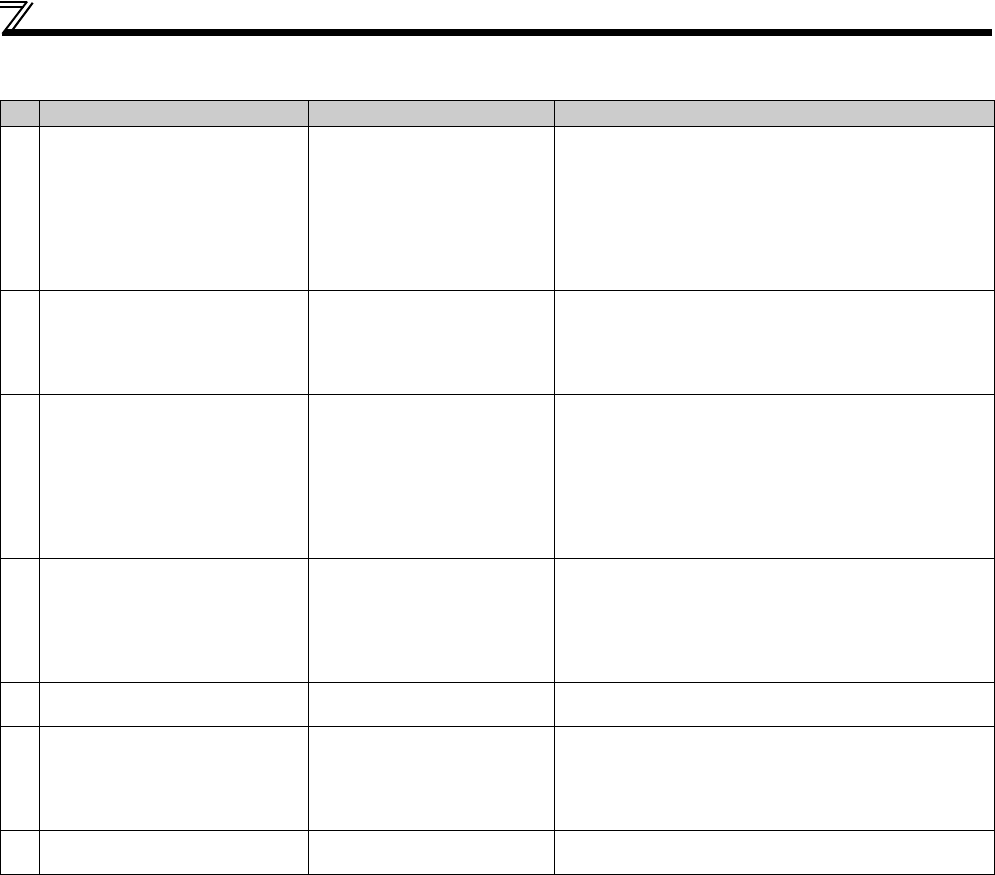

82

Speed control

(4) Troubleshooting

Condition Possible cause Countermeasure

1

Motor does not run at the correct

speed.

(Command speed and actual speed

differ.)

(1) Speed command from the

controller is different from

the actual speed.

The speed command is

affected by noise.

(2) The command speed and the

speed recognized by the

drive unit are different.

(1) Check that the speed command sent from the controller

is correct.

(Take EMC measures.)

(2) Adjust bias and gain (Pr.125, Pr.126, C2 to C4) of the

speed command again.

2

The speed does not accelerate to

the command speed.

(1) Torque shortage

The torque limit is activated.

(2) Only P (proportion) control is

performed.

(1) -1 Raise the torque lilmit level. (Refer to page 111)

(1) -2 Capacity shortage

(2) Speed deviation occurs under P (proportional) control

when the load is heavy. Select PI control.

3 Motor speed fluctuates.

(1) Speed command varies.

(2) Torque shortage

(3) Speed control gain is not

suitable for the machine.

(Resonance occurs.)

(1) -1 Check that the speed command sent from the

controller is correct. (Take EMC measures.)

(2) Raise the torque lilmit level. (Refer to page 111)

(3) Adjust Pr.820 and Pr.821 (Refer to page 80)

4

Hunting (vibration or acoustic

noise) occurs in the motor or the

machine.

(1) Speed control gain is too

high.

(2) Motor wiring is incorrect.

(3) Mechanical resonance

occurs.

(1) Set Pr.820 lower and Pr.821 higher.

(2) Check the wiring.

(3) Set and adjust the notch filter (Pr.862, Pr.863, and Pr.871).

5

Acceleration/deceleration time is

different from the setting.

(1) Torque shortage

(2) Load inertia is too high.

(1) Raise the torque lilmit level. (Refer to page 111)

(2) Set acceleration/deceleration time suitable for the load.

6 Machine movement is unstable.

(1) Speed control gain is not

suitable for the machine.

(2) Response is slow because of

the drive unit's acceleration/

deceleration time setting.

(1) Adjust Pr.820 and Pr.821 (Refer to page 80)

(2) Set the optimum acceleration/deceleration time.

7

Rotation ripple occurs during the

low-speed operation.

Speed control gain is too low. Raise Pr.820.