235

Special operation and speed control

4

PARAMETERS

4.19 Special operation and speed control

4.19.1 PID control (Speed control) (Pr.127 to Pr.134)

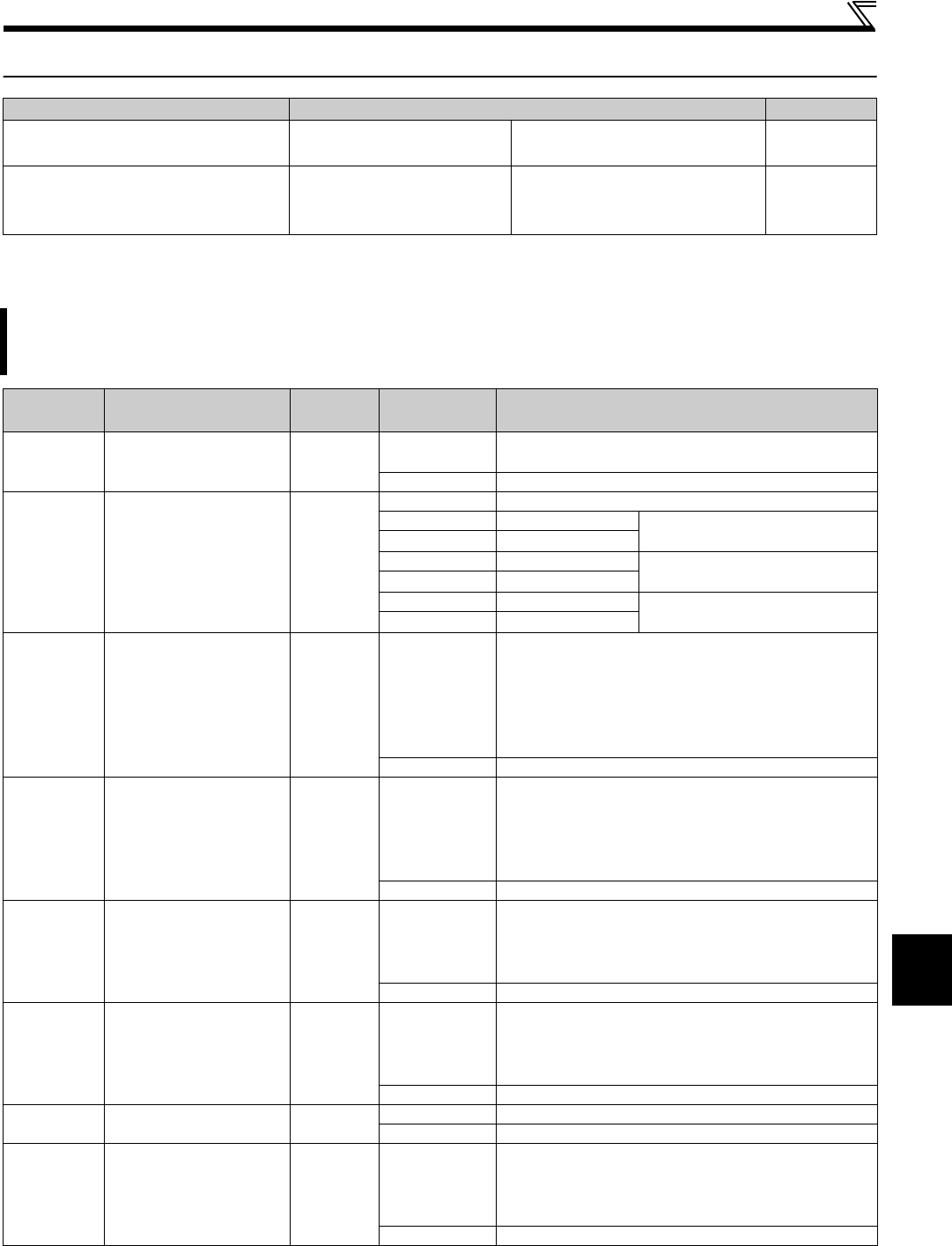

Purpose Parameter to set Refer to page

To perform process control such as

pump and air volume

PID control Pr.127 to Pr.134

235

To avoid overvoltage alarm due to

regeneration by automatic

adjustment of output speed

Regeneration avoidance

function

Pr.882, Pr.883, Pr.885, Pr.886

242

The drive unit can be used to exercise process control, e.g. flow rate, air volume or pressure.

The terminal 2 input signal or parameter setting is used as a set point and the terminal 4 input signal used as a

feedback value to constitute a feedback system for PID control.

Parameter

number

Name

Initial

value

Setting

range

Description

127

PID control automatic

switchover speed

9999

0 to 4800r/min

Speed at which the control is automatically changed to PID

control.

9999 Without PID automatic switchover function

128 PID action selection

0

0 PID action is not performed

20 PID reverse action Measured value (terminal 4)

Set value (terminal 2 or Pr.133)

21 PID forward action

50 PID reverse action Deviation value signal input (CC-Link

communication)

51 PID forward action

60 PID reverse action Measured value, set point input (CC-

Link communication)

61 PID forward action

129 PID proportional band

100%

0.1 to 1000%

If the proportional band is narrow (parameter setting is

small), the manipulated variable varies greatly with a slight

change of the measured value. Hence, as the proportional

band narrows, the response sensitivity (gain) improves but

the stability deteriorates, e.g. hunting occurs. Gain Kp= 1/

proportional band

9999 No proportional control

130 PID integral time

1s

0.1 to 3600s

When deviation step is input, time (Ti) is the time required

for integral (I) action to provide the same manipulated

variable as the proportional (P) action. As the integral time

decreases, the set point is reached earlier but hunting

occurs more easily.

9999 No integral control.

131 PID upper limit

9999

0 to 100%

Maximum value

If the feedback value exceeds the setting, the FUP signal is

output. The maximum input (20mA/5V/10V) of the measured

value (terminal 4) is equivalent to 100%.

9999 No function

132 PID lower limit

9999

0 to 100%

Minimum frequency

If the measured value falls below the setting range, the FDN

signal is output. The maximum input (20mA/5V/10V) of the

measured value (terminal 4) is equivalent to 100%.

9999 No function

133 PID action set point

9999

0 to 100% Used to set the set point for PID control.

9999 Terminal 2 input is the set point.

134 PID differential time

9999

0 to 100%

For deviation ramp input, time (Td) required for providing

only the manipulated variable for the proportional (P) action.

As the differential time increases, greater response is made

to a deviation change.

9999 No differential control.

The above parameters can be set when Pr.160 Extended function display selection = "0". (Refer to page 182)

Pr.129, Pr.130, Pr.133 and Pr.134 can be set during operation. These can also be set independently of the operation mode.

When a value exceeding 3000 r/min is set, the rotation speed will be limited at 3000 r/min.

Also, when an S-PM geared motor is used, the maximum setting value differs depending on the drive unit capacity. (0.2 to 2.2K: 12000 r/min, 3.7K: 8000 r/

min)