M-2

13. 2 Periodical inspection

Make periodical inspection at intervals of three or six months depending on operating conditions.

Danger

Mandatory

Complete the following steps before proceeding to periodical inspection.

1 Cut off power supply (turn off the inverter).

2 10 minutes or more after power cut off, check to see if the charge indicator lamp is turned

off.

3 Make sure that voltage in the DC main circuit (between PA and PC) is 45 V or lower by

use of a tester capable of measuring high DC tension (800 V DC or more).

If the above-mentioned steps are skipped before inspection, it may cause an electric shock.

Prohibited

Don't replace any component part.

Replacement of a component part by user may cause electric shock, fire or injury. Ask the

dealer for replacement of part.

Points of inspection

1. Check to see if there is some wire terminal screw getting loose. If any, tighten it with a

screwdriver.

2. Make sure by eye-check that there is neither poorly clinched part nor overheated clinch in

wire terminals.

3. Check to see by eyes if there is any damage on wire or cable.

4. Clean up dust and soil. Absorb dust by a vacuum cleaner. Carefully clean the vents, printed

circuit boards and so on. If those parts get dusty, it may cause an unexpected accident.

Keep them clean always.

5. If the inverter won't be used for a long time, turn it on once every another year to check

operation. Furthermore, disconnect the motor and supply power to the inverter for five hours

or more. For turning on the inverter very seldom, it is recommended not to supply

commercial mains power directly to the inverter but to use a step-up transformer to supply

power at a low voltage first and to raise the voltage gradually.

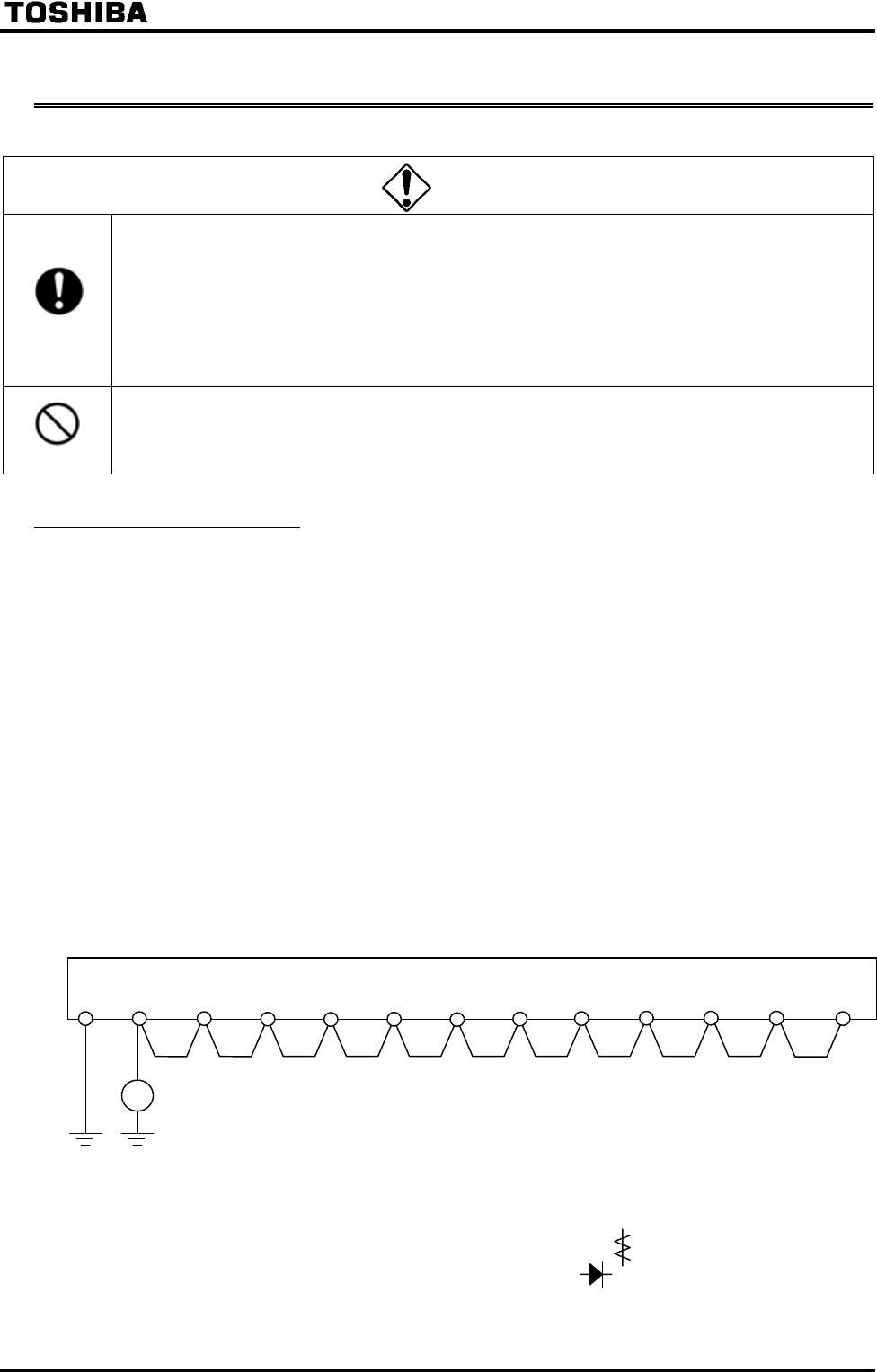

6. If insulation test is needed, conduct it for the main circuit terminal board and control power

terminal board using a 500 V insulation resistance tester only. Don't conduct insulation test

for control terminals and circuit terminals on printed circuit boards except of the main circuit.

For insulation test of motor, disconnect output terminals of U, V and W and conduct test for

the motor only. If insulation resistance is below 10 M , make a service call.

Note: Disconnect all cables from terminals of the main circuit terminal board, and conduct

insulation test with the inverter only.

7. Make no pressure test, because it may cause damage to internal parts.

8. Voltage and temperature check

Recommended voltmeter:

For input side: Moving-iron type voltmeter

For output side: Rectifier type voltmeter

If ambient temperature is measured at start time, during operation, and at stop time usually,

recorded data will be helpful to find sign of failure or malfunction.

500 V insulation

resistance

tester

/ / / / / /