

aged hardware.

Straighten, repair, or replace

defective hardware.