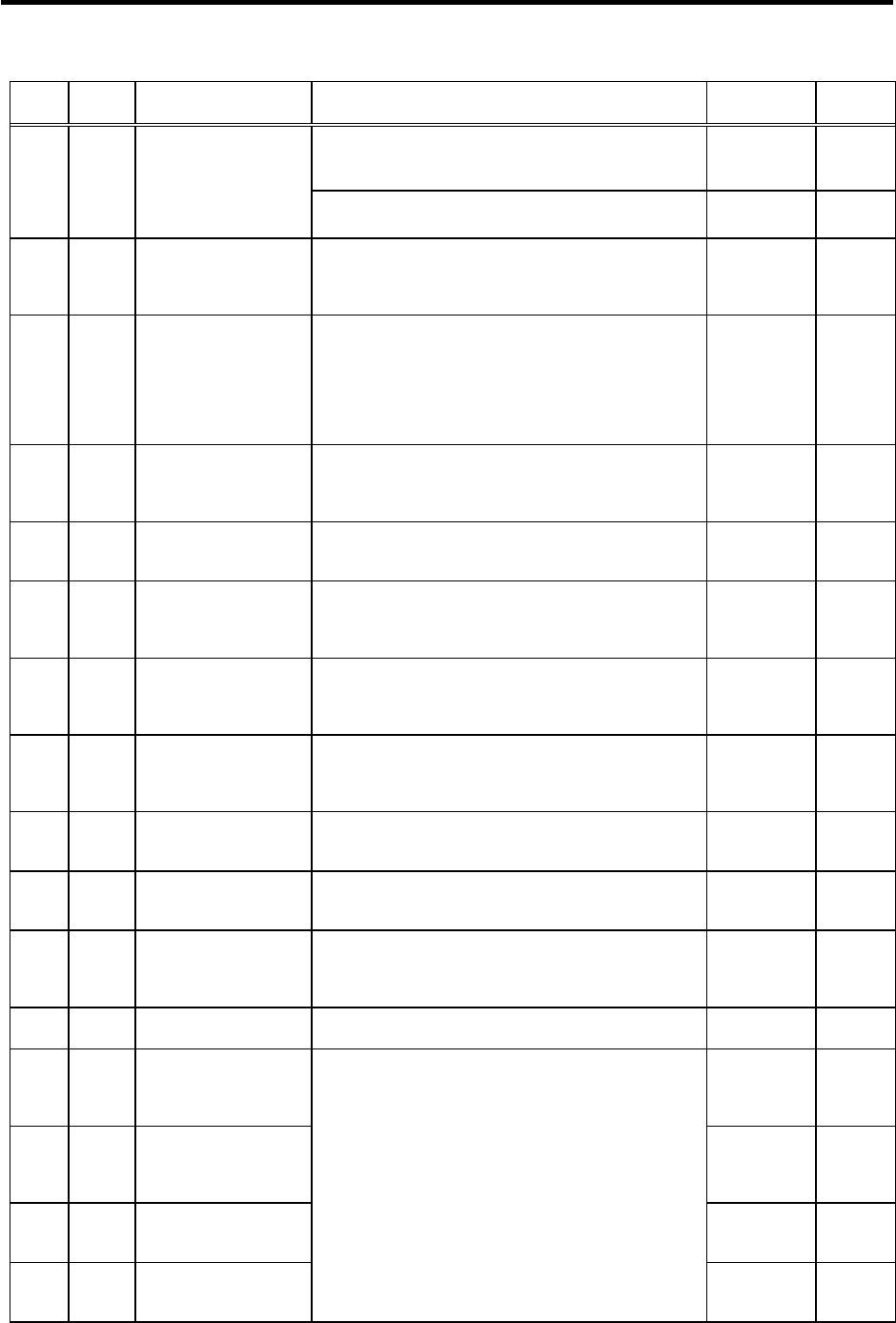

3. Setup

3 - 100

No. Abbr. Parameter name Details

Setting range

(Unit)

Standard

setting

<For MDS-C1-SP/SPH/SPM>

Set to reduce the noise generated from the spindle motor

Set the band of the low path filter

0 to 2250

(rad/s)

0

SP213 LPF

Low path filter

<For MDS-C1-SPX/SPHX>

Not used. Set to "0".

0 0

SP214 TZRN

Synchronized tapping

control

zero point return speed

This parameter is valid when SP193 (SPECT)/bit E is set

to "0".

Set the zero point return speed used when the speed loop

changes to the position loop.

0 to 500

(r/min)

50

SP215 TPDT

Synchronized tapping

control

zero point return

deceleration rate

This parameter is valid when SP193 (SPECT)/bit E is set

to "0".

Set the deceleration rate where the machine starts to

decelerate when it returns to the target stop point during

synchronized tapping zero point return.

When the machine tends to overshoot at the stop point

set a smaller value.

0 to 10000

(pulse)

1

SP216 TPST

Synchronized tapping

control

zero point return shift

amount

This parameter is valid when SP193 (SPECT)/bit E is set

to "0".

Set the synchronized tapping zero point position.

0 to 4095 0

SP217 TINP

Synchronized tapping

control

in-position width

Set the position error range for output of the in-position

during synchronized tapping control.

1 to 2880

(1/16 deg)

16

SP218 TODR*

Synchronized tapping

control

excessive error width

Set the excessive error width during synchronized

tapping.

0 to 32767

(pulse)

(1 pulse =

0.088 deg)

32767

SP219 IQGT*

Synchronized tapping

control

current loop gain

magnification 1

Set the magnification of current loop gain (torque

component) during synchronized tapping control.

1 to 1000 (%) 100

SP220 IDGT*

Synchronized tapping

control

current loop gain

magnification 2

Set the magnification of current loop gain (excitation

component) during synchronized tapping control.

1 to 1000 (%) 100

SP221 PG2T

Synchronized tapping

control

position loop gain 2

Set the second position loop gain when high-gain control

is applied during synchronized tapping control.

When this parameter is not used, set to "0".

0 to 999

(rad/s)

0

SP222 PG3T

Synchronized tapping

control

position loop gain 3

Set the third position loop gain when high-gain control is

applied during synchronized tapping control.

When this parameter is not used, set to "0".

0 to 999

(rad/s)

0

SP223 SPDV Speed monitor speed

Set the spindle limit speed in the door open state.

(Invalid when 0 is set.)

If the spindle end speed exceeds this setting value when

the door is open, the speed monitor error (5E) will occur.

0 to 800

(r/min)

0

SP224 SPDF Speed monitor time

Set the time (continuous) to detect alarms.

(Detected instantly when 0 is set.)

0 to 2813

(3.5 ms)

0

SP225 OXKPH

Position loop gain

magnification after

orientation completed

(H coil)

0 to 2560

(1/256-fold)

0

SP226 OXKPL

Position loop gain

magnification after

orientation completed

(L coil)

0 to 2560

(1/256-fold)

0

SP227 OXVKP

Speed loop proportional

gain magnification after

orientation completed

0 to 2560

(1/256-fold)

0

SP228 OXVKI

Speed loop cumulative

gain magnification after

orientation completed

If gain changeover is valid (SP097: SPEC0/bitC=1) during

orientation control, set the magnification of each gain

changed to after orientation completed.

0 to 2560

(1/256-fold)

0

Parameters with an asterisk * in the abbreviation, such as OSP*, are validated with the NC power turned ON again.