3 - 15

3 MOTION DEDICATED PLC INSTRUCTION

(2) S(P).SVST instruction accepting and normal/abnormal completion can be

confirmed with the complete device(D1) or status display device(D2) at the

completion.

(a) Complete device

It is turned on by the END processing of scan which the instruction

completed, and turned off by the next END processing.

(b) Status display device at the completion

It is turned on/off according to the status of the instruction completion.

Normal completion : OFF

Abnormal completion : It is turned on by the END processing of scan

which the instruction completed, and turned off by

the next END processing.

[Setting range]

(1) Setting of the starting axis

The starting axis set as (S1) sets J + Axis No. in a character sequence " ".

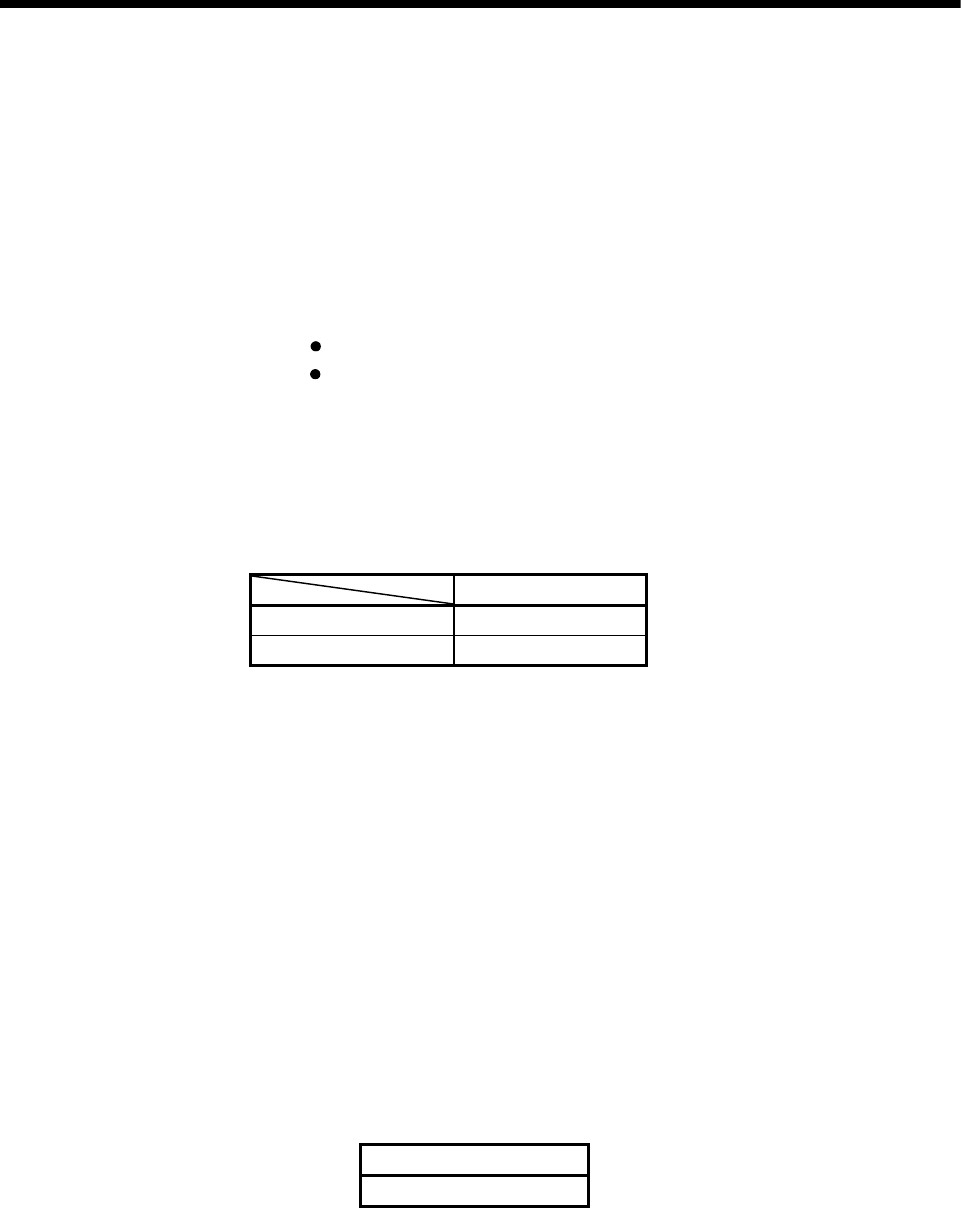

(S1) usable range

Q173HCPU 1 to 32

Q172HCPU 1 to 8

Up to 8 axes can be set. If multiple axes are set, it sets without dividing in a

space etc,.

The axis No. set in the system setting is used as the axis No. to start.

Refer to the "Q173HCPU/Q172HCPU Motion controller Programming Manual

(COMMON)" for system settings.

And, the axis No. to start does not need to be a order.

Example) When multiple axes (Axis1, Axis2, Axis10, Axis11)are set.

"J1J2J10J11"

(2) Setting of the Motion program (Axis designation program) No.

The usable range of axis designation program No. to set (S2) is checked in the

Motion CPU side.

(a) The control program No. is set

The specified axis designation program is started.

In this case, axis designation program is executed from the first block.

(S2) usable range

1 to 1024