282

Check first when you have a trouble

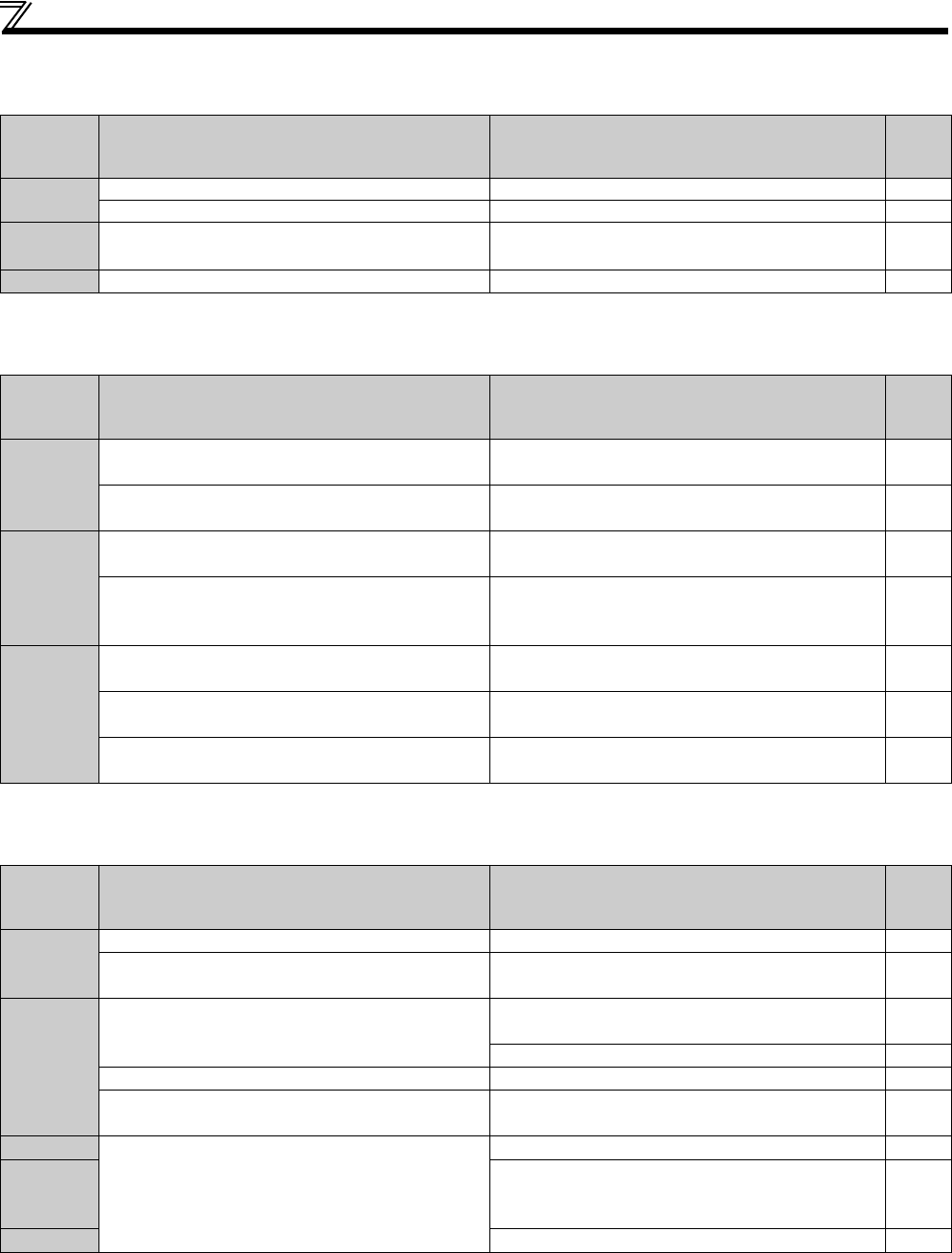

5.5.3 Motor generates heat abnormally

5.5.4 Motor rotates in the opposite direction

5.5.5 Speed greatly differs from the setting

Check

Points

Possible Cause Countermeasures

Refer

to

page

Motor

The required space is not provided around the motor. Improve the environment around the motor.

The mounting flange is small. Use a bigger flange.

Main

Circuit

The drive unit output voltage (U, V, W) are unbalanced.

Check the output voltage of the drive unit.

Check the insulation of the motor.

289

Motor current is large. Refer to "5.5.10 Motor current is too large" 284

Check

Points

Possible Cause Countermeasures

Refer

to

page

Main

Circuit

Phase sequence of output terminals U, V and W is

incorrect.

Connect phase sequence of the output cables (terminal

U, V, W) to the motor correctly

15

The rotation direction of the output shaft is changed by

the reduction gear.

Check the rotation direction of the motor's output shaft. 15

Input

Signal

The start signals (forward rotation, reverse rotation) are

connected improperly.

Check the wiring. (STF: forward rotation, STR: reverse

rotation)

18

Adjustment by the rotation speed is improper during the

reversible operation with Pr.73 Analog input selection

setting.

Check the setting of Pr.125, Pr.126, C2 to C7. 173

Parameter

Setting

Pr.40 RUN key rotation direction selection setting is

incorrect.

Check the Pr.40 setting. 255

Under position control, the sign of the position

command is incorrect.

Check the sign setting of positioning sub-function in

Pr.525 to Pr.531.

95

Under position control, the Pr.463 Position control rotation

direction selection setting is incorrect.

Check the Pr.463 setting. 92

Check

Points

Possible Cause Countermeasures

Refer

to

page

Input

Signal

Speed setting signal is incorrectly input. Measure the input signal level.

The input signal lines are affected by external EMI.

Take countermeasures against EMI such as using

shielded wires for input signal lines.

36

Parameter

Setting

Pr.1, Pr.2, calibration parameter C2 to C7 settings are

improper.

Check the settings of Pr.1 Maximum setting, Pr.2 Minimum

setting.

115

Check the calibration parameter C2 to C7 settings. 173

Pr.31 to Pr.36 (speed jump) settings are improper. Narrow down the range of speed jump. 116

Under position control, the maximum speed setting is

incorrect in Pr.4 to Pr.6, and Pr.24 to Pr.27.

Check the maximum speed setting in Pr.4 to Pr.6, and

Pr.24 to Pr.27.

95

Load

Torque limit function is activated due to a heavy load.

Reduce the load weight.

Parameter

Setting

Set Pr.22 Torque limit level higher according to the load.

(Setting Pr.22 too large may result in frequent

overcurrent trip (E.OC).)

111

Motor

Check the capacities of the drive unit and the motor.