2 - 8

2 POSITIONING CONTROL BY THE MOTION CPU

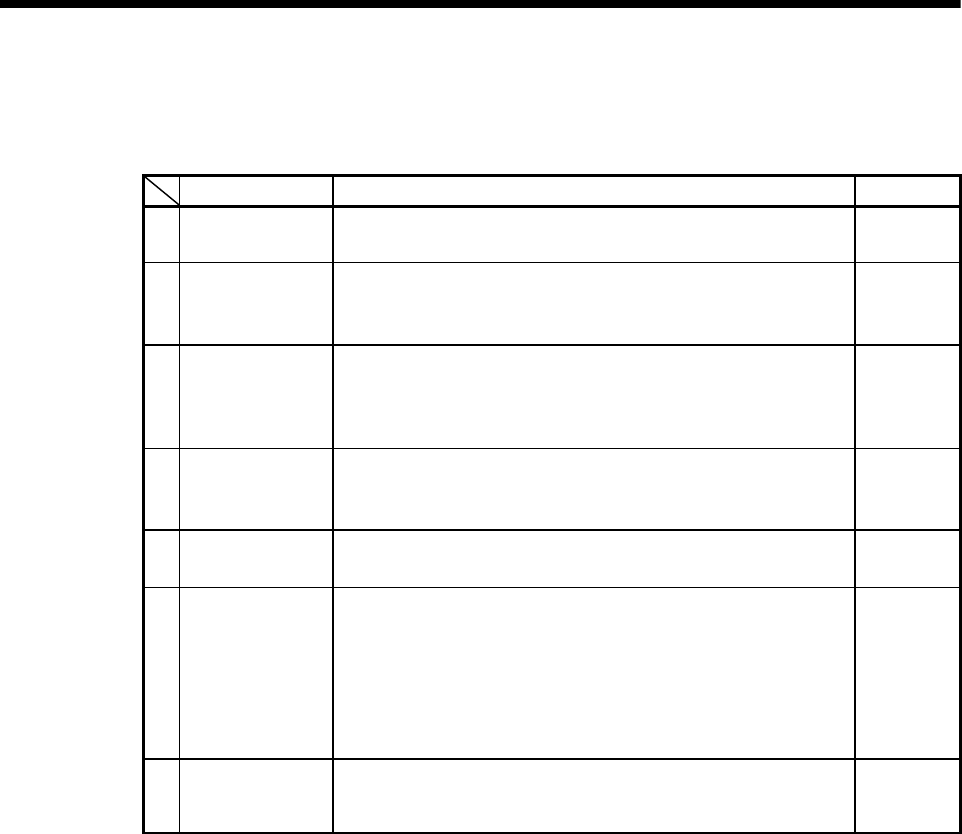

(1) Positioning control parameters

There are following seven types as positioning control parameters.

Parameter data can be set and corrected interactively using a peripheral device.

Item Description Reference

1 System settings

Multiple system settings, Motion modules and axis No., etc. are

set.

Section

5.1

2 Fixed parameters

Data by such as the mechanical system are set for every axis.

They are used for calculation of a command position at the

positioning control.

Section

5.2

3

Servo

parameters

Data by such as the servo amplifier and motor type with the

connected servomotor are set for every axis.

They are set to control the servomotors at the positioning

control.

(Note-1)

4

Home position

return data

Data such as the direction, method and speed of the home

position return used at the positioning control are set for every

axis.

Section

7.3.1

5

JOG operation

data

Data such as the JOG speed limit value and parameter block

No. used at the JOG operation are set for every axis.

Section

7.5.1

6 Parameter block

Data such as the acceleration/deceleration time and speed

control value at the positioning control are set up to 16

parameter blocks.

They are set with the servo program, JOG operation data and

home position return data, and it is used to change easily the

acceleration/deceleration processing (acceleration/deceleration

time and speed limit value) at the positioning control.

Section

5.3

7

Limit switch

output data

Output device, watch data, ON section, output enable/disable

bit and forced output bit used for the limit output function for

every limit output are set.

(Note-2)

(Note-1): Refer to Section 3.3 of the "Q173HCPU/Q172HCPU Motion controller Programming Manual

(COMMON)".

(Note-2): Refer to Section 4.1 of the "Q173HCPU/Q172HCPU Motion controller Programming Manual

(COMMON)".

(2) Motion program

The positioning control, JOG operation and manual pulse generator operation

are executed in the Motion program. The start request is performed using the

PLC program (S(P).SFCS/SVST instruction).

It comprises a Motion program No., G-code, M-code instruction and positioning

data.

Refer to Chapter 6 for details.

• Motion program No. ................

It is specified using the PLC program

(S(P).SFCS/SVST instruction).

• G-code, M-code instruction .....

It indicates the type of positioning control.

• Positioning data ......................

It is required to execute the G-code, M-code

instructions. The required data is fixed for

every G-code, M-code instruction.