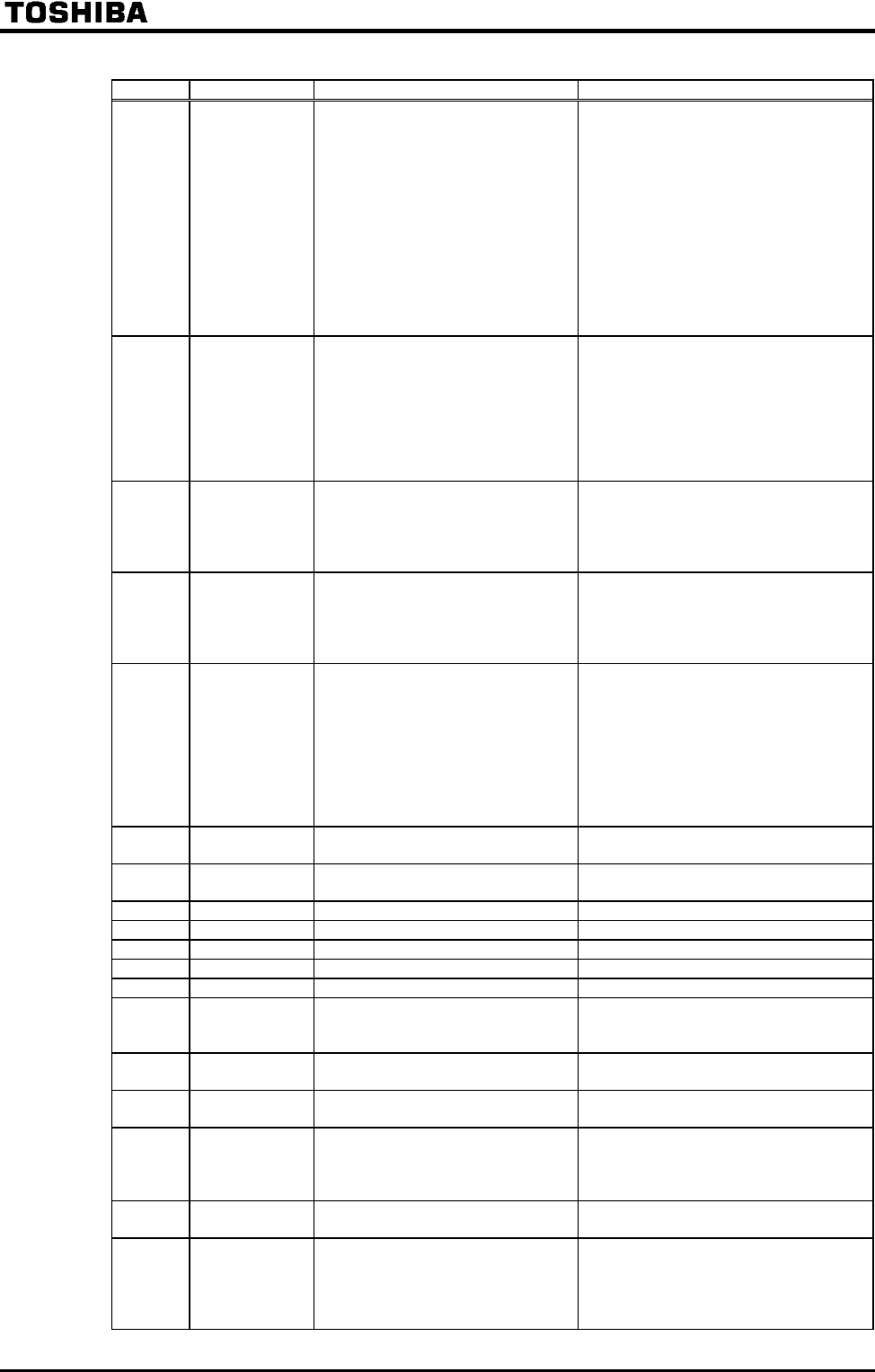

L-2

(Continued from the preceding page)

Indication

Contents Expected causes

Countermeasures

Over-voltage

during fixed

speed

Input voltage abnormally varied.

1 Power capacity is 500 kVA or

more.

2 Power-factor improving

capacitor was turned on/off.

3 Some unit using thyrister is

connected with the same

power supply line.

Motor falls into regeneration status

because it is rotated fast

exceeding inverter's output

frequency by power of loaded

side.

Try to insert input reactor.

Install dynamic braking resistor.

Inverter

overloaded

Rapid acceleration is operated.

DC breaking rate is too high.

V/f parameter is improperly set.

Running motor is started during

momentary power failure status

or so.

Load is too heavy.

Extend acceleration time #1 .

Decrease values of DC injection

braking current and DC

injection braking time .

Check V/f parameter.

Use (Auto-restart) and

(

Regenerative power ride-through control

).

Raise rating of the inverter.

Motor

overloaded

V/f parameter is improperly set.

Motor is locked.

Continuous operation in low

speed range.

Motor is operated with overload.

Check V/f parameter.

Check loading unit.

Reset properly to motor's

overload reduction start-up

frequency.

Dynamic braking

resistor overload

Rapid deceleration is operated.

Dynamic braking rate is too high.

Set over-voltage limit operation

revel parameter too small.

Extend deceleration time #1 .

Increase capacity (wattage) of

dynamic braking resistor and reset

the PBR capacity parameter .

Increase the setting value of .

Overheat

Cooling fan is not actuated.

Ambient temperature is too high.

Vent of cooling fan is shut.

Some heat generating matter is

located nearby.

Internal thermistor of unit is

disconnected.

After cooling down inverter, reset it

from failure and try to restart it.

If cooling fan does not work in

operation, it needs replacement.

Secure spaces in the periphery of the

inverter.

Don't locate any heat generating thing

near the inverter.

Make a service call.

Emergency

stop

Inverter is stopped by panel operation

during automatic or remote operation.

Reset the inverter.

EEPROM error

Error occurs during writing data. Again turn on the inverter. If it is not

reset, make a service call.

Initial read-error

Something abnormal in internal data.

Make a service call.

Initial read-error

Something abnormal in internal data.

Make a service call.

Main RAM fault

Something abnormal in control RAM.

Make a service call.

Main ROM fault

Something abnormal in control

ROM.

Make a service call.

CPU

fault

Something abnormal in control CPU.

Make a service call.

Interruption

communication

fault

Something abnormal occurred

during communication operation.

Check communication units and their

connections.

Gate array

fault

Main gate array is abnormal. Make a service call.

Output current

detector error

Main output current detector is

abnormal.

Make a service call.

Optional unit

fault

Something abnormal occurred in

some optional unit (including

abnormal communication [optional

add-on cassettes]).

Check connection of optional

board(s).

Refer to instructions of options

concerned.

Flush memory

fault

Something abnormal in flush

memory.

Make a service call.

(*1)

low-current

operation

Output current declined to the

low-current detection level during

operation.

Check to see if low-current detection

level is set properly to the system or

not ().

If low-current detection level is

properly set, make a service call.

(Continued on the following page)