5 - 20

5 PARAMETERS FOR POSITIONING CONTROL

5.4 Work Coordinate Data

(1) The work coordinate data is used to set the work coordinates and six different

work coordinates can be set (G54 to G59) for every axis. (Refer to Section 6.12 for

details.)

(2) The position is set with the offset from the mechanical coordinate system home

position for the work coordinate system. The offset setting value is the distance

from the mechanical coordinate system home position (0).

(3) The work coordinate data is set using the peripheral devices.

(4) The work coordinate data to be set are shown in Table 5.3.

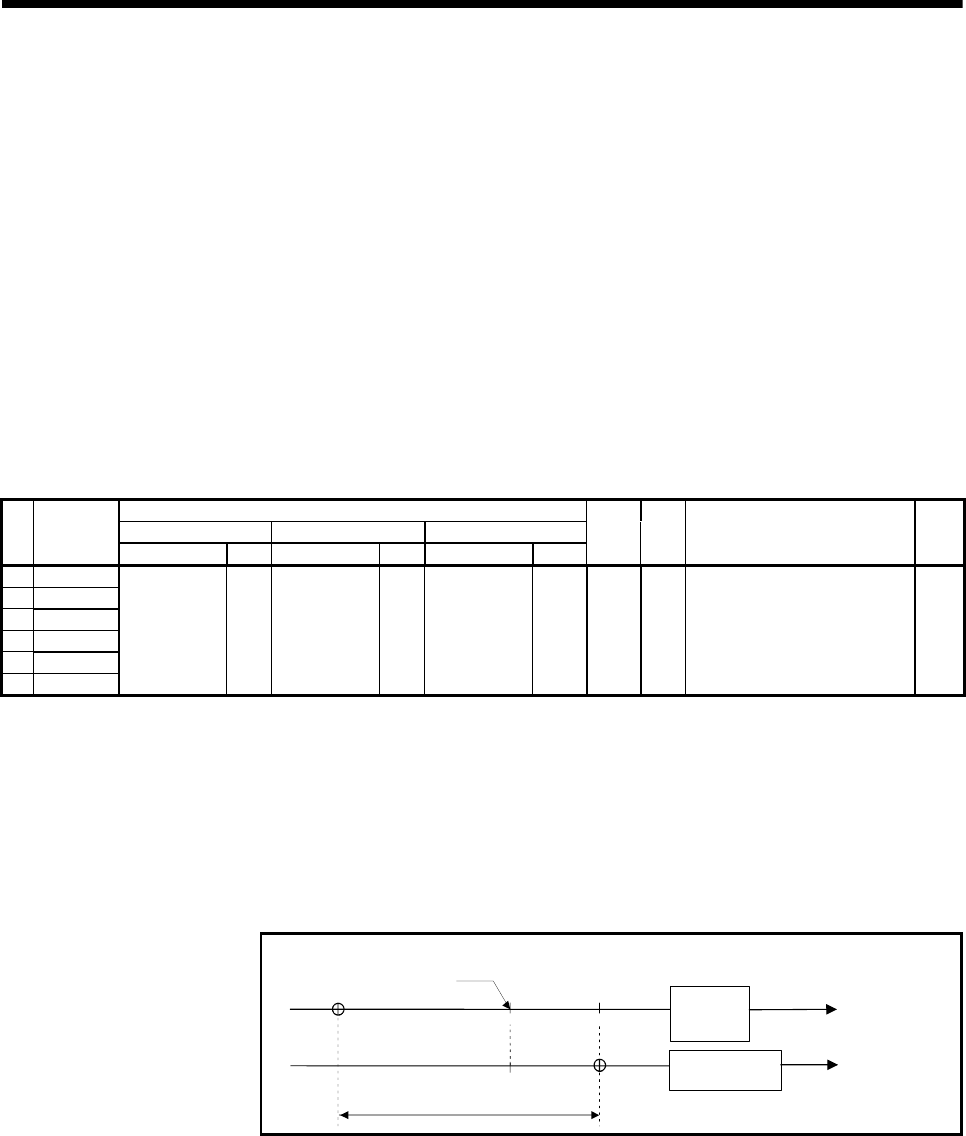

Table 5.3 Work Coordinate Data List

Setting range

mm inch degree

No. Item

Setting range Units Setting range Units Setting range Units

Initial

value

Units Remarks Section

1 G54

2 G55

3 G56

4 G57

5 G58

6 G59

-214748.3648

to

214748.3647

mm

-21474.83648

to

21474.83647

inch

-359.99999

to

359.99999

degree 0 mm

Set the work coordinate system 1 to 6.

6.12

(5) When a home position return is made based on the home position return setting

data, the mechanical coordinate system and work coordinate system are as

shown below.

[Example] The X-axis home position address of home position return data is set

to 200.00[mm] and the X-axis: G54 of the work coordinate data is set

to 300.00[mm] to make a home position return.

-

Home position return

complete point

200.00

+

Mechanical

coordinate

system

-

300.00

-100.00

G54=300.00 [mm]

+

0

Work coordinate

system (G54)

Monitor data

machine value

Current value

0

On completion of a home position return, the machine value is equal to

200.00[mm] and the current value is equal to -100.00[mm].

When the work coordinate data is set to 0, the current value is equal to the

machine value.