3. Setup

3 - 35

High-gain specifications

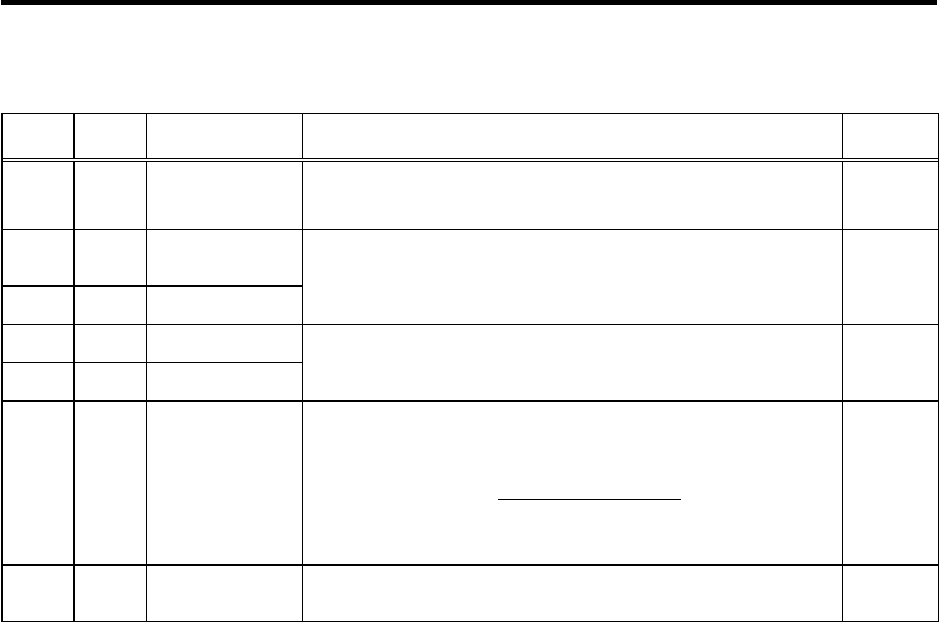

No. Abbrev. Parameter name Explanation

Setting range

(Unit)

SV060 TLMT

Collision detection

level

When using the collision detection function, set the collision detection level

during the G0 feeding.

If "0" is set, none of the collision detection function will work.

0 to 999

(Stall [rated]

current %)

SV061 DA1NO

D/A output channel

1 data No.

Input the data number you wish to output to D/A output channel.

In the case of MDS-C1-V2, set the axis on the side to which the data will

not be output to "-1".

SV062 DA2NO

D/A output channel

2 data No.

-1 to 127

SV063 DA1MPY

D/A output channel

1 output scale

Set the scale with a 1/256 unit.

When "0" is set, output is done with the standard output unit.

SV064 DA2MPY

D/A output channel

2 output scale

-32768 to

32767

(Unit: 1/256)

Set the spring constant of the tool end compensation.

In the semi-closed loop control, the tool end compensation amount is

calculated with the following equation.

F (mm/min)

2

× SV065

Compensation amount=

R (mm)

× 10

9

(

µm)

SV065 TLC

Tool end

compensation

spring constant

When not using, set to "0".

-32768 to

32767

SV066

:

SV080

System setting

parameter

These parameters are set automatically by the NC system.

Parameters with an asterisk * in the abbreviation, such as PC1*, are validated with the NC power turned ON again.