7-176

CHKST,CHK

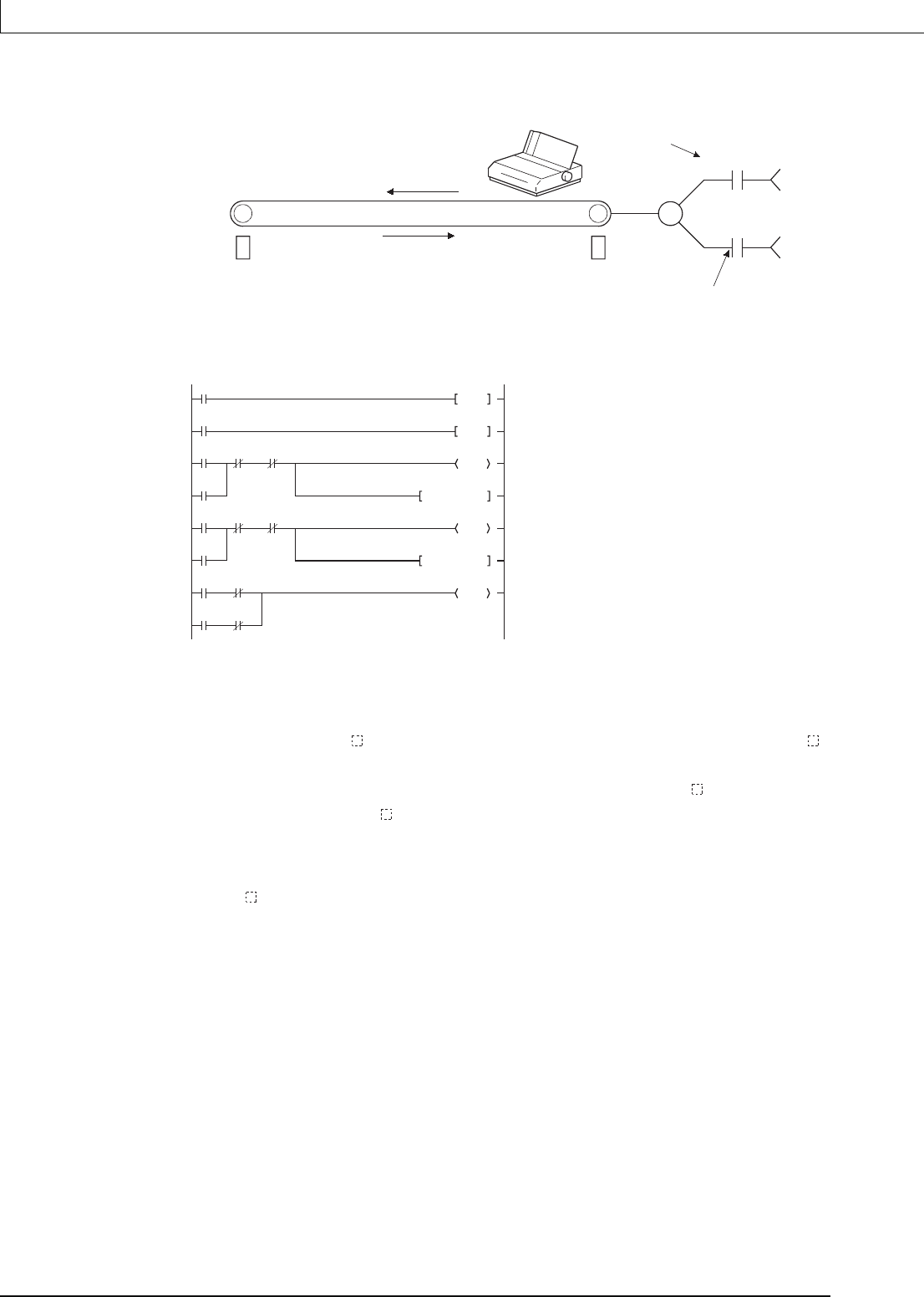

(b) The contact instruction prior to the CHK instruction does not control the execution of the

CHK instruction, but rather sets the check conditions.

(c) A ladder such as the one shown below can be created to perform a cycle time over

check for the system shown above:

(d) The following points should be taken into consideration when creating a ladder for use

with the CHK instruction:

1) The contact numbers for the advance edge detection sensor and the retract edge

detection sensor (X ) must always be continuous. Further, the contact number (X )

for the advance edge detection sensor should be lower than that for the retract edge.

2) Controls for the advance edge detection sensor contact number (X ) and output with

the identical number (Y )

*1

are as follows:

When advance operation is in progress ....turn ON

When retract operation is in progress........ turn OFF

*1: Output (Y ) is treated as an internal relay, and cannot be output to an external device.

Advance operation

M

Retract operation

(Y50)

(Y51)

Advance command (X4)

Retract command (X5)

A

dvance end sensor (X0)

turns ON at the detection

Retract end sensor (X1)

turns ON at the detection

Retract

Advance

Y

050

Y000

Y000

X004

CHK

X005 X000

Y051

X001

Y050

X000

CHKST

T0

Y050

X000

T0

Y051

Y051

X005 X004

X001

SET

RST

K100

When

T0 is OFF, program jumps to the instruction

next to the CHK instruction.

Executes CHK instruction when T0 is ON.

Advances conveyor 1.

Retracts conveyor 1.

Turns ON the internal relay used for failure detection.

Turns OFF the i

nternal relay used for failure detection.

check timer

Cycle time