A-10

A load, e.g., a reciprocating load, which requires a frequent change in the rotating speed

In this case, if the inverter is in vector control mode, adjust the response time (setting of

moment of inertia) or switch to V/f control mode to stabilize the operation.

If it is operated in vector control mode, only a motor whose capacity is same as inverter

standard or 1 rank lower is applied.

If it is operated in V/F (other than vector control), the rotating of motor can be unstable in

combination with 3 or more ranks smaller motor.

<Stabilizing operation>

Lower the setting value of F300(PWM carrier frequency). (It causes much magnetic

noise of motor, but it is not abnormal.)

In the case that it is still unstable even if the carrier frequency is lowered to 2.2kHz at

( ), set the setting value of F489(

Dead time compensation) to 1 (Disabled) .

Braking of a motor after power shutoff

If the power is shut off while the motor is still rotating, the motor keeps rotating (or coasting) for

a while before it comes to a complete stop. If you wish to stop it soon after turning off the

power, equip the motor with an auxiliary braking system. There are several types of braking

systems available, for example, mechanical and electrical types. Select a braking system

which matches your system.

Load producing negative torque

When the inverter is combined with a load producing negative torque, the over-voltage or

over-current protective function of the inverter sometimes works and causes the motor to trip.

In this case, it is necessary to install a dynamic braking resistor, etc., suitable for the load.

Motor with a braking system

When a brake-equipped motor is connected directly with the inverter, the brake cannot be

released at start-up because of an insufficient voltage. To avoid this, connect the brake cables

separately from the motor main cables.

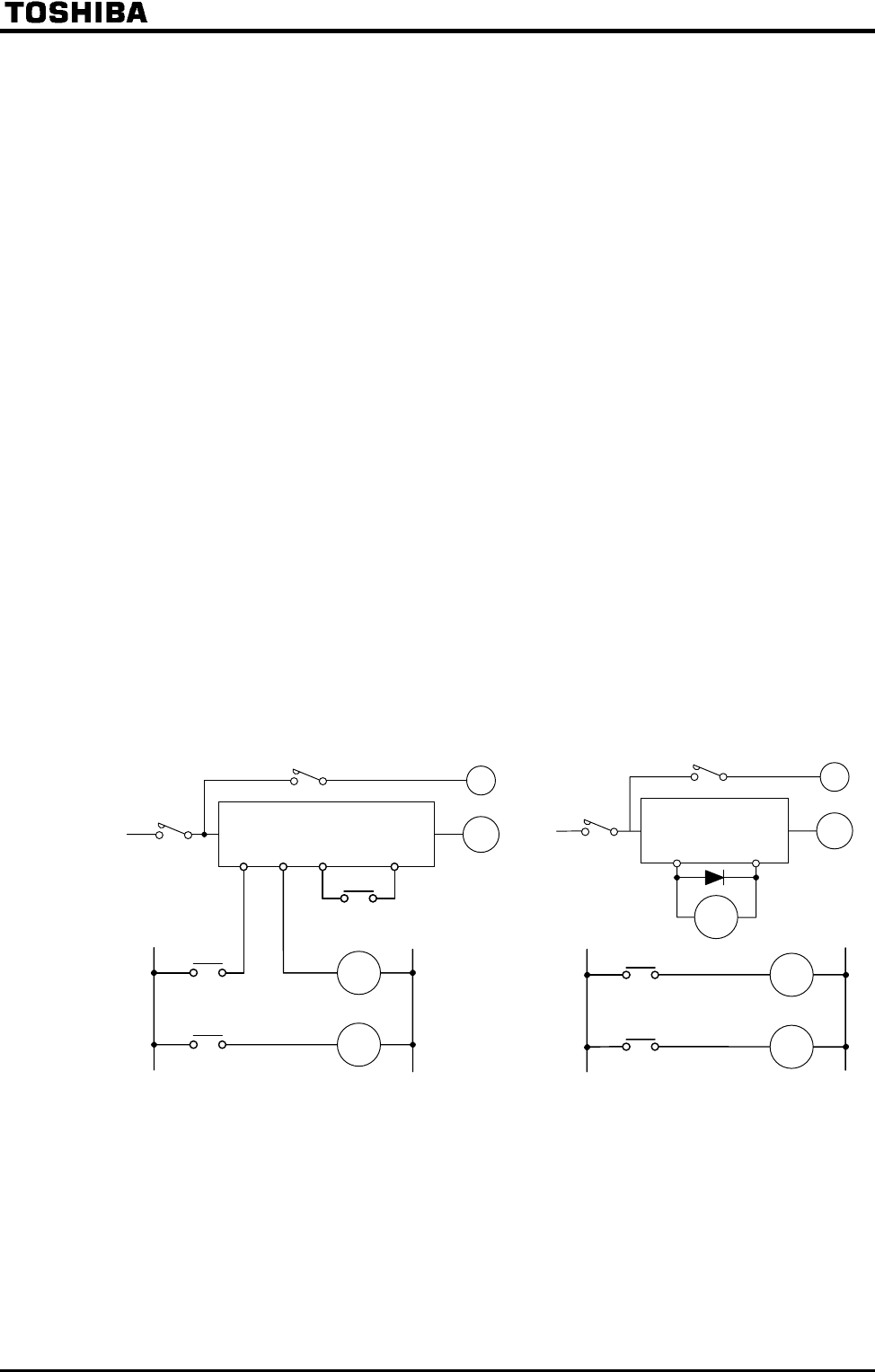

(Non-exciting brake) (Non-exciting brake)

Circuit configuration 1 Circuit configuration 2

In circuit configuration 1, the brake is turned on and off by means of MC2 and MC3. If the

circuit is configured differently, the motor can trip because of a locked rotor current produced

during braking.

In circuit configuration 2, the brake is turned on and off by means of a low-speed signal

OUT1. However, for certain applications, e.g., elevator applications, it is recommended to

use a low-speed detection signal (function of terminal OUT1) to turn on and off the motor.

Contact your Toshiba dealer before designing a system.

MC1

MC3

MC1

MC3

Three-phase

power supply

MC2

B

IM

FLB FLC ST CC

MC2

MC3

MC1

Three-phase

power supply

LOW

MC3

MC2

B

IM

LOW

OUT1

P24

MC3

MC2