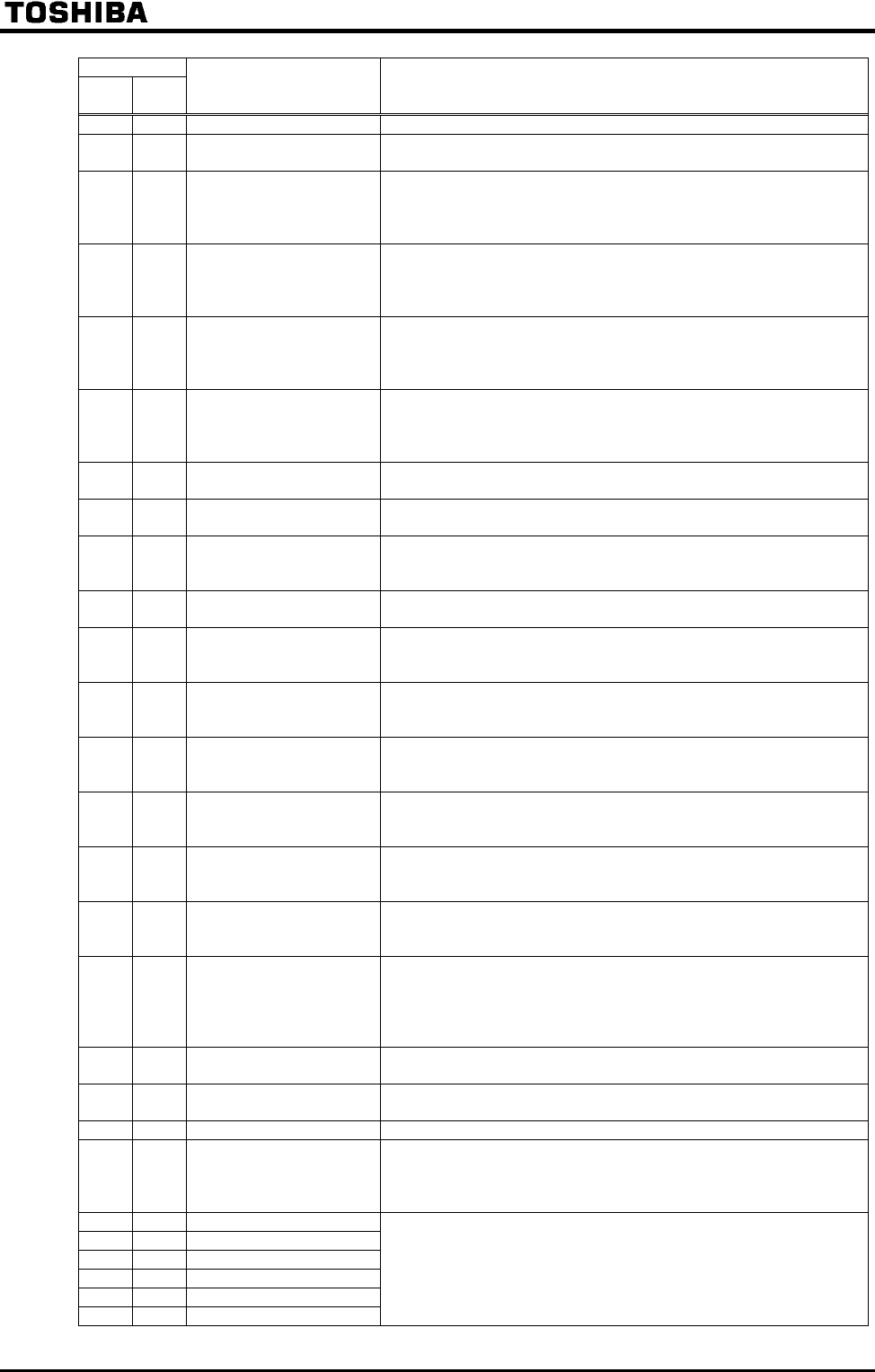

G-7

Parameter setting

Positive

logic

Negative

logic

Function Operation output specifications (in case of positive logic)

38 39 PID deviation limit "ON": PID deviation is in or set value.

40 41 Run/stop

"ON": Running frequency is output or DC injection breaking ()

is performed.

42 43 Serious failure

"ON": Serious failure(refer to technical terms on the previous page)

is detected.

"OFF": Inverter has recovered from serious failure. (Serious failure

has been reset)

44 45 Light failure

"ON": Light failure (refer to technical terms on the previous page) is

detected.

"OFF": Inverter has recovered from light failure. (Light failure has

been reset)

46 47

Commercial/INV

switching output #1

(for inverter operation

output)

Refer to 6.16.

48 49

Commercial/INV

switching output #2

(for commercial

operation output)

Refer to 6.16.

50 51 Cooling fan ON/OFF

"ON": Cooling fan is in operation.

"OFF": Cooling fan is off operation.

52 53 In Jog run

"ON": In jog run.

"OFF": In normal operation.

54 55

Panel operation/terminal

board operation

switching

"ON": In operation by terminal board.

"OFF": In operation by control panel.

56 57

Cumulative operation

time alarm

"ON": Cumulative operation time is beyond the set value.

"OFF": Cumulative operation time is less than the set value.

58 59

Abnormal communication

alarm #1

(caused by scanning)

"ON": Communication error caused by scanning has occurred.

"OFF": Communication error is cancelled (reset).

60 61

Forward/reverse

switching

"OFF": In forward operation.

"ON": In reverse operation.

(The last status is held while operation is suspended.)

62 63 Ready for operation #1

"ON": In operable status or operation can be started with frequency

command input as an operation switching answer-back.

"OFF": In inoperable status.

64 65 Ready for operation #2

"ON": In operable status or operation can be started with ST and

RUN signals and frequency command input

"OFF": In inoperable status.

66 67

Poor control power supply

() pre-alarm

"ON": Control circuit under-voltage is detected ().

(detection level; 200V class: approx. 145 VAC or lower,

400V class: approx. 290 VAC or lower)

68 69

System consistent

sequence

(BR: Brake release)

Output the braking signal according to the brake sequence.

70 71 In (pre-)alarm status

"ON": More than one of alarm, pre-alarm, under-voltage, low

current over-torque, poor control power supply, PID deviation

limit, abnormal frequency setting or torque limit have occurred

or detected.

"OFF": All the alarms above are cancelled.

72 73

Forward speed limit

(torque control)

"ON": Forward operation speed is set value or over.

"OFF": Forward operation speed is less than set value.

74 75

Reverse speed limit

(torque control)

"ON": Reverse operation speed is set value or over.

"OFF": Reverse operation speed is less than set value.

76 77 Inverter healthy output "ON" and "OFF" are alternately output at intervals of 1 second.

78 79

Abnormal communication

alarm #2 (caused by

RS485 logic or

message transmission)

"ON": Communication error caused by RS485 logic or message

transmission has occurred.

"OFF": Communication error is cancelled (reset).

80 81 Error code output #1

82 83 Error code output #2

84 85 Error code output #3

86 87 Error code output #4

88 89 Error code output #5

90 91 Error code output #6

Output the failure code in 6bits.