Appendix 2. Compliance to EC Directives

A2 - 4

(6) Selecting the wire size for EC Directive compliance

To comply with the EC Directives, select the wire size from the following table using each drive

unit's capacity as a reference.

The wire types are as follow.

PVC : Polyvinyl chloride

EPR : Ethylene polypropylene

SIR : Silicon rubber

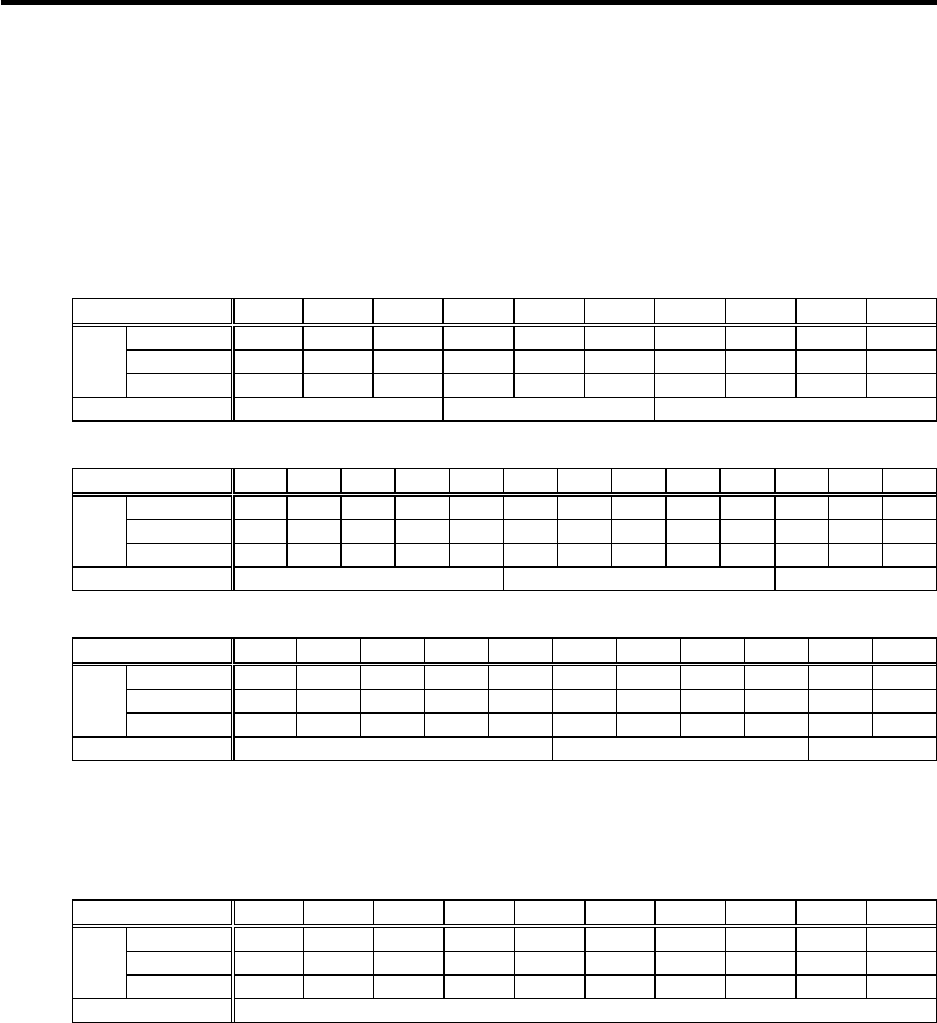

[1] MDS-C1-CV (L1, L2, L3, PE) (The unit sizes are all mm

2

)

Type (MDS-C1-) CV-37 CV-55 CV-75 CV-110 CV-150 CV-185 CV-220 CV-260 CV-300 CV-370

PVC 2.5 2.5 4 6 10 16 25 35 50 70

EPR 1.5 2.5 4 6 10 16 25 35 35 50

Wire

SIR

1.0 1.5 2.5 4 6 10 16 16 25 25

Terminal screw size M4 M5 M8

[2] MDS-C1-SP (U, V, W, PE)

Type (MDS-C1-)

SP-04 SP-075 SP-15 SP-22 SP-37 SP-55 SP-75 SP-110 SP-150 SP-185 SP-220 SP-260 SP-300

PVC 1.0 1.0 1.0 1.0 1.5 2.5 4 6 10 16 25 35 70

EPR 1.0 1.0 1.0 1.0 1.5 2.5 4 6 10 16 25 35 50

Wire

SIR

1.0 1.0 1.0 1.0 1.0 1.0 2.5 4 6 10 10 16 25

Terminal screw size M4 M5 M8

[3] MDS-C1-V1/V2 (U, V, W, PE)

Type (MDS-C1-) V1-01 V1-03 V1-05 V1-10 V1-20 V1-35 V1-45 V1-70 V1-90 V1-110 V1-150

PVC 1.0 1.0 1.0 1.0 1.5 2.5 4 6 10 25 35

EPR 1.0 1.0 1.0 1.0 1.0 1.5 4 6 10 16 25

Wire

SIR

1.0 1.0 1.0 1.0 1.0 1.0 2.5 2.5 4 10 16

Terminal screw size M4 M5 M8

[4] Wire size for L11 and L21 link bar

Select a 1.5mm

2

wire or larger regardless of the capacity. (This also applies to the wire

between NFB-L11 and L21.)

[5] Wire size for L+ and L- link bar (For unified sizes)

Type (MDS-C1-) CV-37 CV-55 CV-75 CV-110 CV-150 CV-185 CV-220 CV-260 CV-300 CV-370

PVC 2.5 2.5 6 10 16 25 35 50 70 -

EPR 1.5 2.5 4 10 16 25 35 35 70 70

Wire

SIR

1.0 1.5 2.5 4 10 10 16 25 35 35

Terminal screw size M6

* The wire sizes in the above table comply with EN60204 under the following conditions.

• Ambient temperature 40°C

• Wire laid along wall or in open cable tray

When using under other conditions, refer to EN60204 Appendix 5 and Appended Material C.