6 - 80

6 MOTION PROGRAMS FOR POSITIONING CONTROL

6.13.14 G24 Cancel, cancel start

Code G24

Function Cancel, cancel start

The executing program is cancel and the specified start program

automatically starts.

This function is valid until cancel or cancel start function invalid (G23) is

executed.

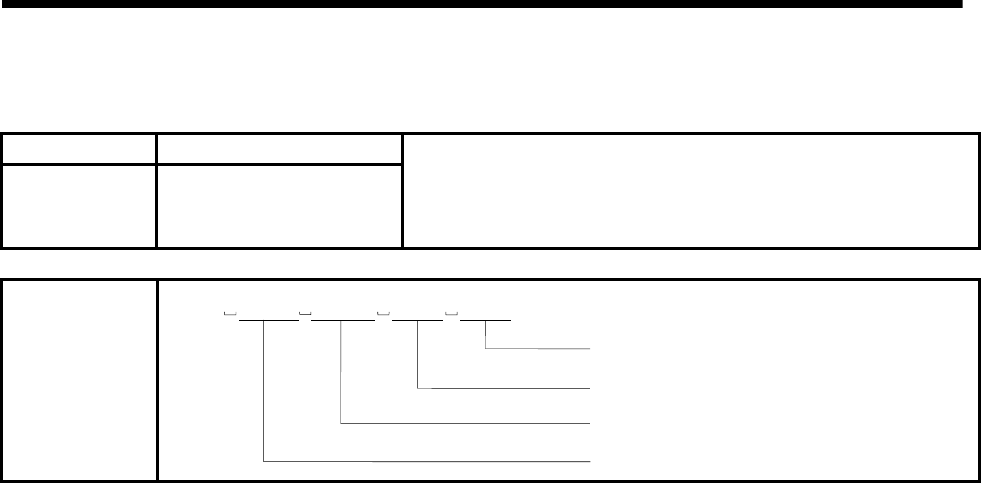

Format

2

Parameter block No.

(Indirect setting is possible)

Start program No.

(Indirect setting is possible)

4C NG

#

x

Cancel device

(X, Y, M, B, F)

Cancel designation

;PnA

X

Pn B

[Explanation]

(1) If the cancel device signal is turned ON during execution of this command, a

deceleration stop is made and the executing program is cancel (cancel function).

When the start program No. "Pn" has been set, after a deceleration stop by

turning ON the cancel signal, the specified program automatically starts (cancel

start function).

(2) This command cannot be used with the home position return (G28) instruction.

(3) In a waiting status for a restart (single block, M00, M01) during macro processing,

this command is made valid after completion of processing.

(4) If the cancel device turns ON during travel block switching, a cancel start is made

valid at the next travel block processing when there are no operating axes (no

high-speed oscillation axes).

(5) The device "X, Y, M, B and F" can be used for cancel. By assigning the input

signal for high-speed read function to the cancel device, response is made faster

than the input from the PLC CPU.

(6) The setting range of program No. "Pn" for a start is 1 to 1024.

(7) The parameter block of start program can be set with "PBn". The setting range of

parameter block No. "PBn" is 1 to 64. If the parameter block No. "PBn" is omitted

or it is set the outside of setting range, parameter block No. 1 is fixed.

(8) The program No. "Pn" and parameter block No. "PBn" set for a start can be set by

indirect setting with a variable, D, W, or # (2-word data).