E6581301

F-31

6

■ Torque bias function

Using this function, the load can be started

smoothly, by the motor produces enough torque

for load portion before the brake is released,

[Selection of external signals]

6.18 Acceleration/deceleration suspend function

H

HH

H :

Acceleration/deceleration

suspend function

H

HH

H :

Acceleration suspend frequency

H

HH

H : Acceleration suspend time

H

HH

H :

Deceleration suspend frequency

H

HH

H : Deceleration suspend time

• Function

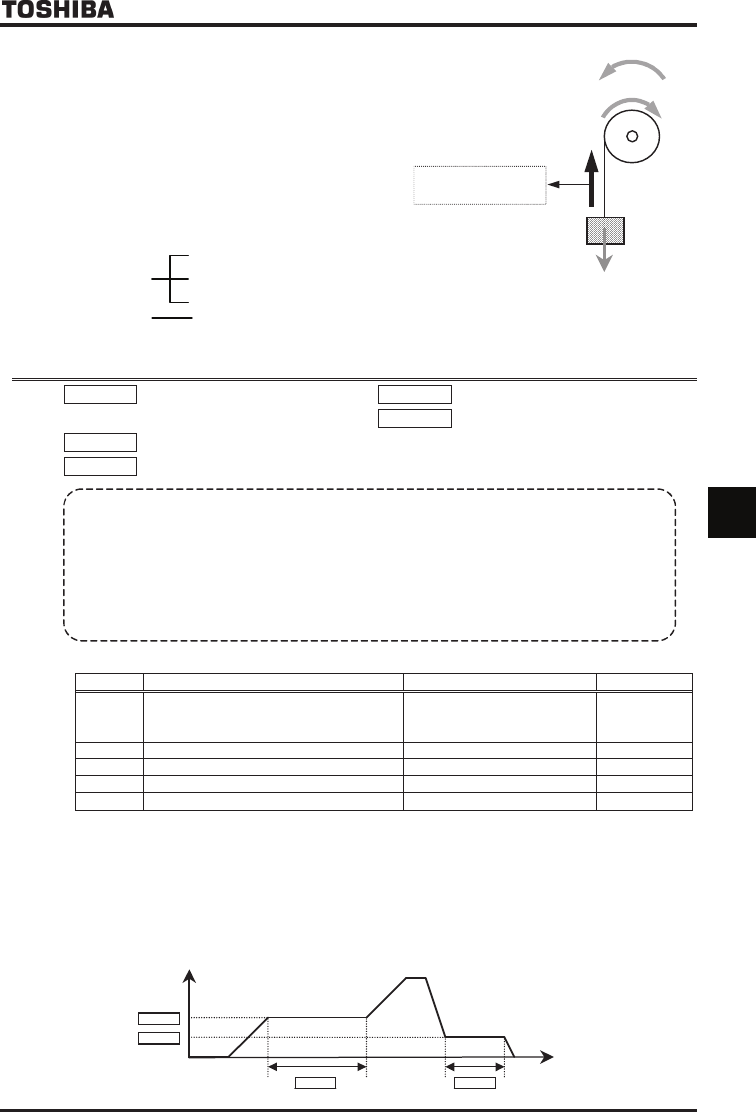

Using these parameters, acceleration or deceleration can be suspended to let the motor run at a constant

speed. There are two ways to suspend acceleration or deceleration: suspending it automatically by setting

the suspend frequency and time using parameters, and suspending it by means of a signal from an

external control device.

These parameters are useful in starting and stopping transfer equipment, textile machines (winders), and

so on.

[Parameter setting]

Title Function Adjustment range Setting value

H Acceleration/deceleration suspend function

:Disabled

:Parameter setting

:Terminal input

H Acceleration suspend frequency ~HJ Hz

H Acceleration suspend time ~ sec.

H Deceleration suspend frequency ~HJ Hz

H Deceleration suspend time ~ sec.

Note1: The acceleration suspend frequency (H) should not be set below the starting frequency (H).

Note2: The deceleration suspend frequency (H) should not be set below the stop frequency (H).

Note3: If the output frequency is lowered by a stall prevention function, the acceleration suspend function may be

activated.

1) To suspend acceleration or deceleration automatically

Set the desired frequency with H or H and the desired time with H or H, and then set

H to .

When the frequency set is reached, the motor stops accelerating or decelerating to rotate at a constant speed.

Output frequency [Hz]

H

Time [s]

H

H

H

H

RR/S4-CCA – 0~10V (0~250%)

RX-CCA – 0~±10V (-250~250%)

VI/II-CCA – 0~10V (0~250%)

VI/II-CCA – 4(0)~20mA (0~250%)

Voltage signals

Current signals

Additional torque

(fixed direction)

Reverse run

Forward run

Tension torque bias

as additional torque