280

Check first when you have a trouble

5.5 Check first when you have a trouble

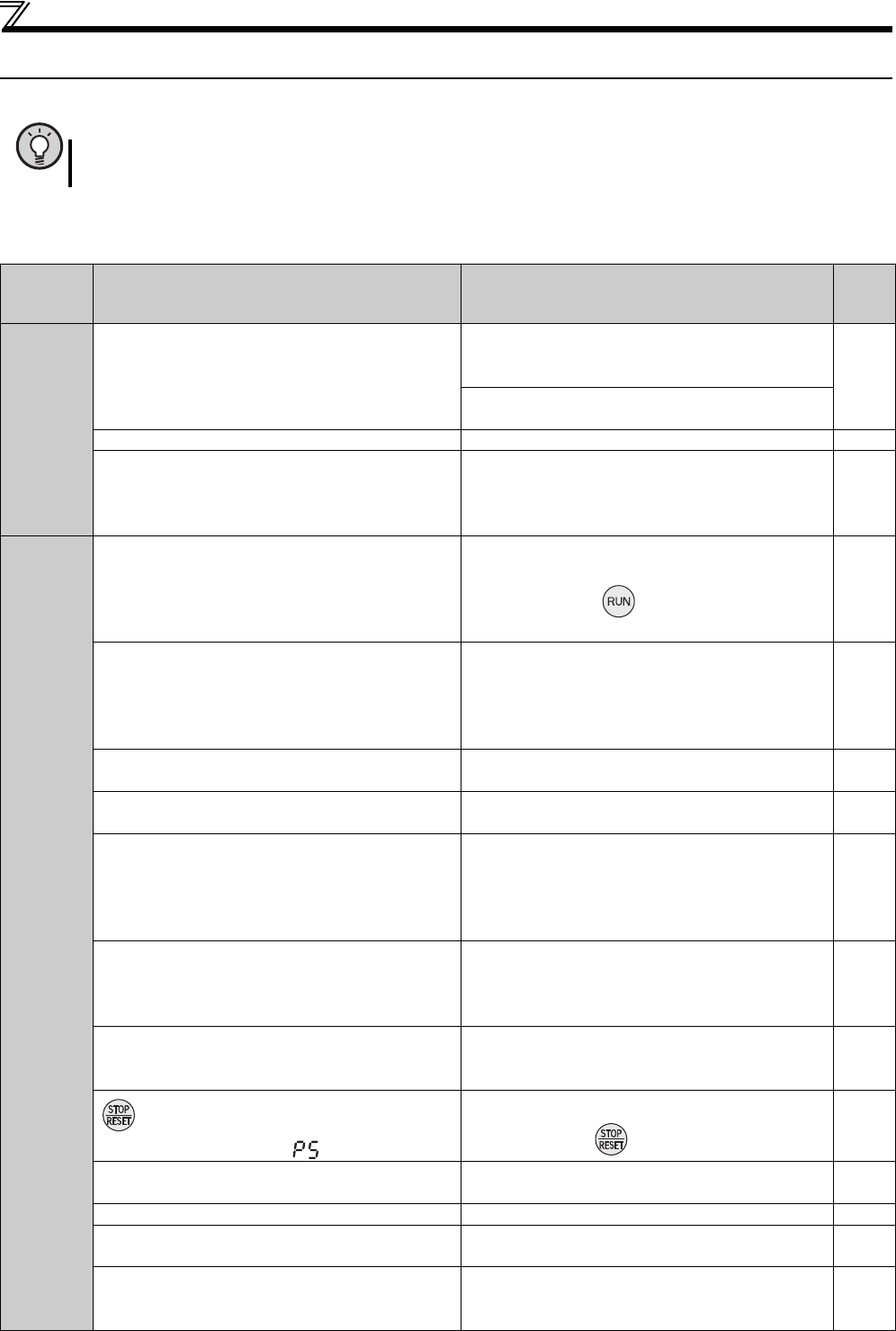

5.5.1 Motor does not start

POINT

If the cause is still unknown after every check, it is recommended to initialize the parameters (initial value) then

set the required parameter values and check again.

Check

Points

Possible Cause Countermeasures

Refer

to

page

Main

Circuit

Appropriate power supply voltage is not applied.

(Operation panel display is not provided.)

Power ON moulded case circuit breaker (MCCB), an

earth leakage circuit breaker (ELB), or a magnetic

contactor (MC).

Check for the decreased input voltage, input phase loss,

and wiring.

Motor is not connected properly. Check the wiring between the drive unit and the motor. 15

The jumper across P/+ to P1 is disconnected.

Securely fit a jumper across P/+ to P1.

To use a DC reactor (FR-HEL) or Filterpack, remove the

jumper across the terminals P/+ and P1, then connect

the DC reactor or Filterpack.

32

Input

Signal

Start signal is not input.

Check the start command source, and input a start

signal.

PU operation mode:

External operation mode : STF/STR signal

188

Both the forward and reverse rotation start signals (STF,

STR) are input simultaneously.

Turn ON only one of the forward and reverse rotation

start signals (STF or STR).

If the STF and STR signals are turned ON

simultaneously in the initial setting, a stop command is

given.

168

Speed command is zero.

Check the speed command source and enter a speed

command.

188

AU signal is not ON when terminal 4 is used for speed

setting.

Turn ON the AU signal.

Turning ON the AU signal activates terminal 4 input.

168

Output stop signal (MRS) or reset signal (RES) is ON.

(RUN LED on the operation panel flickers while MRS

signal is ON.)

Turn MRS or RES signal OFF.

Drive unit starts the operation with a given start

command and a speed command after turning OFF

MRS or RES signal.

Before turning OFF, ensure the safety.

18

Jumper connector of sink - source is wrongly selected.

Check that the control logic switchover jumper connector

is correctly installed.

If it is not installed correctly, input signal is not

recognized.

21

Voltage/current input switch is not correctly set for

analog input signal (0 to 5V/0 to 10V, 4 to 20mA).

Set Pr.73, Pr.267, and a voltage/current input switch

correctly, then input an analog signal in accordance with

the setting.

18

was pressed.

(Operation panel indication is (PS).)

During the External operation mode, check the method

of restarting from a input stop from PU.

270

Two-wire or three-wire type connection is wrong.

Check the connection.

Connect STOP signal when three-wire type is used.

142

Servo-ON signal (SON) is assigned, but is not input. Turn ON the SON signal. 131

Under position control, servo-ON signal (SON) or pre-

excitation signal (LX) is not input.

Assign the SON signal or the LX signal to an input

terminal, and turn ON the signal.

131

Under position control, position control sudden stop

signal (X87) is input.

Turn OFF the X87 signal.

Check the Pr.535 Position control terminal input selection

setting.

100