273

5

TROUBLESHOOTING

Causes and corrective actions

Resetting the drive unit initializes the internal thermal integrated data of the electronic thermal relay function.

Operation panel

indication

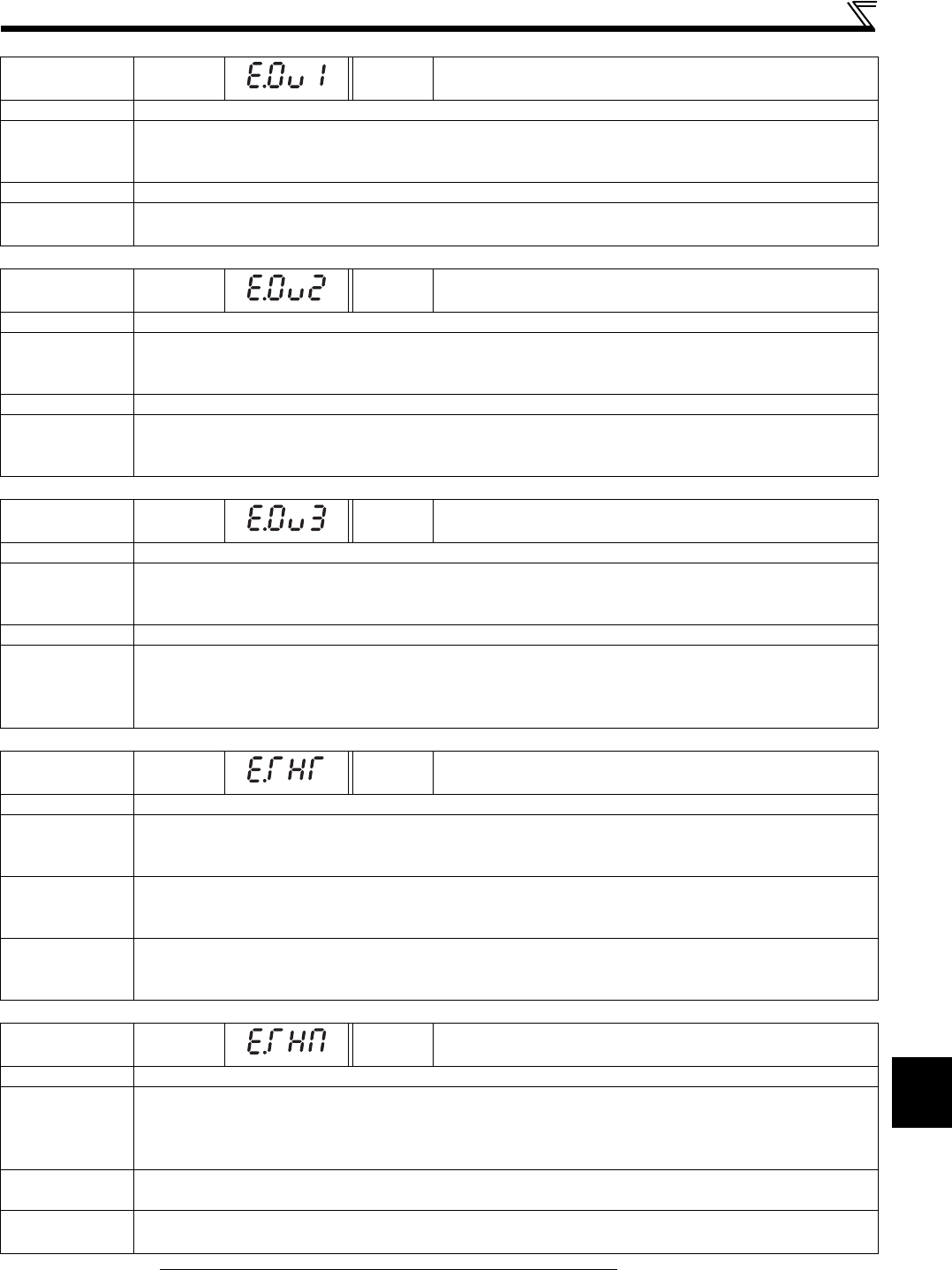

E.OV1

FR-PU07 OV During Acc

Name

Regenerative overvoltage trip during acceleration

Description

If regenerative energy causes the drive unit's internal main circuit DC voltage to reach or exceed the specified value,

the protective circuit is activated and the drive unit trips. The circuit may also be activated by a surge voltage

produced in the power supply system.

Check point

Check for too slow acceleration. (e.g. during downward acceleration in vertical lift load)

Corrective

action

Decrease the acceleration time.

Check that regeneration avoidance function (Pr.882, Pr.883, Pr.885, Pr.886) is used. (Refer to page 242)

Operation panel

indication

E.OV2

FR-PU07 Stedy Spd OV

Name

Regenerative overvoltage trip during constant speed

Description

If regenerative energy causes the drive unit's internal main circuit DC voltage to reach or exceed the specified value,

the protective circuit is activated to stop the drive unit output. The circuit may also be activated by a surge voltage

produced in the power supply system.

Check point

Check for sudden load change.

Corrective

action

Keep load stable.

Check that regeneration avoidance function (Pr.882, Pr.883, Pr.885, Pr.886) is used. (Refer to page 242)

Use the brake resistor, brake unit or power regeneration common converter (FR-CV) as required.

Operation panel

indication

E.OV3

FR-PU07 OV During Dec

Name

Regenerative overvoltage trip during deceleration or stop

Description

If regenerative energy causes the drive unit's internal main circuit DC voltage to reach or exceed the specified value,

the protective circuit is activated to stop the drive unit output. The circuit may also be activated by a surge voltage

produced in the power supply system.

Check point

Check for sudden speed reduction.

Corrective

action

Increase the deceleration time. (Set the deceleration time which matches the moment of inertia of the load)

Longer the brake cycle.

Use regeneration avoidance function (Pr.882, Pr.883, Pr.885, Pr.886). (Refer to page 242)

Use the brake resistor, brake unit or power regeneration common converter (FR-CV) as required.

Operation panel

indication

E.THT

FR-PU07 Inv. Overload

Name

Drive unit overload trip (electronic thermal relay function)

Description

If the temperature of the output transistor element exceeds the protection level under the condition that a current not

less than the rated drive unit current flows and overcurrent trip does not occur (230% or less), the electronic thermal

relay activates to stop the drive unit output. (Overload capacity 150% 60s, 200% 3s)

Check point

Check that acceleration/deceleration time is not too short.

Check the motor for use under overload.

Check for too high surrounding air temperature.

Corrective

action

Increase acceleration/deceleration time.

Reduce the load weight.

Set the surrounding air temperature to within the specifications.

Operation panel

indication

E.THM

FR-PU07 Motor Ovrload

Name

Motor overload trip (electronic thermal relay function)

Description

The electronic thermal relay function in the drive unit detects motor overheat due to overload or reduced cooling

capability during low-speed operation and pre-alarm (TH display) is output when the integrated value reaches 85% of

the Pr.9 Electronic thermal O/L relay setting and the protection circuit is activated to stop the drive unit output when the

integrated value reaches the specified value.

Check point

Check the motor for use under overload.

Check that torque limit operation setting is correct.

Corrective

action

Reduce the load weight.

Check that torque limit operation setting is correct. (Refer to page 111)