249

Useful functions

4

PARAMETERS

4.20.4 Current average value monitor signal (Pr.555 to Pr.557)

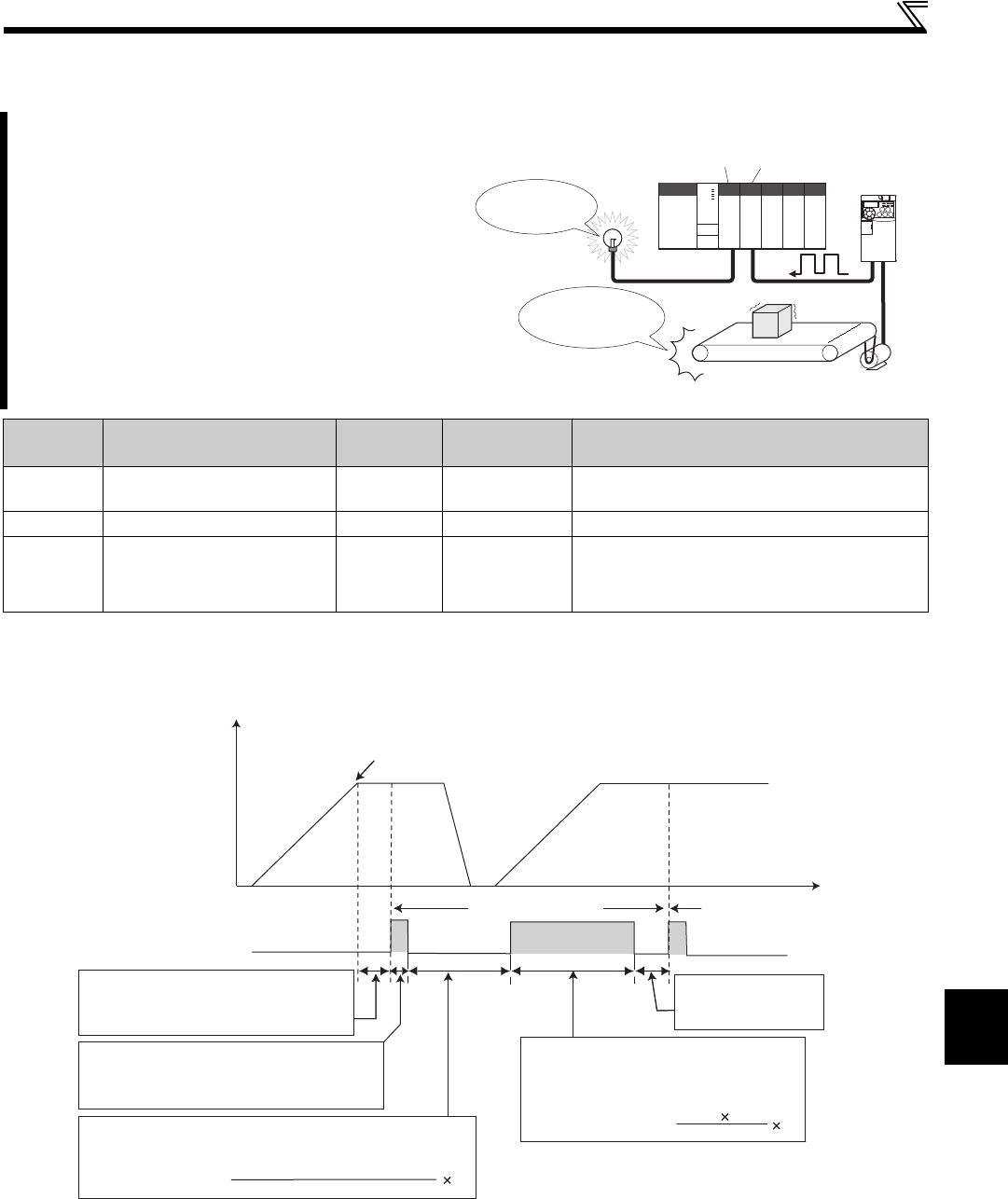

The pulse output of the current average value monitor signal (Y93) is shown above.

For the terminal used for the Y93 signal output, assign the function by setting "93" (positive logic) or "193" (negative logic)

to Pr.190 and Pr.191 (output terminal function selection). The function can not be assigned to Pr.192 ABC terminal function

selection.

1)Setting of Pr.556 Data output mask time

The output current is unstable (transient state) right after the operation is changed from the acceleration/deceleration state

to the constant speed operation. Set the time for not obtaining (mask) transient state data in Pr.556.

The average value of the output current during

constant speed operation and the maintenance timer

value are output as a pulse to the current average

value monitor signal (Y93).

The pulse width output to the I/O module of the

programmable controller or the like can be used as a

guideline due to abrasion of machines and elongation

of belt and for aged deterioration of devices to know

the maintenance time.

The current average value monitor signal (Y93) is

output as pulse for 20s as 1 cycle and repeatedly

output during constant speed operation.

Parameter

number

Name Initial value Setting range Description

555 Current average time

1s 0.1 to 1.0s

Time taken to average the current during start pulse

output (1s).

556 Data output mask time

0s 0 to 20s Time for not obtaining (mask) transient state data.

557

Current average value

monitor signal output

reference current

Rated

motor

current

0 to 500A

Reference (100%) for outputting the signal of the

current average value.

The above parameters can be set when Pr.160 Extended function display selection = "0". (Refer to page 182)

The above parameters allow its setting to be changed during operation in any operation mode even if "0" (initial value) is set in Pr.77 Parameter write

selection.

Refer to page 307 for the rated motor current.

Programmable controller

Output unit Input unit

Maintenance

time

Parts have

reached their life

Drive unit

1) Data output mask time

When the speed has changed to

constant from acceleration/deceleration,

Y93 signal is not output for Pr.556 time.

2) Start pulse

Output as Hi pulse shape for 1s (fixed)

The output currents are averaged during the

time period set in Pr.555.

4) Maintenance timer pulse

The maintenance timer value (Pr.503) is

output as Hi pulse shape for 2 to 9s

(16000h to 72000h)

5) End pulse

Output as low pulse

shape for 1 to 16.5s

Time

Y93 signal

1 cycle (20s)

Next cycle

Rotation speed

From acceleration to constant speed operation

3) Output current average value pulse

The averaged current value is output for 0.5 to 9s

(10 to 180%) during start pulse output.

Signal output time =

Output current average value (A)

Pr.557 (A)

5s

Signal output time =

5s

Pr.503 100h

40000h