1. Installation

1 - 21

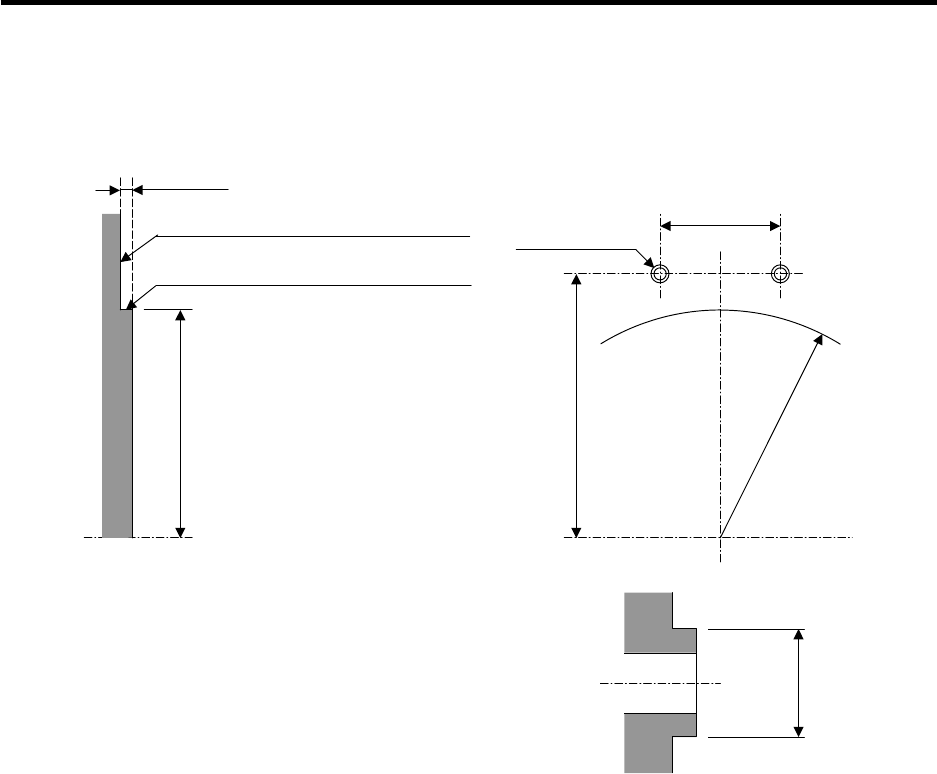

[8] With the sensor installation seat's R section butted against the notched fitting section, fix the

sensor installation seat with a mounting screw (M5 x 0.8 screws). A locking agent should be

applied on the mounting screw before it is tightened.

[9] When using the specifications (TS1860N2770,

TS1860N2776, TS1860N2183, TS1860N2187) with

installation plate (ring) for the sensor section,

provide a notched fitting section on the machine side

as shown on the right, and fit the sensor installation

plate's ø108H5 here. The gap does not need to be

adjusted when using the installation plate.

[10] Make sure that force is not constantly applied on the

sensor's lead wires.

(3) Installing the PCB section

[1] Install the PCB where it will not be subject to water or oil, etc.

[2] Drill two ø11mm or smaller installation seats, and fix the PCB with pan head screws (M5 × 0.8

screws).

[3] Provide a space of 25mm from the installation surface to treat the lead wires for the intermediate

connector.

[4] Select the minimum required length for the lead wires from the sensor to the intermediate

connector, and wire them as far away from other power wires as possible.

[5] Make sure that force is not constantly applied on the PCB lead wire connections.

[6] The check pins on the PCB could break if excessive force is applied.

Installing the sensor with

Installation plate (ring)

ø 108

-0.005

-0.020

[

Unit: mm

]

3.5mm or less

Butt the R section of the sensor installation seat

a

g

ainst here

Butt the back side of the sensor installation

seat against here

Notched section's

outer diameter

2-M5

×

0.8 screw

Notched section's

outer diameter

29mm

Outline

drawing

designated

dimensions

Shape of notched fitting section