23

2

WIRING

Control circuit specifications

2.3.3 Wiring of control circuit

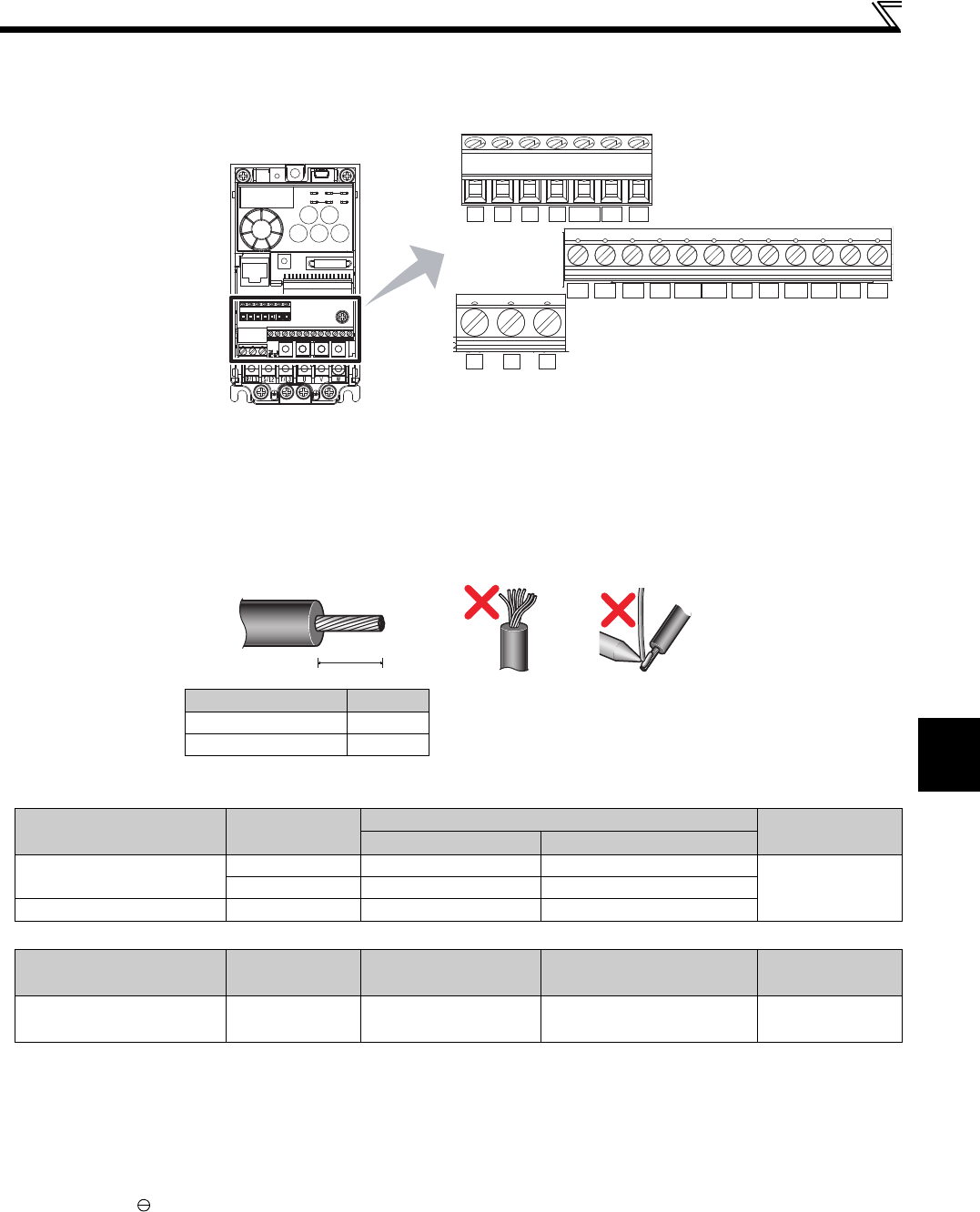

Terminal layout

Wiring method

1) Strip off the sheath of the wire of the control circuit to wire.

Strip off the sheath about the length below. If the length of the sheath peeled is too long, a short circuit may occur

among neighboring wires. If the length is too short, wires might come off.

Wire the stripped wire after twisting it to prevent it from becoming loose. In addition, do not solder it. Use a blade

terminal as necessary.

Blade terminals available on the market: (as of Feb. 2012)

Phoenix Contact Co.,Ltd.

NICHIFU Co.,Ltd.

2) Loosen the terminal screw and insert the wire into the terminal.

3) Tighten the screw to the specified torque.

Undertightening can cause wire disconnection or malfunction. Overtightening can cause a short circuit or malfunction

due to damage to the screw or unit.

Tightening torque: 0.5N·m to 0.6N·m (terminal A, B, C)

0.22N·m to 0.25N·m (other than the above)

Screwdriver: Small flathead screwdriver (Tip thickness: 0.4mm/tip width: 2.5mm)

Terminal screw size

M3: (Terminal A, B, C)

M2: (Other than the above)

Wire stripping length

L(mm)

Terminal A, B, C 6

Other than the above 5

Terminal Screw Size

Wire Size (mm

2

)

Blade Terminal Model Crimping Tool

Name

With Insulation Sleeve Without Insulation Sleeve

M3 (terminal A, B, C)

0.3, 0.5 AI 0,5-6WH A 0,5-6

CRIMPFOX 6

0.75 AI 0,75-6GY A 0,75-6

M2 (other than the above)

0.3, 0.5 AI 0,5-6WH A 0,5-6

Terminal Screw Size

Wire Size (mm

2

)

Blade terminal

product number

Insulation product number

Crimping Tool

Product Number

M3 (terminal A, B, C)

M2 (other than the above)

0.3 to 0.75 BT 0.75-7 VC 0.75 NH 69

SDSD

STF STR

PCSD

RESMRS

RHRMRL

FM

CBA

10 2 5 4 RUN FU SE

L