F-14

6.7 Operation frequency

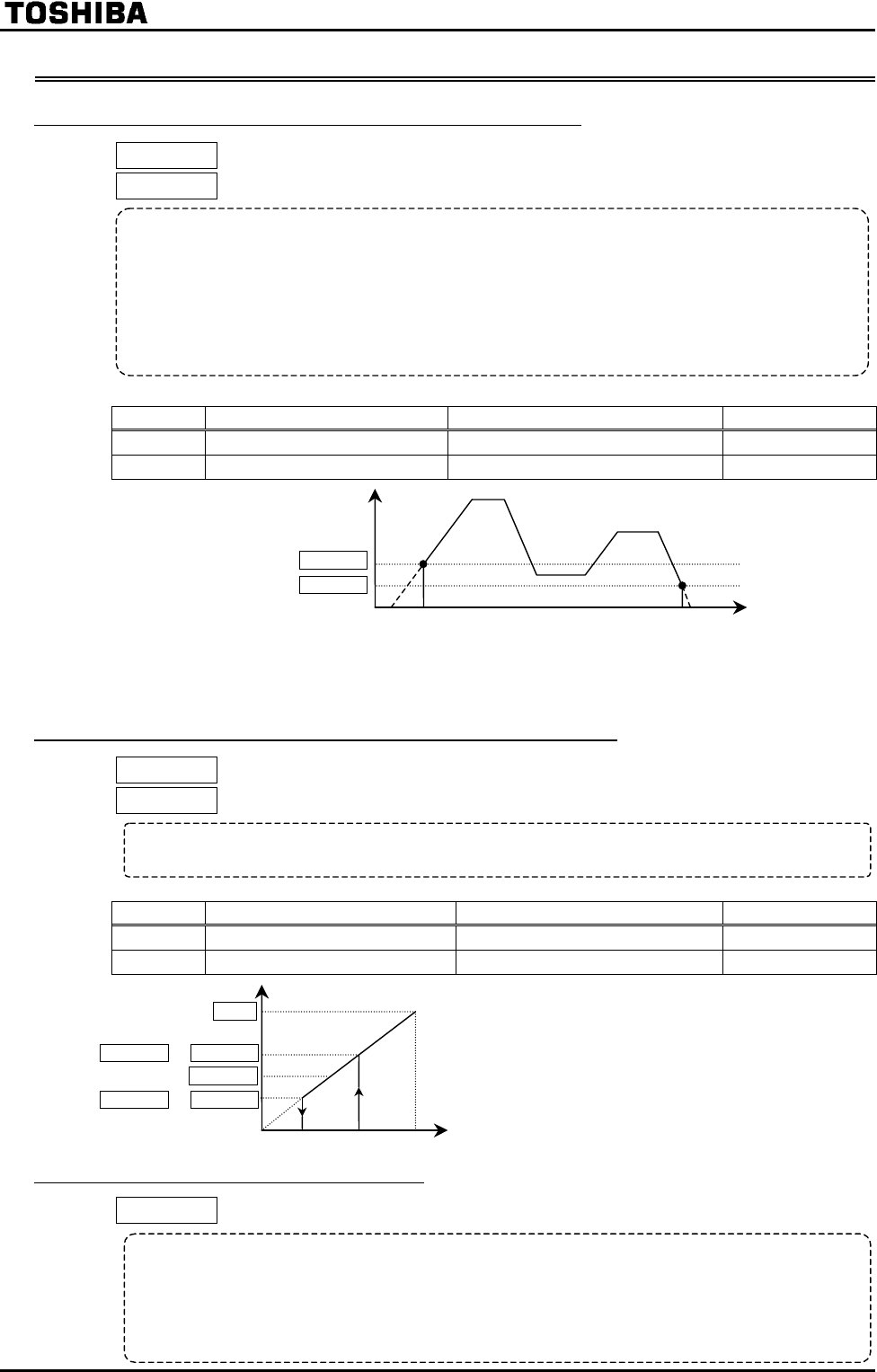

6.7.1 Start-up frequency and End frequency

Start-up frequency

Stop frequency

[Parameter setting]

Title Function Adjustment range Default setting

Start-up frequency

[Hz]

Stop frequency

[Hz]

Note) Set these parameters so that the start-up frequency is higher than the stop frequency .

If the -set frequency is lower than the -set frequency, the reference frequency

must be higher than the -set frequency to start the motor.

6.7.2 Operating by means of reference signals

Run frequency

Run frequency hysteresis

[Parameter setting]

Title Function Adjustment range Default setting

Run frequency

Run frequency hysteresis

[Hz]

6.7.3 0Hz dead band frequency

0Hz dead band frequency

Function

The frequency set with the parameter is put out immediately.

These parameters are used if the acceleration/deceleration time causes a delay in the response of

the starting torque. It is advisable to set these frequencies between 0.5 and 2 Hz (at a maximum

of 5 Hz). This setting reduces the slippage of motor below the rated value to prevent over-current.

If 0 speed torque is needed(pt = ,), set , at .

At startup: frequency set with is put out immediately.

At sto

p

: The out

p

ut fre

q

uenc

y

dro

p

s to 0 Hz immediatel

y

b

y

the fre

q

uenc

y

set with

.

Function

The start and stop of the motor can be controlled simply by giving frequency setting signals.

Start-up frequency

Stop frequency

Output frequency [Hz]

[s]

The motor starts to accelerate when the

frequency setting signal reaches point B, while

it starts to decelerate and stop when the

frequency setting signal falls below point A.

0 A B 100 Frequency reference [%]

Output frequency [Hz]

Function

In order to fixe the motor axis by the control with a sensor, you may set frequency

reference as 0[Hz] by the analog input etc.. But it may be set to 0[Hz] neither

by the drift nor offset. In such a case, this function sets frequency instructions to

0[Hz] certainly. When frequency reference is smaller than -set value,

fre

q

uenc

y

reference is set to 0

[

Hz

]

.