6 - 42

6 MOTION PROGRAMS FOR POSITIONING CONTROL

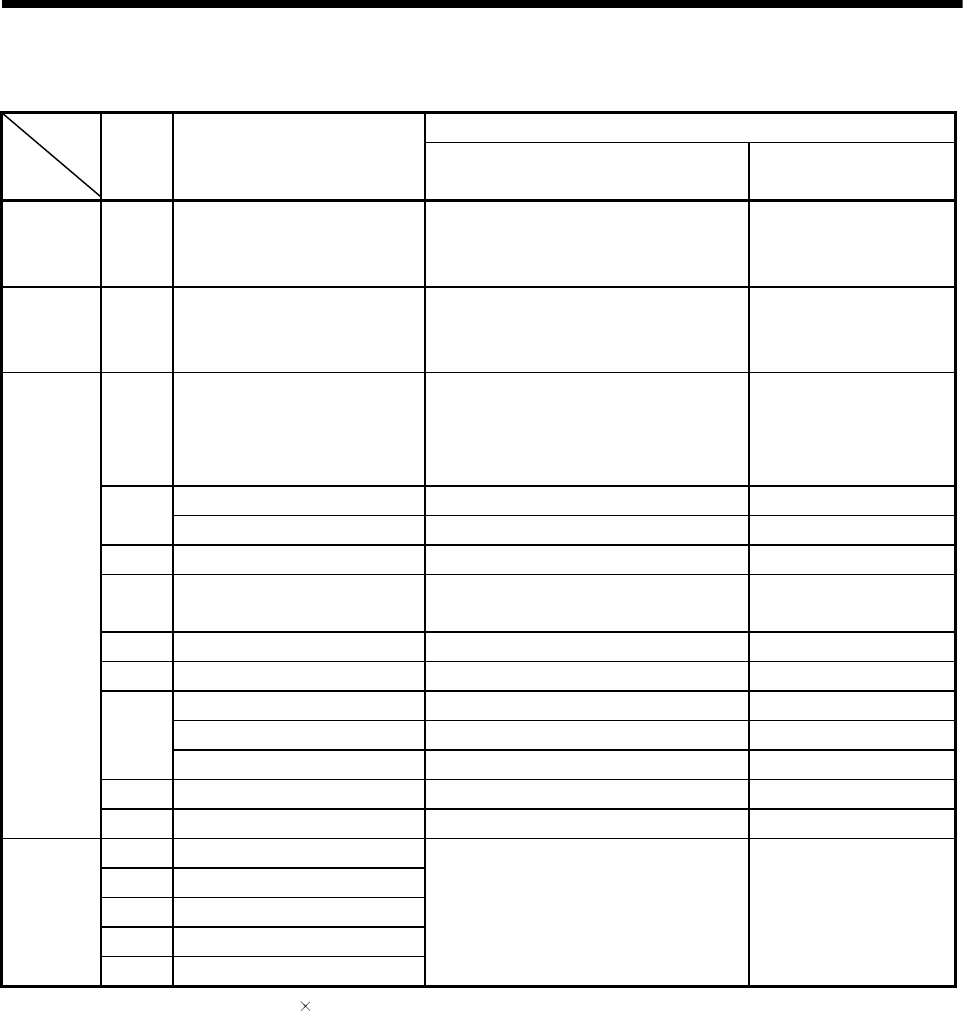

Table 6.2 Setting Range of Instruction Symbol List (Continued)

Setting range

Symbol Function

Motion program description

Indirect setting value by

variable

Address R

Radius of R point specified

circular arc

0 to 214748.3647 [mm]

0 to 21474.83647 [inch]

0 to 359.99999 [degree]

0 to 2147483647

0 to 35999999

Speed F

Interpolation feed combined

speed

0.01 to 6000000.00 [mm/min]

0.001 to 600000.000 [inch/min]

0.001 to 2147483.647 [degree/min]

(Note-1)

1 to 600000000

1 to 2147483647

G Preparatory function (G-code)

00, 01, 02, 03, 04, 09, 12, 13, 23, 24, 25,

26, 28, 30, 32, 43, 44, 49, 53, 54, 55, 56,

57, 58, 59, 61, 64, 90, 91, 92, 98, 99,

100, 101

–

Subprogram call sequence No. 1 to 9999 1 to 9999

H

Tool length offset data No. 1 to 20 1 to 20

L Subprogram repeat count 0 to 9999 0 to 9999

M

Auxiliary function

(M-code)

0 to 9999 0 to 9999

N Sequence No. 1 to 9999 –

O Motion program No. 1 to 1024 –

Dwell time 1 to 65535 1 to 65535

Start program No. 1 to 1024 1 to 1024

P

Subprogram call No. 1 to 1024 1 to 1024

PB Parameter block No. 1 to 16 1 to 16

Others

TL Torque limit value 1 to 1000 1 to 1000

+ Addition

- Subtraction

* Multiplication

/ Division

Operational

expression

MOD Remainder

-2147483648 to 2147483647

-2147483648 to

2147483647

(Note-1) : When the "speed control 10 multiplier setting for degree axis" set to "valid", the setting range is 0.01 to

21474836.47[degree/min].