1. Installation

1 - 17

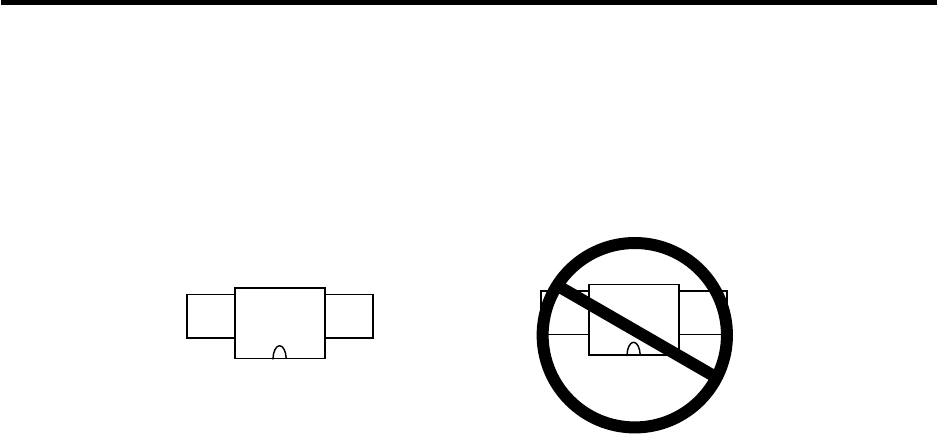

(3) Magnet and sensor installation directions

• Install so that the magnet's reference hole and sensor's reference notch are aligned.

(Standard/high-speed standards)

• Install so that the magnet's N pole comes to the left side when the sensor's reference notch is

faced downward. (High-speed compact/high-speed ring)

(4) Cautions

[1] Do not apply impacts on the magnet. Do not install strong magnets near the magnet.

[2] Sufficiently clean the surrounding area so that iron chips and cutting chips do not adhere to the

magnet. Demagnetize the round disk before installing.

[3] Securely install the magnet onto the spindle with an M4 screw. Take measures to prevent

screw loosening as required.

[4] Balance the entire spindle rotation with the magnet installed.

[5] Install a magnet that matches the spindle's rotation speed.

[6] When installing the magnet onto a rotating body's plane, set the speed to 6,000r/min or less.

[7] Install so that the center line at the end of the head matches the center of the magnet.

[8] The BKO-C1730 is not an oil-proof product. Make sure that oil does not come in contact with

BNO-C1730 or BKO-C1810.

[9] When connecting to the spindle drive unit, wire so that the effect of noise is suppressed.

N S

|

Reference notch

Sensor

Magnet

S N

|

Reference notch

Sensor

Magnet