298

Measurement of main circuit voltages, currents and powers

6.2.3 Measurement of currents

Use moving-iron type meters on the input side of the drive unit, use approximate effective-value rectifier type AC ammeter on

the output side.

Since current on the drive unit input side tends to be unbalanced, measurement of three phases is recommended. Correct

value can not be obtained by measuring only one or two phases. On the other hand, the unbalanced ratio of each phase of

the output side current should be within 10%.

When a clamp ammeter is used, always use an effective value detection type. A mean value detection type produces a large

error and may indicate an extremely smaller value than the actual value. The value monitored on the operation panel is

accurate if the output frequency varies, and it is recommended to monitor values (provide analog output) using the operation

panel.

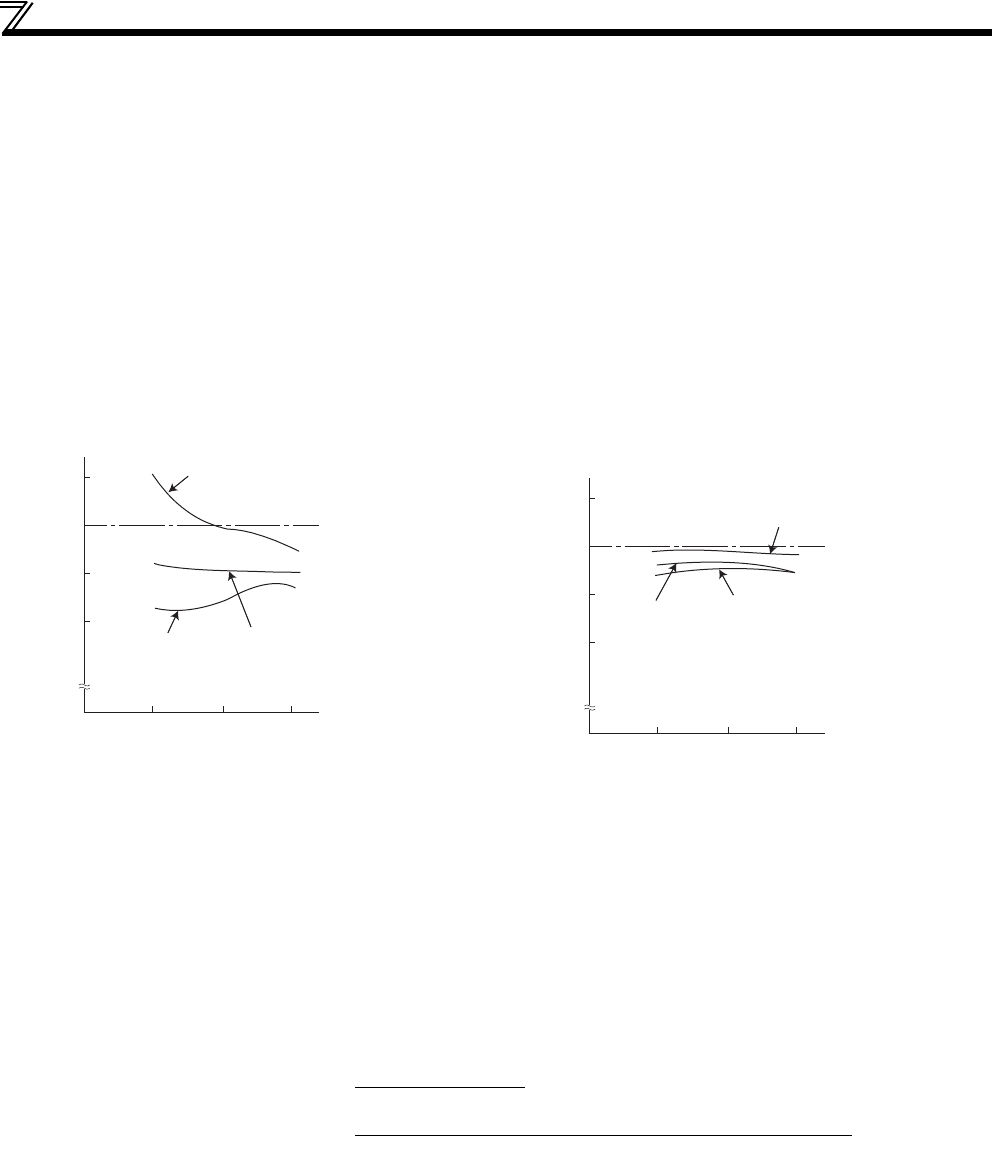

Examples of process value differences produced by different measuring meters are shown below.

6.2.4 Use of CT and transducer

A CT may be used in both the input and output sides of the drive unit, but the one used should have the largest possible VA

ability because an error will increase if the frequency gets lower.

When using a transducer, use the effective value calculation type which is immune to harmonics.

6.2.5 Measurement of drive unit input power factor

Calculate using effective power and apparent power. A power-factor meter can not indicate an exact value.

6.2.6 Measurement of converter output voltage (across terminals P/+ and N/-)

[Measurement conditions]

Value indicated by moving-iron type ammeter is 100%.

Example of measuring input current

[Measurement conditions]

The value indicated by an approximate effective-value

rectifier type AC ammeter is 100%.

Example of measuring output current

Total power factor of the drive unit =

Effective power

Apparent power

=

3-phase input power found by 3-wattmeter method

V (power supply voltage) I (input current effective value)

The output voltage of the converter is developed across terminals P/+ and N/- and can be measured with a moving-coil type

meter (tester). Although the voltage varies according to the power supply voltage, approximately 270VDC to 300VDC is

output when no load is connected and voltage decreases during driving load operation.

When energy is regenerated from the motor during deceleration, for example, the converter output voltage rises to nearly

400VDC to 450VDC maximum.

120

100

80

60

0

60Hz40

20

%

Moving-iron

type

Clamp-on

wattmeter current measurement

Clamp meter

Clip AC power meter

120

100

80

60

0

60Hz40

20

%

Approximate

effective-value

rectifier type

Clip AC power mete

r

Clamp-on

wattmeter current

measurement

Clamp meter