240

Special operation and speed control

(7) Adjustment procedure

(8) Calibration example

(A detector of 4mA at 0°C and 20mA at 50°C is used to adjust the room temperature to 25°C under PID control.

The set point is given to across drive unit terminals 2-5 (0 to 5V).)

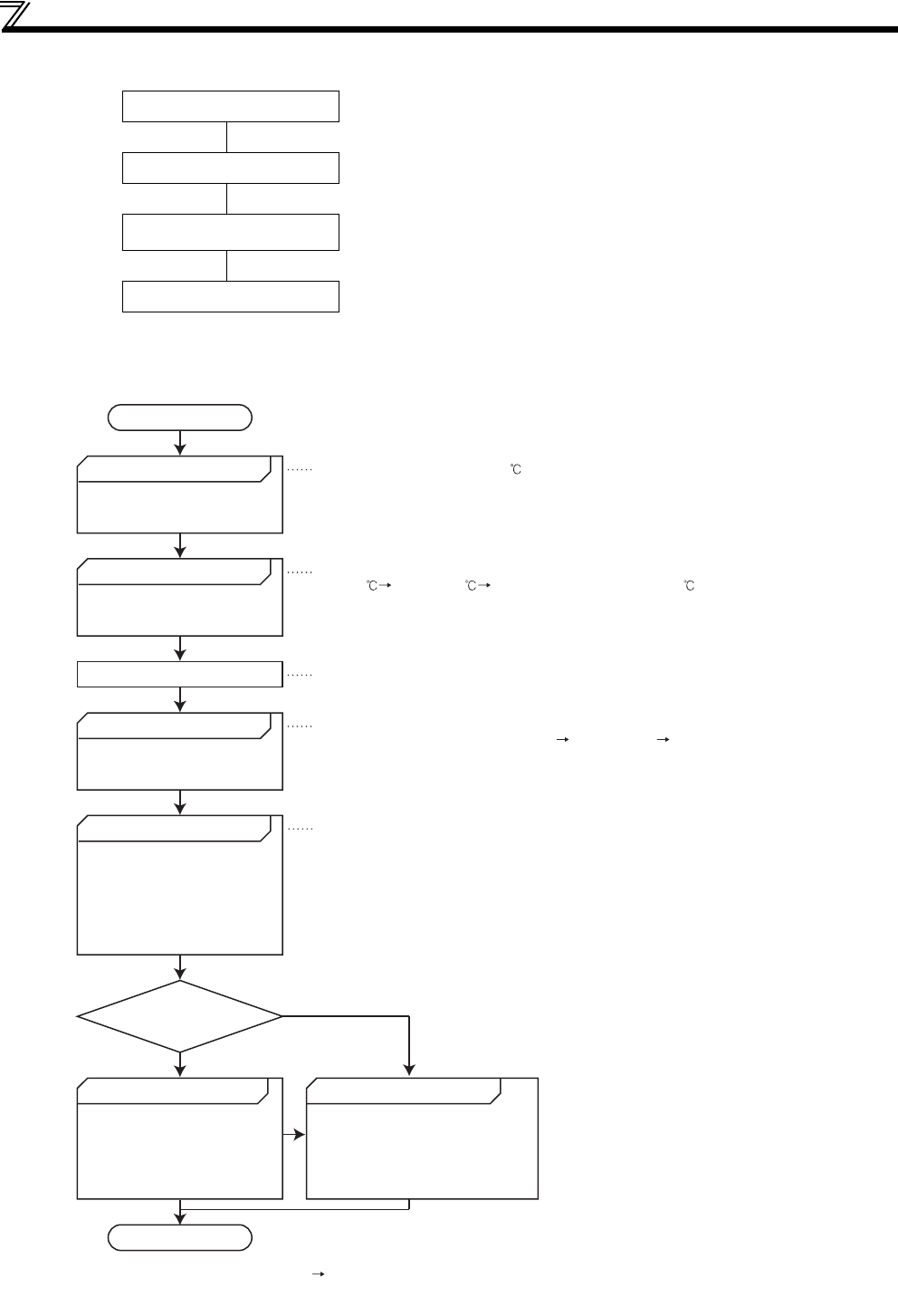

Parameter setting Adjust the PID control parameters, Pr.127 to Pr.134.

Terminal setting

Set the I/O terminals for PID control (Pr.178 to Pr.184 (input terminal

function selection), Pr.190 to Pr.192 (output terminal function selection))

Turn ON the X14 signal.

When X14 signal is not assigned, setting a value other than "0" in

Pr.128 activates PID operation.

Operation

Start

Determination of set point

Determine the set point of

what is desired to be adjusted.

Conversion of set point into %

Calculate the ratio of the set

point to the detector output.

Make calibration.

Setting of set point

Operation

Is the set point stable?

Parameter adjustment Parameter optimization

Adjustment end

Yes

No

∗When calibration

is required

Set the proportional band (Pr.129 )

to a slightly larger value, the

integral time (Pr.130 ) to a

slightly longer time, and the

differential time (Pr.134 ) to "9999"

(no function), and turn ON the

start signal.

To stabilize the measured value,

change the proportional band

(Pr.129 ) to a larger value, the

integral time (Pr. 130 ) to a slightly

longer time, and the differential

time (Pr.134 ) to a slightly shorter

time.

While the measured value is stable

throughout the operation status, the

proportional band (Pr.129 ) may be

decreased, the integral time (Pr.130 )

decreased, and the differential time

(Pr.134 ) increased.

When the parameter unit is used for operation, input the set point (0 to 100%)

in Pr.133.

When performing operation, first set the proportional band (Pr.129 ) to a

slightly larger value, the integral time (Pr.130 ) to a slightly longer time,

and the differential time (Pr.134 ) to "9999" (no function), and while looking at

the system operation, decrease the proportional band (Pr.129 ) and increase

the integral time (Pr.130 ). For slow response system where a deadband

exists, differential control (Pr.134 ) should be turned ON and increased slowly.

Make the following calibration∗ when the target setting input (0 to 5V)

and etector output (4 to 20mA) must be calibrated.

Input a voltage across terminals

2-5 according to the set value %.

Using calibration Pr.902 and Pr.903 (terminal 2) or Pr.904 and Pr.905 (terminal 4),

calibrate the detector output and target setting input.

Make calibration in the PU mode during an drive unit stop.

Set the room temperature to 25 .

Set Pr.128 and turn ON the X14 signal to enable PID control.

Detector specifications

When 0 4mA and 50 20mA are used, the set point 25 is 50%

on the assumption that 4mA is 0% and 20mA is 100%.

When the set point is 50%

As the terminal 2 specifications are 0% 0V and 100% 5V, input

2.5V to the terminal 2 for the set point of 50%.