12-66

12.1.7 Error code list (5000 to 5999)

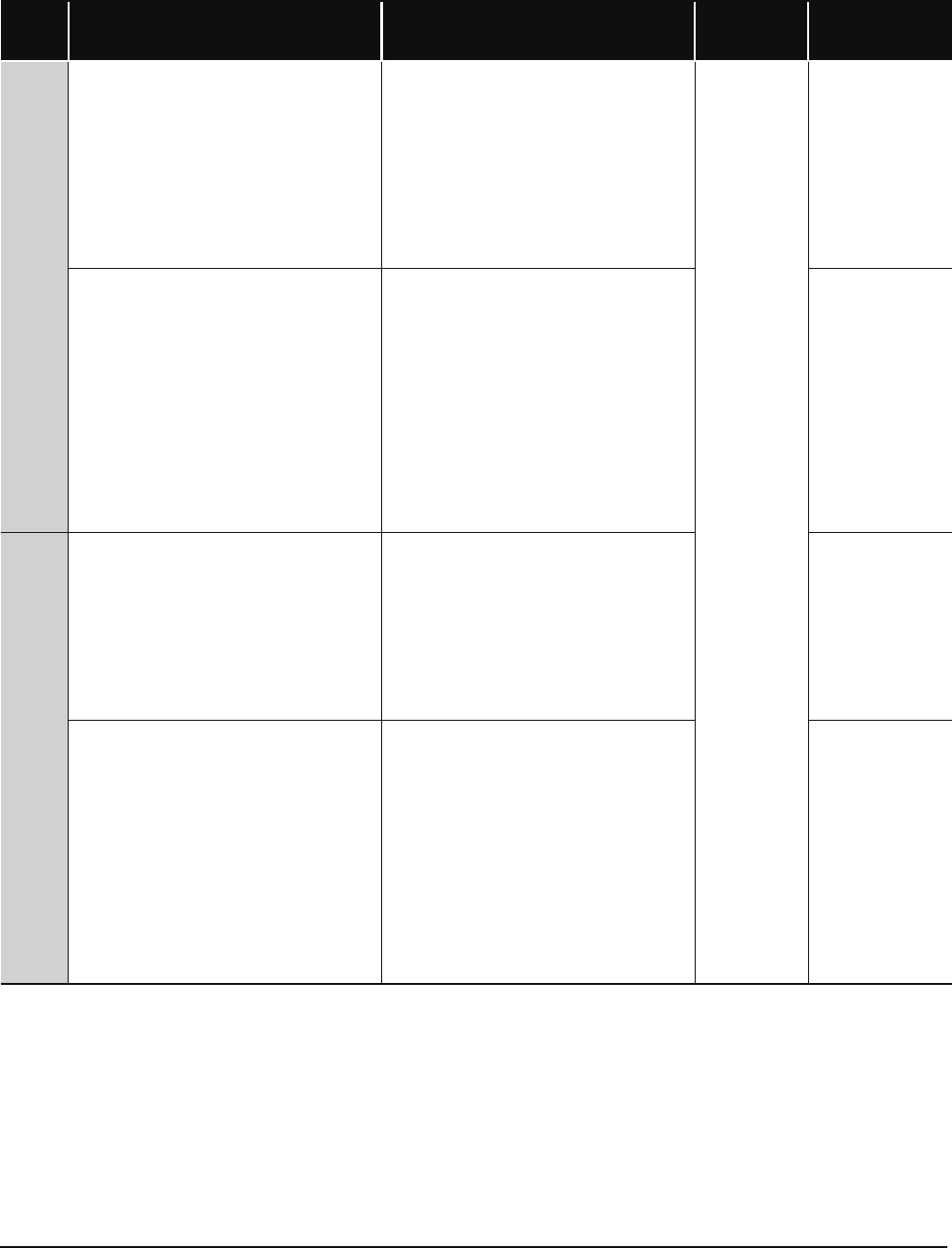

The following shows the error messages from the error code 5000 to 5999, the contents and

causes of the errors, and the corrective actions for the errors.

Error

Code

(SD0)

Error Contents and Cause Corrective Action

LED Status

CPU Status

Corresponding

CPU

5000

[WDT ERROR]

• The scan time of the initial execution type

program exceeded the initial execution

monitoring time specified in the PLC RAS setting

of the PLC parameter.

■Collateral information

• Common Information:Time (value set)

• Individual Information:Time (value actually

measured)

■Diagnostic Timing

• Always

• Read the individual information of the error from

the peripheral device, check its value (time), and

shorten the scan time.

• Change the initial execution monitoring time or

the WDT value in the PLC RAS setting of the

PLC parameter.

• Resolve the endless loop caused by jump

transition.

RUN:

Off

ERR.:

Flicker

CPU Status:

Stop

Qn(H)

QnPH

QnPRH

QnU

[WDT ERROR]

• The power supply of the standby system is

turned OFF.

• The tracking cable is disconnected or connected

without turning off or resetting the standby

system.

• The tracking cable is not secured by the

connector fixing screws.

■Collateral information

• Common Information:Time (value set)

• Individual Information:Time (value actually

measured)

■Diagnostic Timing

• Always

• Since power-off of the standby system increases

the control system scan time, reset the WDT

value, taking the increase of the control system

scan time into consideration.

• When the tracking cable is disconnected during

operation, securely connect it and restart the

CPU module. If the same error is displayed

again, the tracking cable or CPU module has a

hardware fault. (Contact your local Mitsubishi

representative, explaining a detailed description

of the problem.)

QnPRH

5001

[WDT ERROR]

• The scan time of the program exceeded the

WDT value specified in the PLC RAS setting of

the PLC parameter.

■Collateral information

• Common Information:Time (value set)

• Individual Information:Time (value actually

measured)

■Diagnostic Timing

• Always

• Read the individual information of the error using

the peripheral device, check its value (time), and

shorten the scan time.

• Change the initial execution monitoring time or

the WDT value in the PLC RAS setting of the

PLC parameter.

• Resolve the endless loop caused by jump

transition.

QCPU

[WDT ERROR]

• The power supply of the standby system is

turned OFF.

• The tracking cable is disconnected or connected

without turning off or resetting the standby

system.

• The tracking cable is not secured by the

connector fixing screws.

■Collateral information

• Common Information:Time (value set)

• Individual Information:Time (value actually

measured)

■Diagnostic Timing

• Always

• Since power-off of the standby system increases

the control system scan time, reset the WDT

value, taking the increase of the control system

scan time into consideration.

• When the tracking cable is disconnected during

operation, securely connect it and restart the

CPU module. If the same error is displayed

again, the tracking cable or CPU module has a

hardware fault. (Contact your local Mitsubishi

representative, explaining a detailed description

of the problem.)

QnPRH