E6581301

E-4

5

1) Increasing torque automatically according to the load

Set the automatic torque boost CW

CWCW

CW=

(automatic torque boost+auto-tuning 1)

Automatic torque boost CW= detects load current in all speed ranges and automatically adjusts voltage output

from inverter. This gives steady torque for stable runs.

Note 1: The same characteristic can be obtained by setting the V/f control mode selection parameter RV to

(automatic torque boost) and H (auto-tuning 1) to . Refer to Section 6.22.

Note 2: Setting CW to automatically programs RV to .

Note 3: If stable operation cannot be achieved with this setting, set the parameters XN (base frequency), XNX

(base-frequency voltage), H (rated capacity of motor), H (rated current of motor) and H

(rated number of revolutions of motor) as specified on the motor nameplate, and then set H to

and CW to again.

2)

When using vector control (increasing starting torque and high-precision operations)

Set the automatic torque boost CW

CWCW

CW=

(sensorless vector control 1+auto-tuning 1)

Setting automatic torque boost CW= (Sensorless vector control 1+auto-tuning 1) provides high starting torque

bringing out the maximum in motor characteristics from the low-speed range. This suppresses changes in motor

speed caused by fluctuations in load to provide high precision operation. This setting is most suitable for transfer

and lifting systems that are operated in speed control mode.

Note 1: The same characteristic can be obtained by setting the V/f control mode selection parameter RV to

(Sensorless vector control 1) and H (Auto-tuning 1) to . Refer to Section 6.22.

Note 2: Setting CW to automatically programs RV to .

Note 3: If stable operation cannot be achieved with this setting, set the parameters XN (base frequency), XNX

(base-frequency voltage), H (rated capacity of motor), H (rated current of motor) and H

(rated number of revolutions of motor) as specified on the motor nameplate, and then set H to

and CW to again.

■

■■

■ CW

CWCW

CW (automatic torque boost) and RV

RVRV

RV (V/f control mode selection)

Automatic torque boost is the parameter for setting V/f control mode selection (RV) and auto-tuning 1 (H)

together. That is why all parameters related to change automatically when CW is changed.

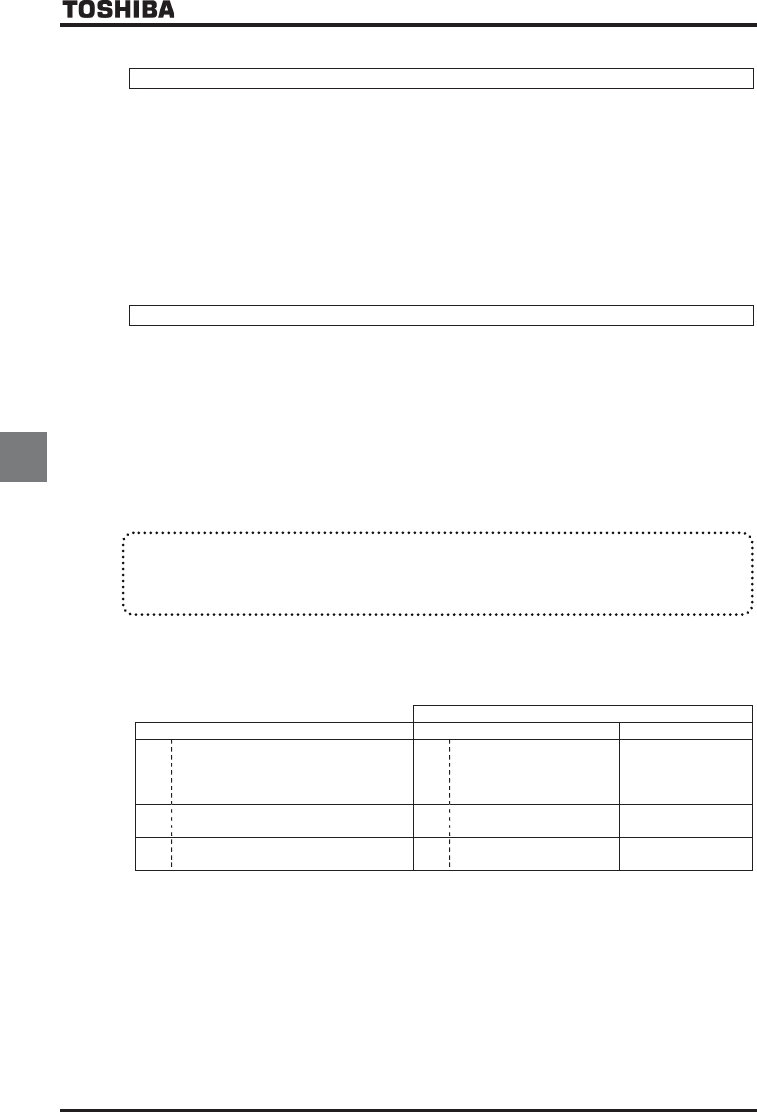

Automatically programmed parameters

CW RV H

Disabled (Always is displayed.) –

Check the programmed

value of RV. (If CW is not

changed, it becomes (V/f

constant).)

–

Automatic torque boost+auto-tuning 1

Automatic torque boost

: Executed ( after

execution)

Sensorless vector control 1+auto-tuning 1

Sensorless vector control 1

: Executed ( after

execution)

3) Increasing torque manually (V/f constant control)

The VF-AS1 inverter is set to this control mode by factory default.

This is the setting of constant torque characteristics that are suited for such things as conveyors. It can also be used

to manually increase starting torque.

To return to V/f constant control after changing the CW setting:

Set the V/f control mode selection parameter

RV

RVRV

RV

=

(constant torque characteristic).

Refer to Section 5.6.

Note: If you want to increase torque further, raise the setting value of manual torque boost XD.

How to set manual torque boost parameter XD Refer to Section 5.7.

If vector control cannot be programmed....

First read the precautions about vector control in 5.6, 9).

1) If the desired torque cannot be obtained Refer to 6.22 selection 3.

2) If auto-tuning error “GVP” appears Refer to 13.1 and 6.22 selection 3.