Appendix 1. Cable and Connector Specifications

A1 - 4

Appendix 1-1-2 Flexible conduits

Basically, splash proofing can be ensured if cab-tire cable and connectors with IP65 or higher

specifications are used. However, to further improve the oil resistance (chemical resistance to oil),

weather resistance (resistance to the environment when used outdoors, etc.), durability, tensile strength,

flattening strength, etc., run the cable through a flexible conduit when wiring.

The following shows an example of a flexible conduit. Contact the connector maker for more

information.

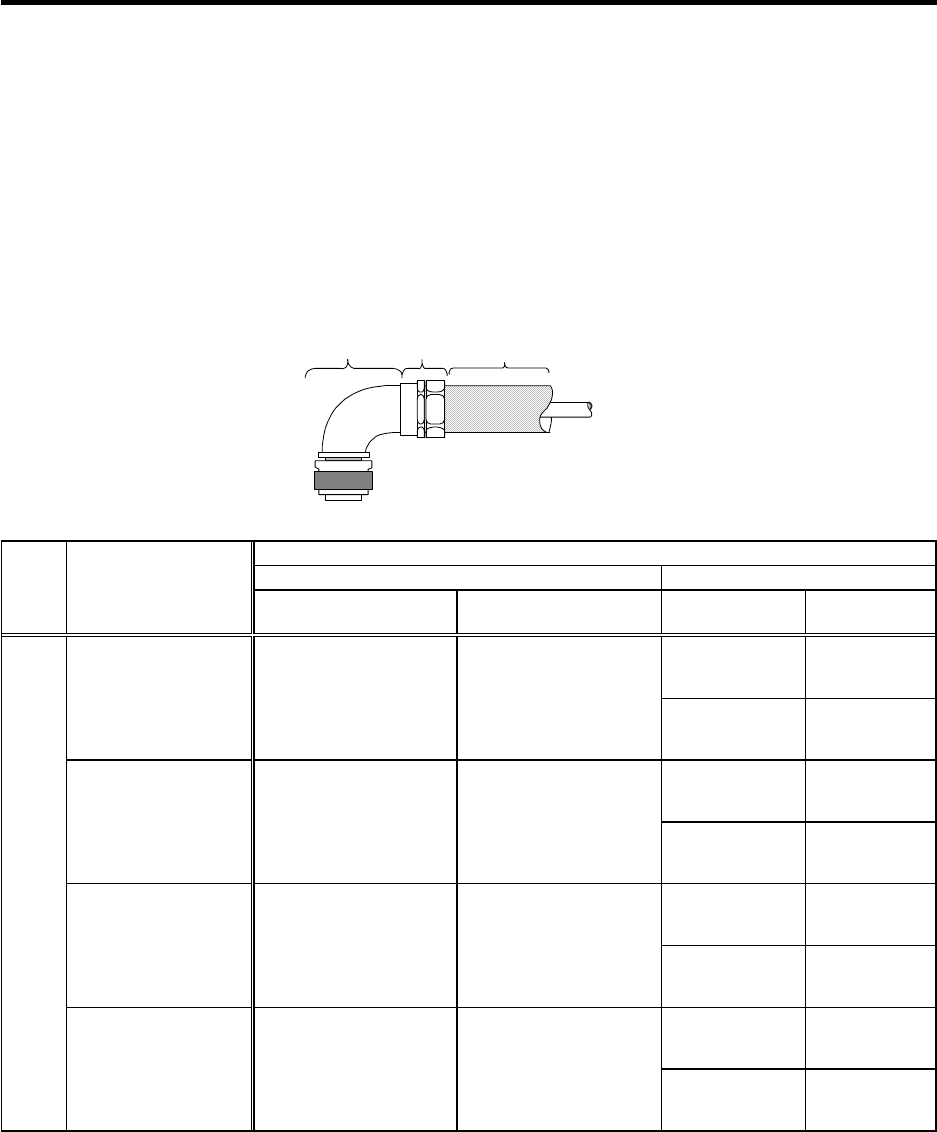

(1) Method for connecting to a connector with back shell

Connector with

back shell

Connector

for conduit

Flexible conduit

Cable

Model

DDK Nippon Flex

Appli-

cation

Applicable motors

Connector (straight) Connector (angle)

Connector for

conduit

Flexible

conduit

RCC-103CA18

VF-03

(Min. inside

diameter: 10.6)

For

power

HA053N, HA13N

HA23N, HA33N

CE05-6A18-12SD-B-BSS CE05-8A18-12SD-B-BAS

RCC-104CA18

VF-04

(Min. inside

diameter: 14)

RCC-104CA2022

VF-04

(Min. inside

diameter: 14)

HC52, HC102, HC152

HC53, HC103, HC153

HC103R, HC153R,

HC203R

CE05-6A22-23SD-B-BSS CE05-8A22-23SD-B-BAS

RCC-106CA2022

VF-06

(Min. inside

diameter: 19)

RCC-106CA2428

VF-06

(Min. inside

diameter: 19)

HC202, HC352, HC452

HC203, HC353

HC353R, HC503R

CE05-6A24-10SD-B-BSS CE05-8A24-10SD-B-BAS

RCC-108CA2428

VF-08

(Min. inside

diameter: 24.4)

RCC108CA32

VF-08

(Min. inside

diameter: 24.4)

HC702, HC902

HC453, HC703

CE05-6A32-17SD-B-BSS CE05-8A32-17SD-B-BAS

RCC110CA32

VF-10

(Min. inside

diameter: 33.0)

(Note) None of the parts in this table can be ordered from Mitsubishi Electric Corp.