APP - 20

A

PPENDICES

APPENDIX 1.3 Major errors

These errors occur by control command from the external input signal or Motion

program, and the error codes 1000 to 1999 are used.

Major errors include the positioning control start errors, positioning control errors

absolute position system errors and system errors.

(1) Positioning control start errors (1000 to 1099)

These errors are detected at the positioning control start.

The error codes, causes, processing and corrective actions are shown in Table

1.9.

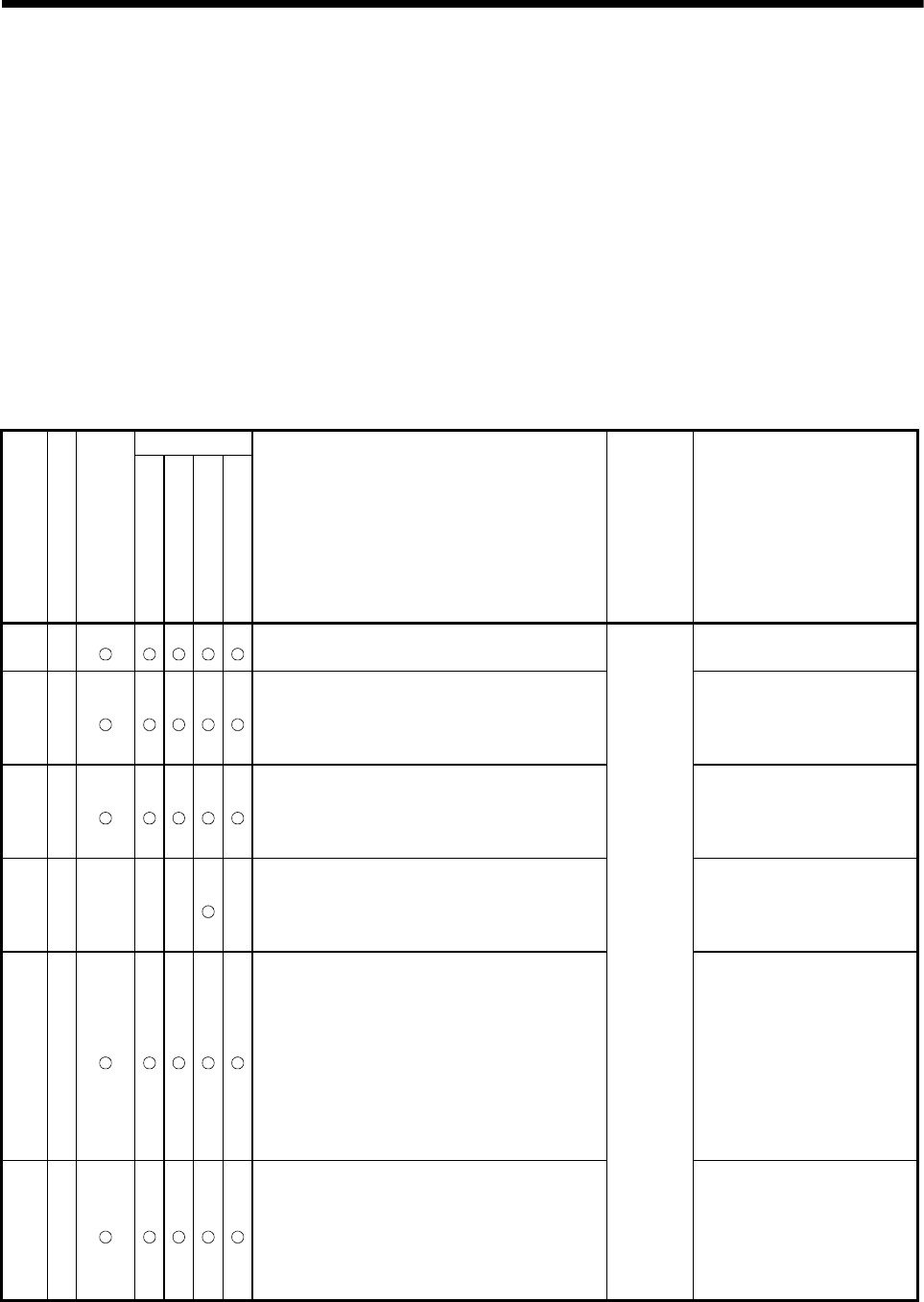

Table 1.9 Positioning control start error (1000 to 1099) list

Control mode

Error

code

Control program

Axis designation program

(positioning)

JOG

Manual pulse generator

Home position return

OSC

Error cause

Error

processing

Corrective action

1000

• The external STOP signal of the applicable axis

turned on.

• Turn the STOP signal off.

1001

• The external signal FLS (upper limit LS) turned off

at the forward direction (address increase

direction) start.

• Move in the reverse direction

by the JOG operation, etc.

and set within the external

limit range.

1002

• The external signal RLS (lower limit LS) turned off

at the reverse direction (address decrease

direction) start.

• Move in the forward direction

by the JOG operation, etc.

and set within the external

limit range.

1003

• The external DOG (proximity dog) signal turned

on at the home position return start of the

proximity dog type.

• Perform the home position

return after move to the

proximity dog ON by the JOG

operation, etc.

1004

• The applicable axis is not servo READY state.

(M2415+20n: OFF).

(1) The power supply of the servo amplifier is OFF.

(2) During initial processing after turning on the

servo amplifier.

(3) The servo amplifier is not installed.

(4) A servo error is occurred.

(5) Cable fault.

(6) Servo OFF command (M3215+20n) is ON.

• Wait until the servo READY

state (M2415+20n: ON).

1005

• The servo error detection signal of the applicable

axis (M2408+20n) turned on.

Positioning

control

does not

start.

• Eliminate the servo error, reset

the servo error detection

signal (M2408+20n) by the

servo error reset command

(M3208+20n), then start

operation.