7-177

CHKST,CHK

1

2

3

4

6

6

7

8

7.10 Debugging and failure diagnosis instructions

7.10.1 Special format failure checks (CHKST,CHK)

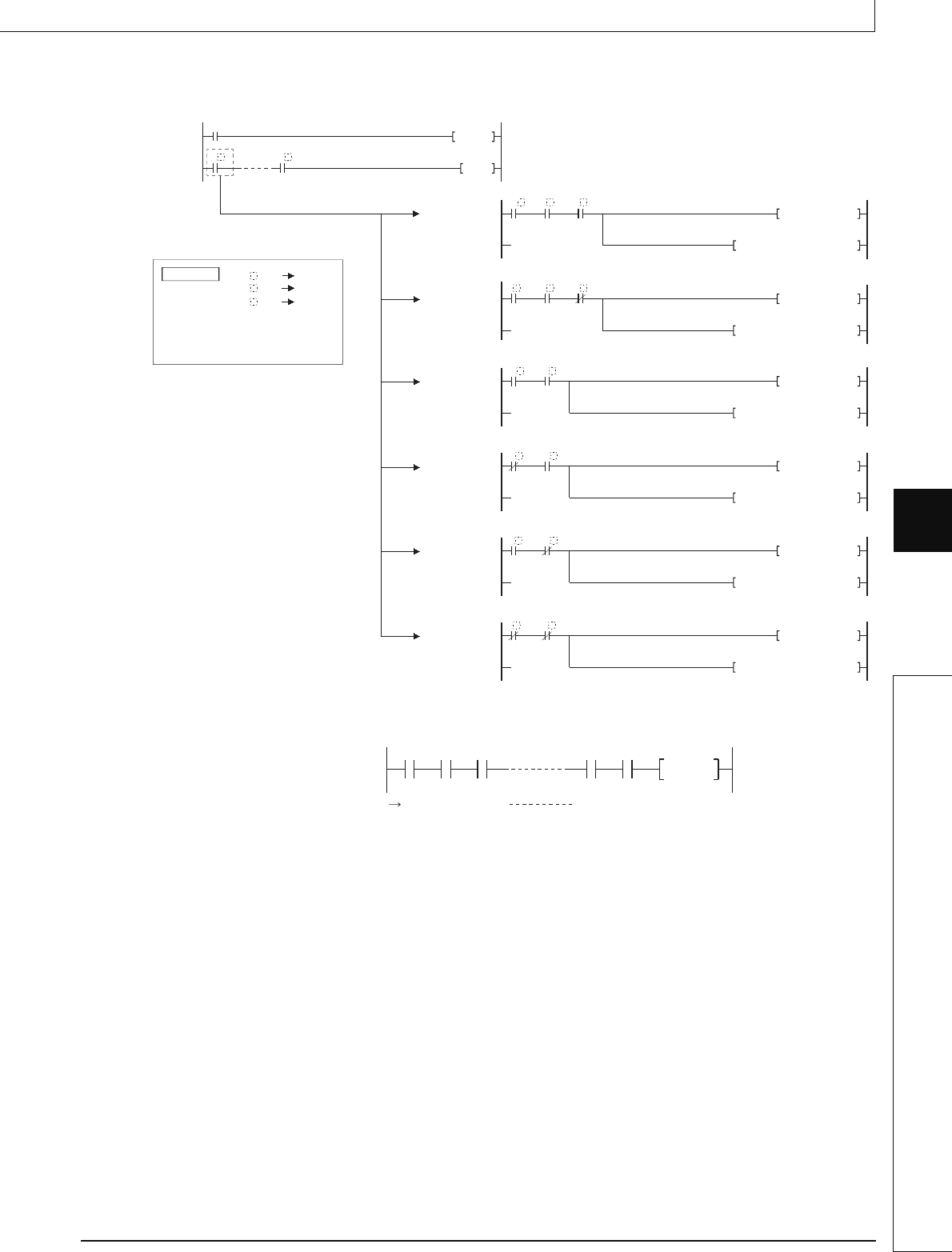

(2) Depending on the designated contact, the CHK instruction undergoes processing identical

to that shown for the ladder below:

(3) Numbers 1 to 150 from the vertical bus on the left side have been allocated as contact

numbers during failure detection.

(4) Reset SM80 and SD80 prior to forcing the execution of the CHK instruction.

After the execution of the CHK instruction, it cannot be performed once again until SM80

and SD80 have been reset.

(The contents of SM80 and SD80 will be preserved until reset by user.)

(5) A CHKST instruction must be placed before the CHK instruction.

An error will be returned if an instruction other than the LD, LDI, AND or ANI instruction is

used between the CHK instruction and the CHKST instruction. (Error code: 4235)

(6) The CHK instruction can be written at any step of the program.

However, there is a limit in the number of uses of the CHK instruction.

• Can be used up to two places in all program files being executed.

• Can be used only one place in a single program file.

An error will be returned if the CHK instruction is used exceeding the number of uses

specified above. (Error code: 4235)

SM80SET

MOV Failure No. 6 SD80

Y

X

Coil No. 6

CHK

CHKST

TO

SM80

X

X X +1 Y

X

+1

Y

SM80

SET

SET

MOV Failure No. 1 SD80

MOV Failure No. 2 SD80

SM80SET

MOV Failure No. 3 SD80

X

Y

(Detection by both advance and retraction end sensors

during advance operation of the conveyor)

(Detection by both advance and retraction end sensors

during retract operation of the conveyor)

(Advance operation of the conveyor at the detection

by the advance end sensor)

SM80

SET

MOV Failure No. 4 SD80

Y

X +1

(Retract operation of the conveyor at the detection

by the retraction end sensor)

SM80

SET

MOV Failure No. 5 SD80

Y

X +1

(Advance operation of the conveyor during no detection

by the retraction end sensor)

(Retract operation of the conveyer at the detection

by the advance end sensor)

Coil No. 1

Coil No. 2

Coil No. 3

Coil No. 4

Coil No. 5

Max. 150 contacts

Example

XX0

XX1

X

+ 1

YY0

X

Executes the same processing

as the ladder indicated above

CHK

X5 X7

X9

149 150123

Contact No.

X1A

X1C