281

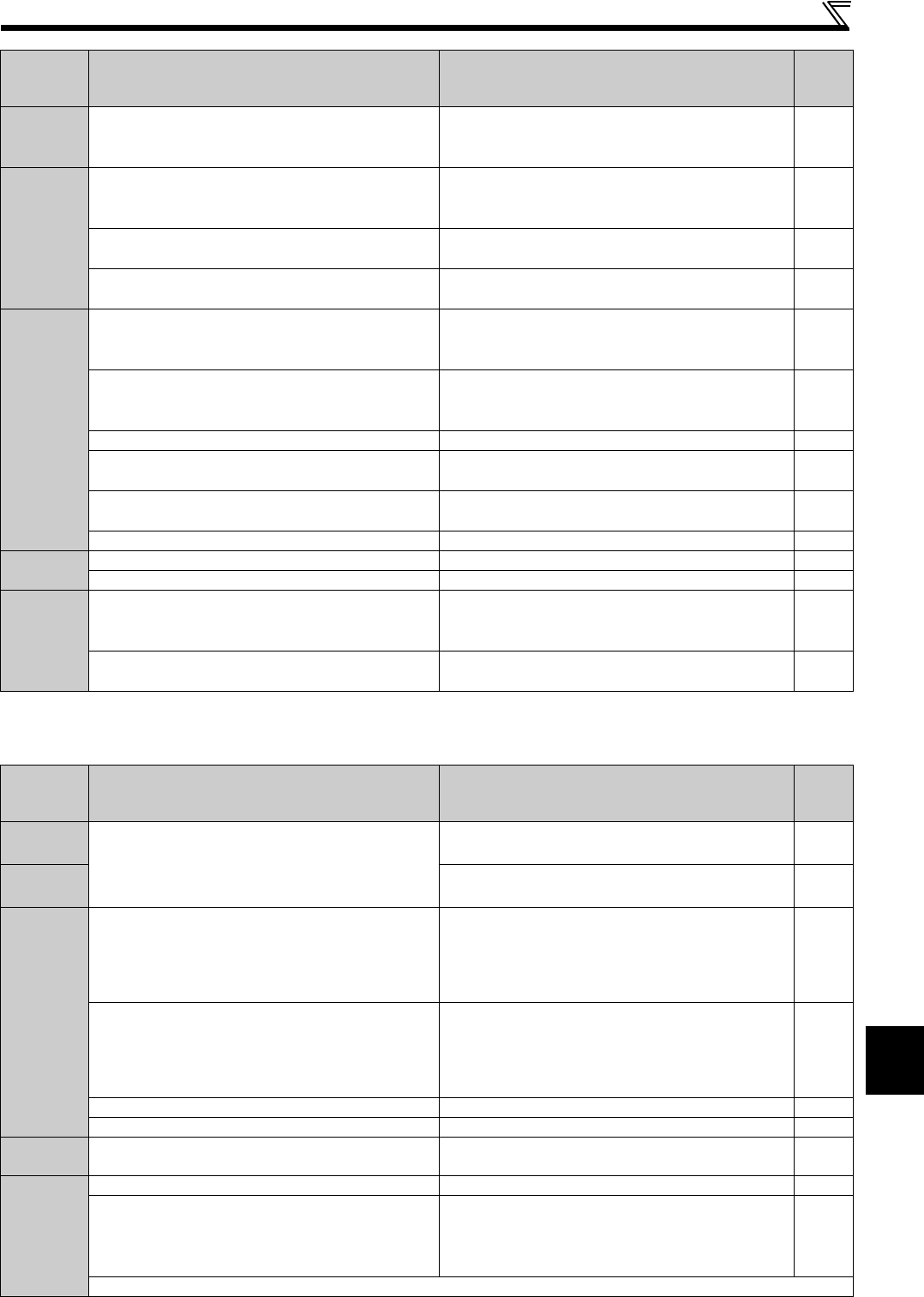

Check first when you have a trouble

5

TROUBLESHOOTING

5.5.2 Motor or machine is making abnormal acoustic noise

Input

Signal

Under position control, the forward rotation stroke end

(LSP) or the reverse rotation stroke end (LSN) signal is

assigned, but is not input.

Turn ON the LSP or LSN signal.

Check the Pr.535 Position control terminal input selection

setting.

100

Parameter

Setting

Pr.78 Reverse rotation prevention selection is set.

Check the Pr.78 setting.

Set Pr.78 when you want to limit the motor rotation to

only one direction.

182

Pr.79 Operation mode selection setting is wrong.

Select the operation mode which corresponds with input

methods of start command and speed command.

188

Bias and gain (calibration parameter C2 to C7) settings

are improper.

Check the bias and gain (calibration parameter C2 to C7)

settings.

173

Parameter

Setting

Pr.13 Starting speed setting is greater than the running

speed.

Set running speed higher than Pr.13.

The drive unit does not start if the speed setting signal is

less than the value set in Pr.13.

128

Speed settings of various running speed (such as

multispeed operation) are zero.

Especially, Pr.1 Maximum setting is zero.

Set the speed command according to the application.

Set Pr.1 higher than the actual speed used.

115

Pr.15 Jog speed setting is lower than Pr.13 Starting speed. Set Pr.15 Jog speed setting higher than Pr.13 Starting speed. 119

Operation mode and a writing device do not match.

Check Pr.79, Pr.338, Pr.339, Pr.551, and select an

operation mode suitable for the purpose.

186,

195

Start signal operation selection is set by the Pr.250 Stop

selection.

Check Pr.250 setting and connection of STF and STR

signals.

142

PM motor test operation is selected. Set "10" in Pr.800 Control method selection. 75

Load

Load is too heavy. Reduce the load.

Shaft is locked. Inspect the machine (motor).

Others

Operation panel display shows an error (e.g. E.OC1).

When any fault occurs, take an appropriate corrective

action, then reset the drive unit, and resume the

operation.

267

Under position control, point table position control

based on the absolute position does not operate.

Perform home position return. 95, 104

Check

Points

Possible Cause Countermeasures

Refer

to

page

Input

Signal

Disturbance due to EMI when speed command is given

from analog input (terminal 2, 4).

Take countermeasures against EMI. 36

Parameter

Setting

Increase the Pr.74 Input filter time constant if steady

operation cannot be performed due to EMI.

172

Parameter

Setting

Resonance occurs. (rotation speed)

Set Pr.31 to Pr.36 (speed jump).

When it is desired to avoid resonance attributable to the

natural speed of a mechanical system, these

parameters allow resonant speeds to be jumped.

Set Pr.862, Pr.863, and Pr.871 (notch filter).

85, 116

Gain adjustment during PID control is insufficient.

To stabilize the measured value, change the proportional

band (Pr.129 ) to a larger value, the integral time (Pr.130 )

to a slightly longer time, and the differential time (Pr.134 )

to a slightly shorter time.

Check the calibration of set point and measured value.

235

Speed control gain is too high. Check Pr.820 Speed control P gain setting. 80

Under position control, position control gain is too high. Check the Pr.422 Position control gain setting. 92

Others

Mechanical looseness

Adjust machine/equipment so that there is no

mechanical looseness.

Motor

Operating with output phase loss Check the motor wiring.

High-frequency tone is heard while the motor is at a

stop.

High-frequency tone may be generated during the MM-

GKR motor driving operation because high frequency

currents are superposed during low-speed operation

and stopping. This is a normal operation.

Please contact your sales representative.

Check

Points

Possible Cause Countermeasures

Refer

to

page