5 - 18

5 PARAMETERS FOR POSITIONING CONTROL

5.3.2 S-curve ratio

S-curve ratio can be set as the acceleration and deceleration processing method for S-

pattern processing.

Setting range of the S-curve ratio is 0 to 100[%].

If it is set outside the range, an error occurs at the start and control is executed with the

S-curve ratio set as 100[%].

Errors are set in the servo program setting error area (D9190).

Setting of the S-curve ratio enables acceleration/deceleration processing to be

executed gently.

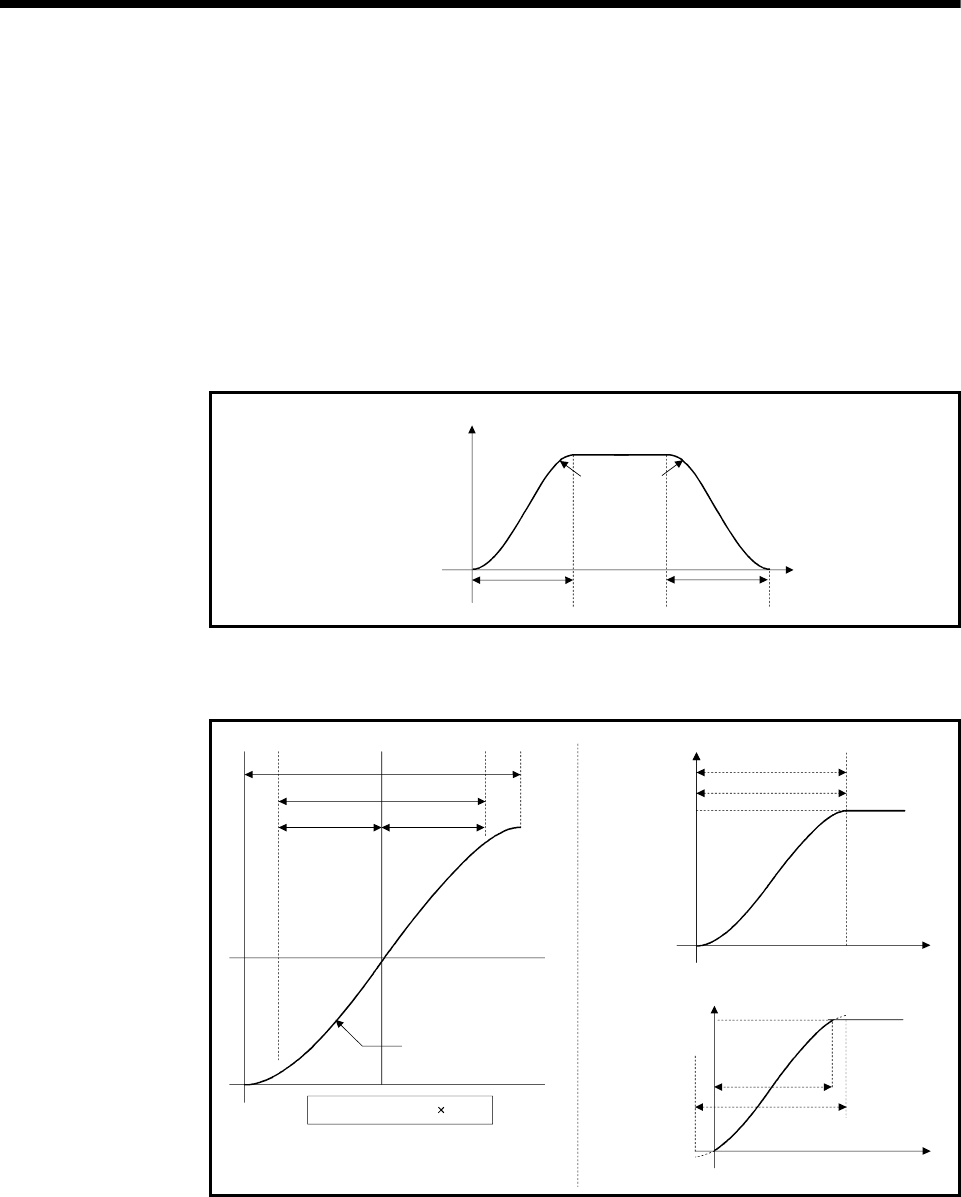

The graph for S-pattern processing is a sine curve as shown below.

Positioning speed

Sine curve

0

Acceleration

time

Deceleration

time

Time

t

V

As shown below, the S-curve ratio setting serves to select the part of the sine curve to

be used as the acceleration/deceleration curve.

A

B

B/2 B/2

Sine curve

S-curve ratio = B/A 100%

A

B

Positioning speed

B/A=1.0

V

t

Positioning speed

V

A

B

B/A=0.7

S-curve ratio is 100[%]

S-curve ratio is 70[%]

t

(Note) : When the G00, G01, G02, G03, G12, G13 or G32 including M-code is used,

S-curve ratio is ignored and control is executed as always 0[%].